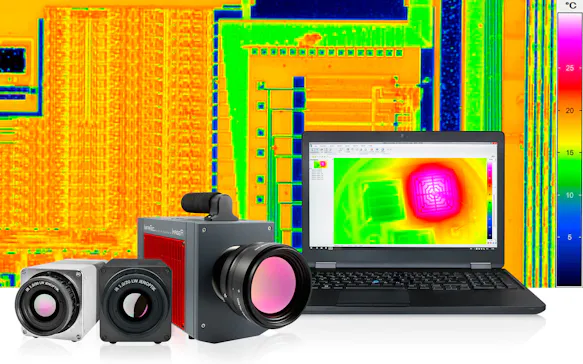

Thermography in Electronics and Electrical Engineering

The use of infrared thermography in electronics and electrical industry allows contactless measurement of surface temperatures with an infrared camera without contacting temperature sensors. It is an elegant, non-invasive optical temperature measurement method for simultaneous and temporally high-resolution detection of a number of measurement points.

Infrared Camera Enables Contactless Measurement in Electronics

The thermographic inspection of electronic components and assemblies is an established test procedure for failure detection and quality management – from the development of first prototypes to serial production. This enables, for example, the following to be detected:

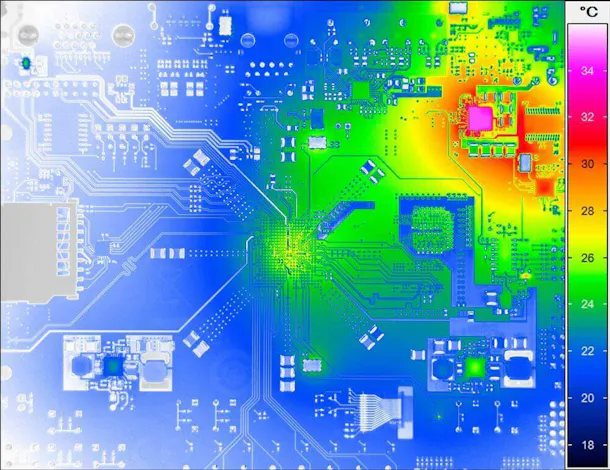

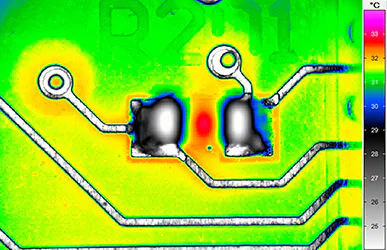

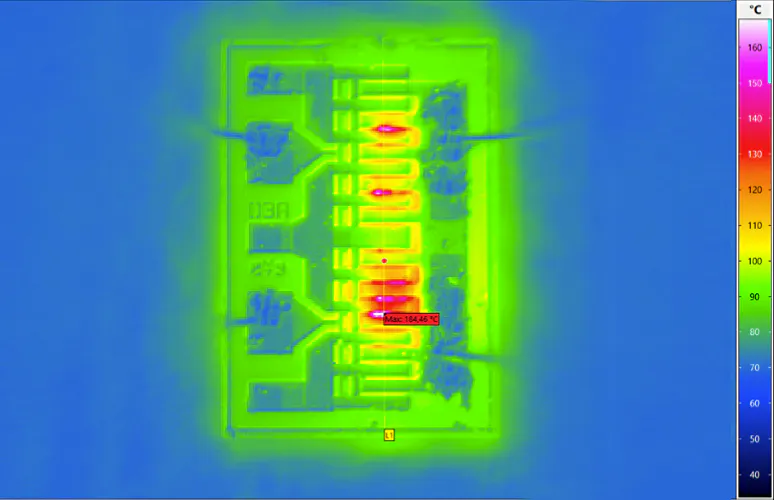

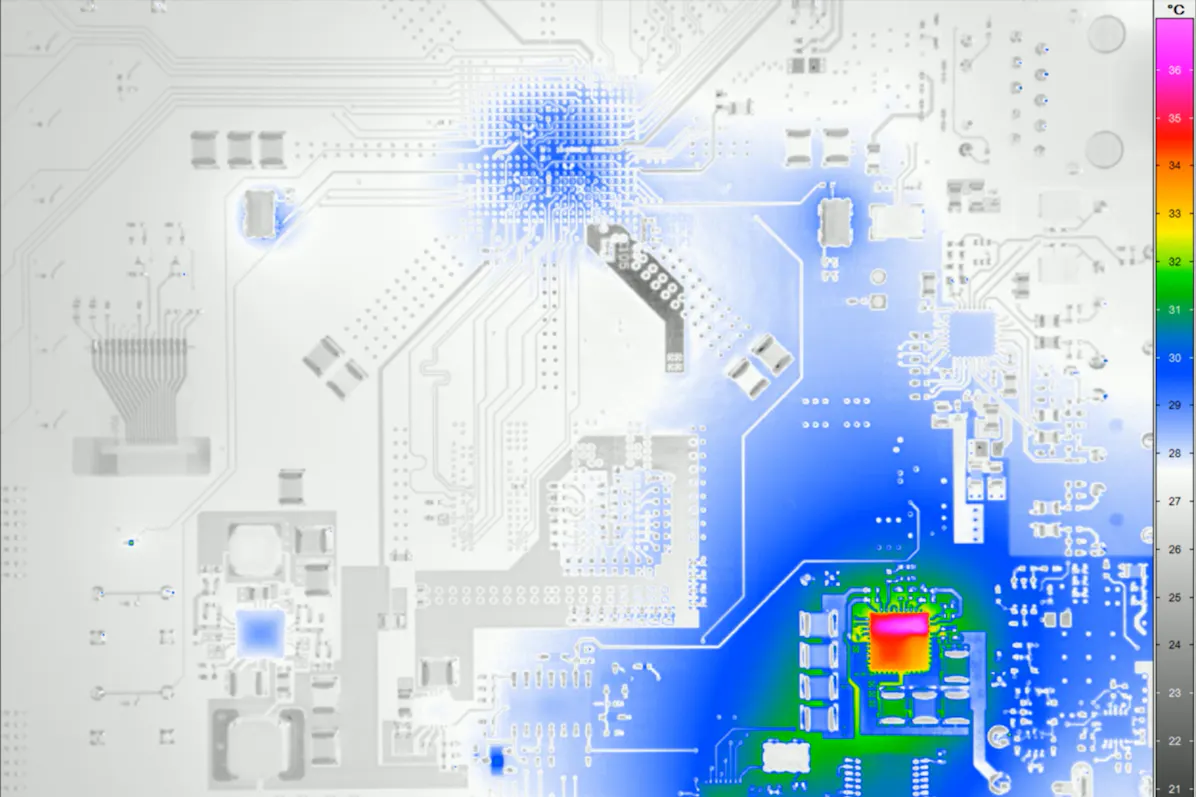

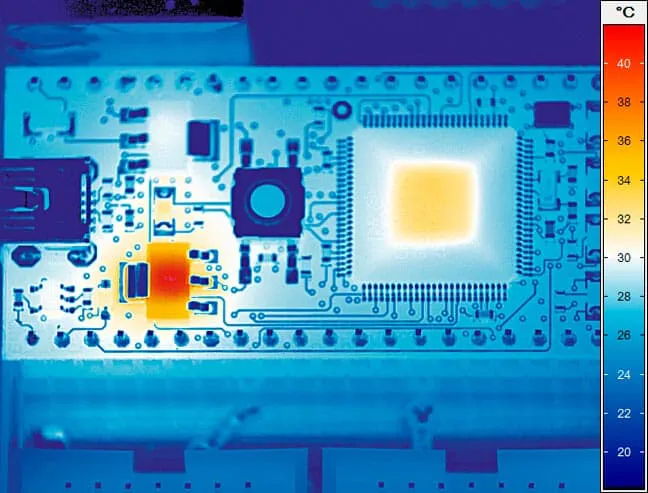

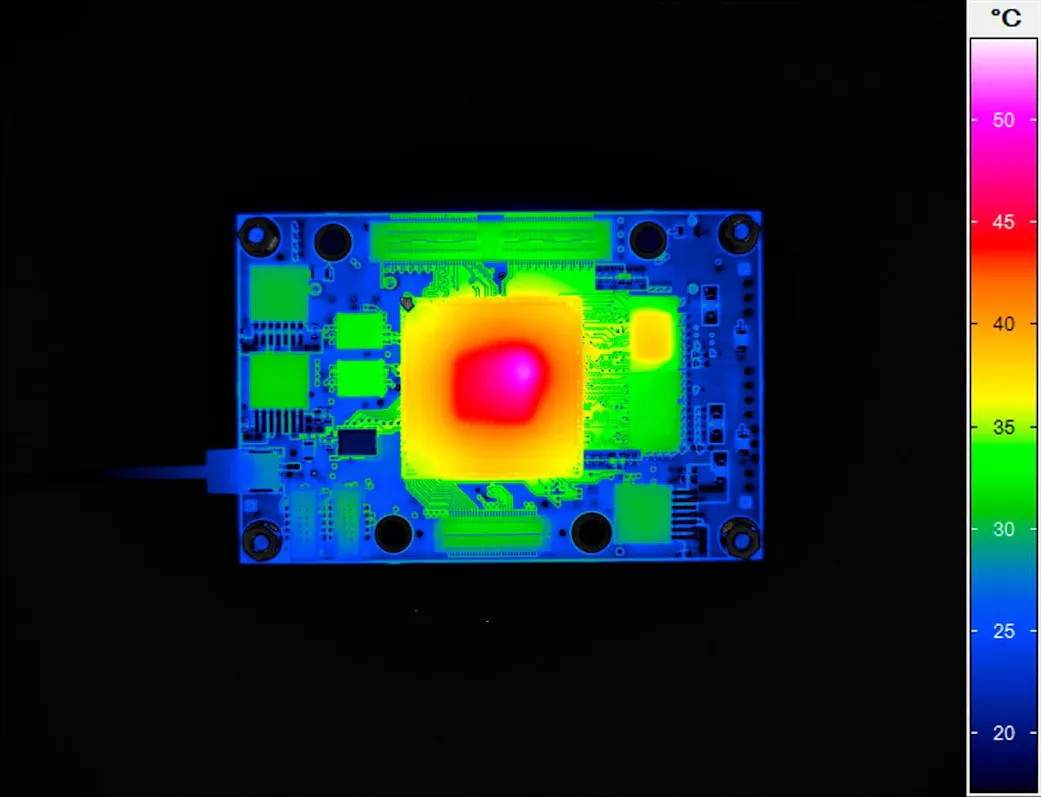

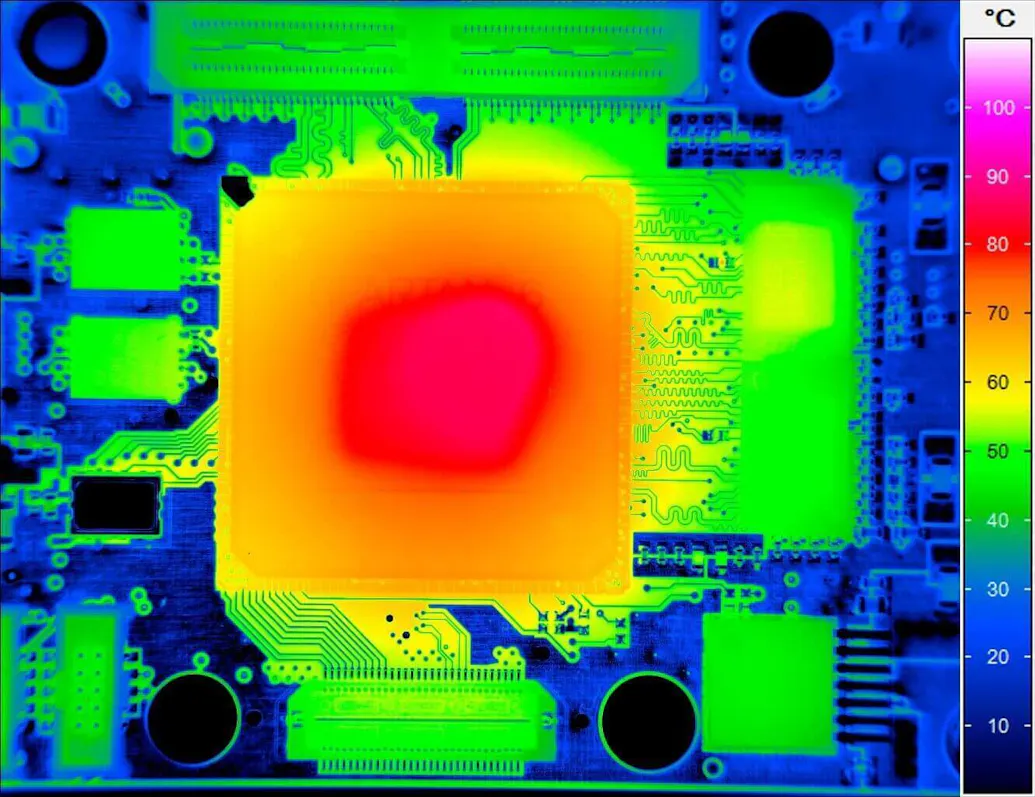

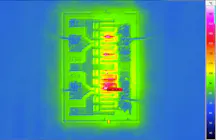

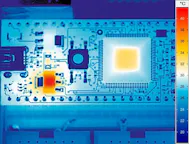

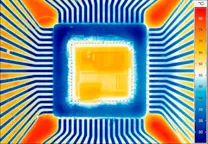

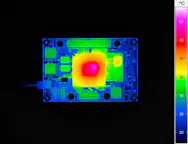

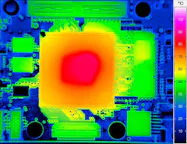

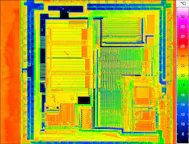

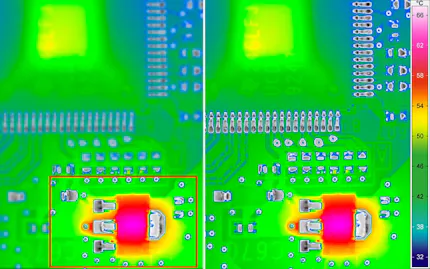

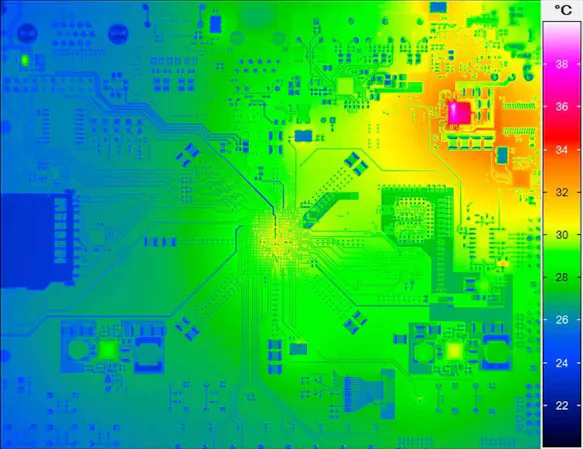

Hotspots and atypical temperature distributions on the surface of printed circuit boards, integrated circuits and multichip modules

Increased contact resistances

Increased resistance due to constriction of wires

Hidden cracks in joints

Power losses due to RF mismatch

Incorrect thermal connections of heat sinks

Short circuits, soldering defects such as cold solder joints

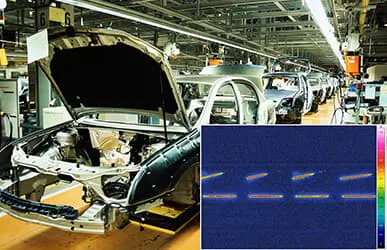

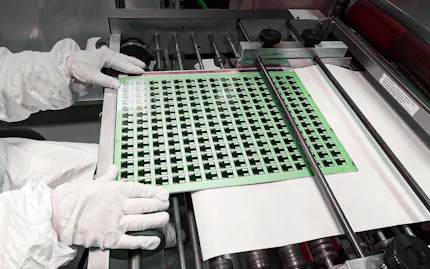

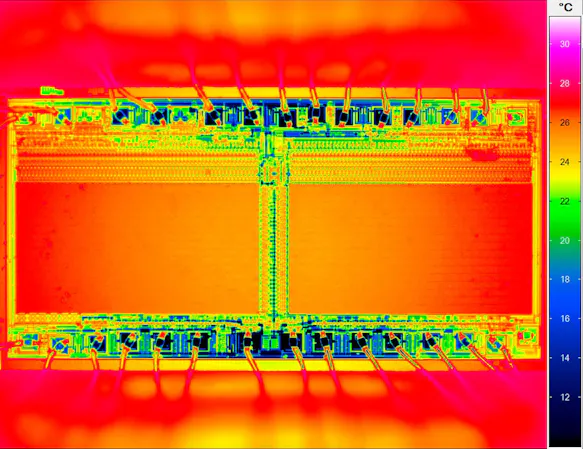

Thermographic analysis during each development step provides important conclusions for the optimisation of heat management and the design of complex electronic assemblies. In electronics production thermographic temperature measurement is used as a versatile instrument for quality assurance. High-performance thermography has become indispensable for setting critical technological parameters and their permanent monitoring as well as for inline testing of products in the production process and their final functional test.

Examples for Thermography in Electronics Applications

Infrared Lock-in Thermography for Inspection of Electronics and Integrated Circuits

Failure analysis and defect inspection, quality and process control and flexible R&D solution

Hotspot detection on printed circuit boards, integrated circuits, semiconductor material and multi-chip modules

Detection of faulty thermal connections of heat sinks, short circuits, soldering defects and wire bonding errors

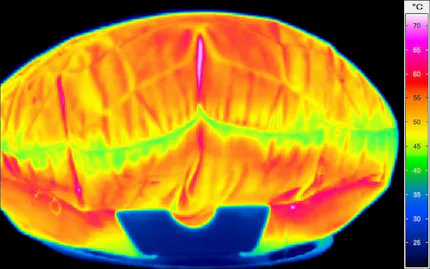

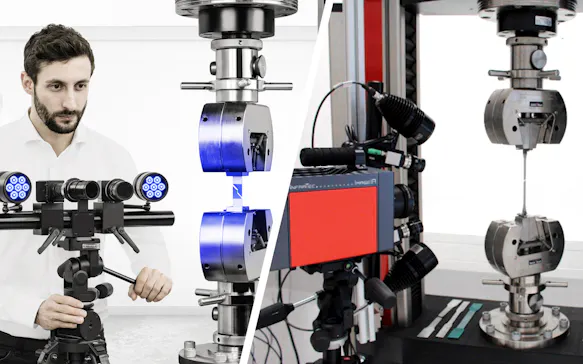

Thermography and Digital Image Correlation – A Winning Team in the Materials and Components Testing Field.

Active thermography for non-destructive testing

Synchronizing high-tech sensors: ZEISS/GOM ARAMIS and infrared cameras from InfraTec

Tracking of temperature on homologous points in 3D space

Applications in materials, components and electronic testing

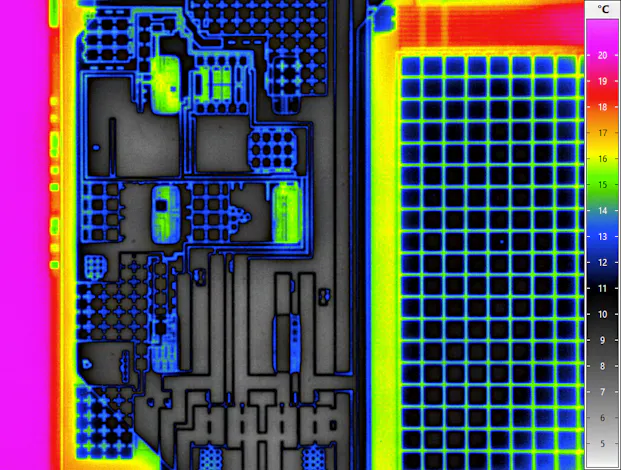

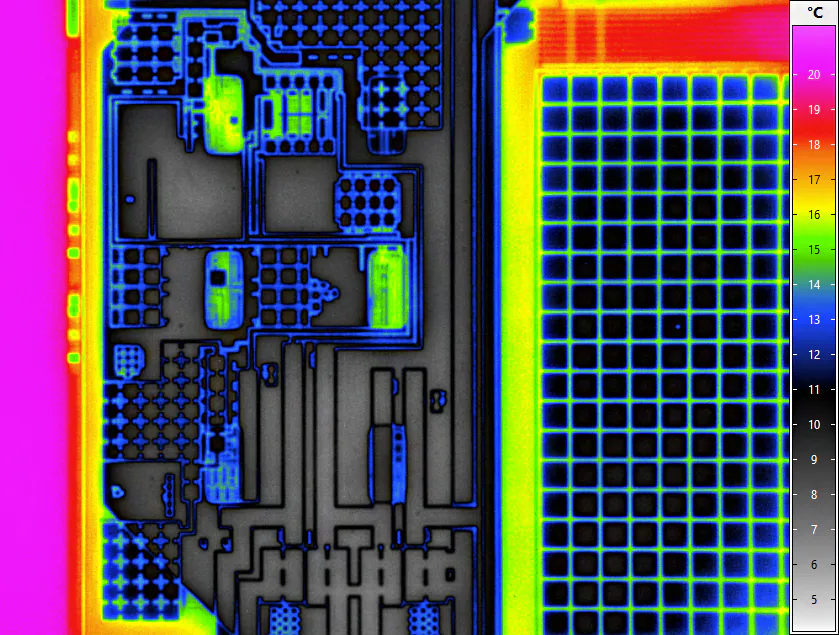

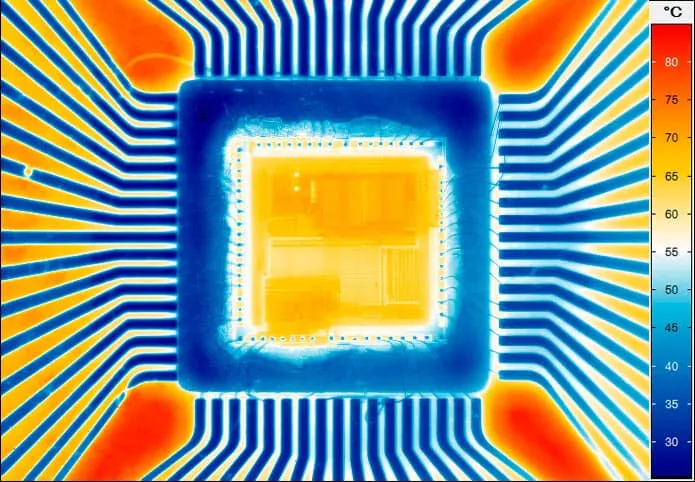

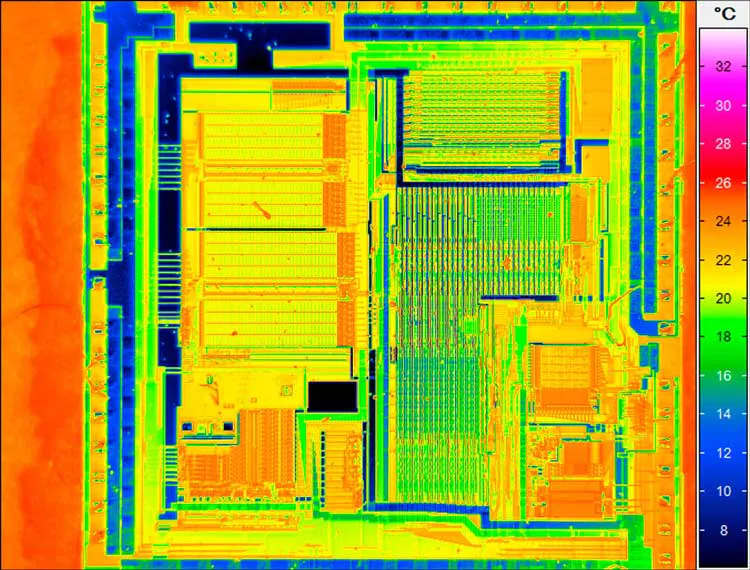

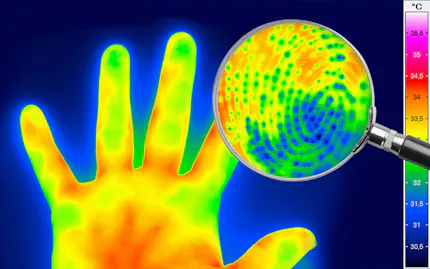

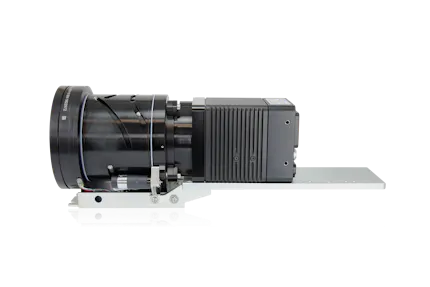

Micro-Thermography – Contactless Temperature Measurement in the Micrometer Scale

What are the physical characteristics of micro-thermography?

What are the technical requirements for an IR camera system?

Which selection criteria are important and relevant?

In which application areas is micro-thermography used?

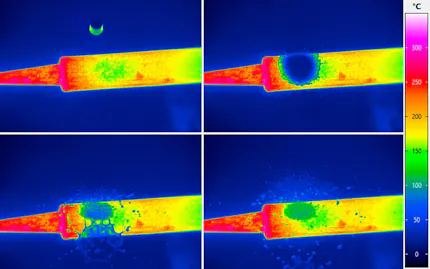

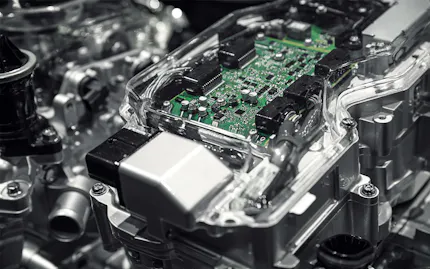

Thermography Solutions for Power Electronics – Precise, Non-contact and High-speed

Challenges of electronics testing

Improvement of electronics design and thermal management by understanding heat

Thermography in the various phases of electronics development and production

Important and relevant selection criteria

Further Characteristics of the Use of Thermography in Electrical Engineering and Electronics

Influences neither the RF impedance of the measurement object nor the heat dissipation of the same, which serves the safe avoidance of corresponding measurement errors

Allows safe temperature measurement even on live working parts

Complete recording of the temperature distribution and its temporal course of complex assemblies

Highest spatial resolution by using measurement systems with detectors with a very high number of pixels and opto-mechanical MicroScan unit

Resolution of smallest geometrical structures using close up lenses and infrared microscope lenses

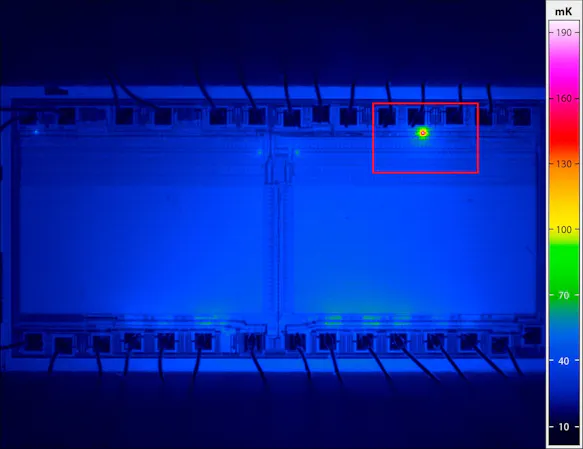

Detection of smallest temperature differences using cooled photon detectors and lock-in measurement methods

Easy-to-use analysis and documentation of measurement results with powerful analysis software

Advantages when Using Powerful Thermographic Systems

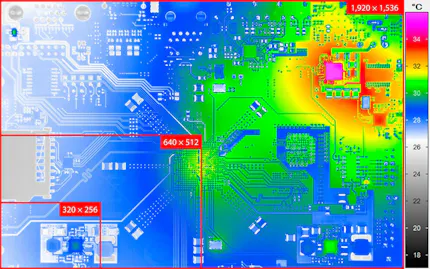

up to (1,920 × 1,536) native IR pixels for testing complex assemblies

with pixel sizes up to < 1 μm using specific microscopic lenses

between defective and intact structures in the range of a few micro-Kelvin due to high thermal resolution up to < 0.015 K in combination with the lock-in method

of up to ± 1 °C or 1 % for accurate measurement results

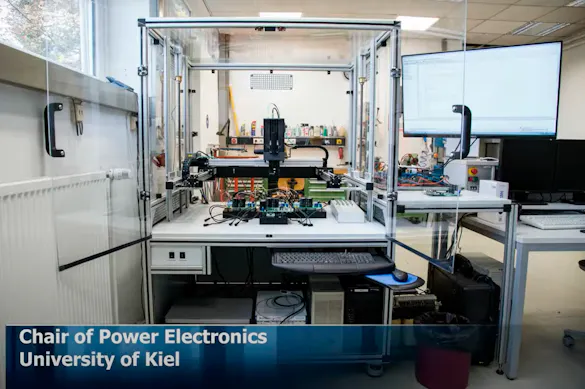

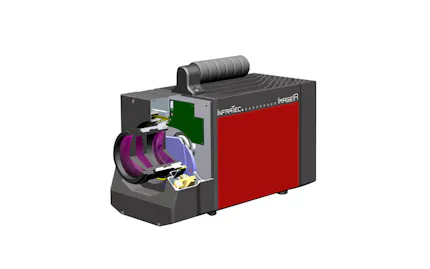

Individual Configuration of Thermographic Systems for Electronics and Electrical Engineering

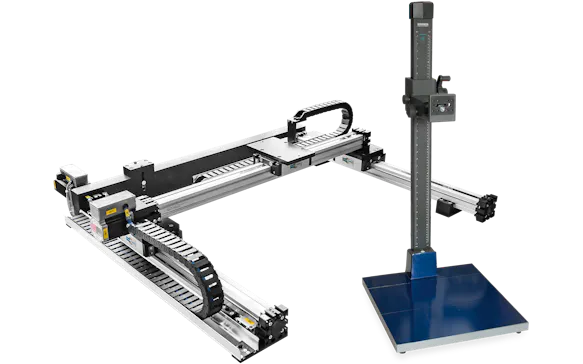

Depending on the respective task, users can get the equipment configured meeting their specific needs. The starting point will usually be the thermographic camera. Cooled or uncooled detector? Which detector format? Shall the thermographic system support lock-in thermography? How much flexibility is desired for the distance between the measurement object and the camera? What influence does this have on the choice of microscopic lenses and close-ups? Depending on what the answers to these questions will be, InfraTec can offer thermographic systems of various performance levels - from the individual camera to the automated modular E-LIT test bench.

Precise Localisation and Detailed Mapping of Hotspots and Temperature Differences

The principle of non-contact thermographic temperature measurement allows the error-free determination of the temperature of small objects with small heat capacity. This is often impossible, however, even when using the smallest contacting temperature sensors, as their heat dissipation frequently falsifies the measurement results. In many cases, the use of thermocouples is impossible due to the design or function of the circuit itself. In addition, the structures of electronic measurement objects are sometimes so small that temperature sensors cannot be attached to them.

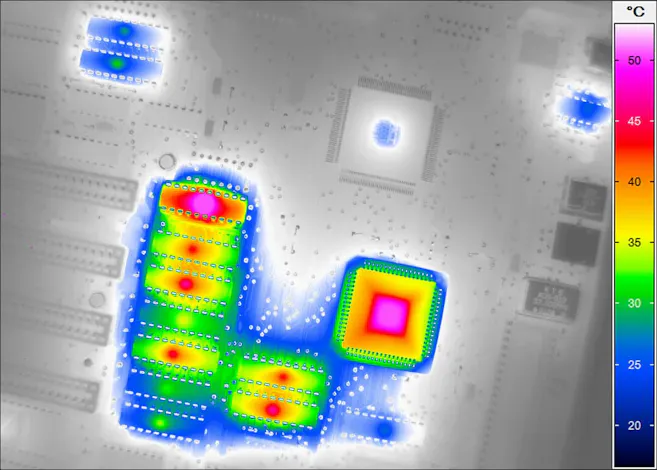

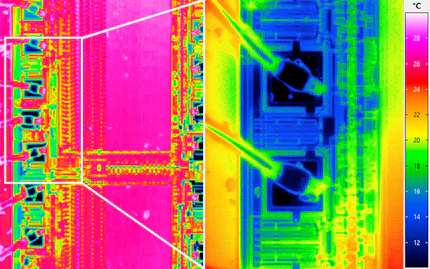

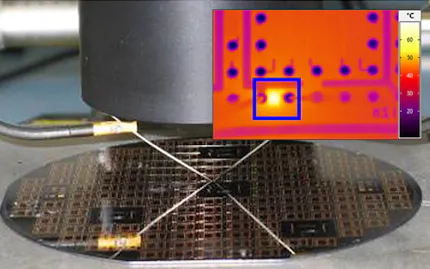

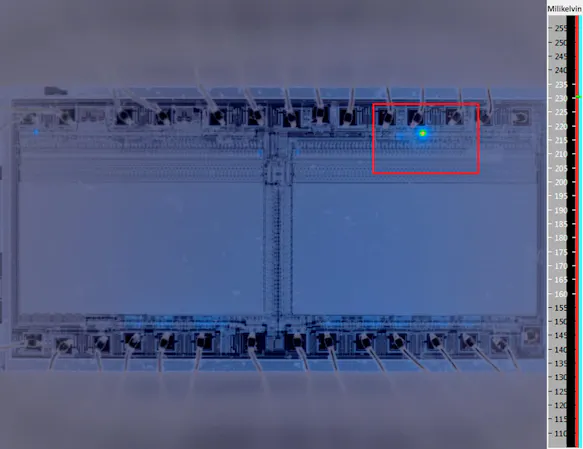

However, thermographic systems with a high spatial resolution are able to make such small structures clearly visible and, in addition, to determine their exact temperature distribution along with their chronological sequence. By means of specific close-ups and powerful infrared microscopic lenses, users can thermographically measure hotspots of just a few micrometres in size on the surface of components such as semiconductor components. If SIL lenses (Solid Immersion Lenses) are additionally used, even smaller structure sizes can be detected. In combination with appropriate active thermography methods (lock-in thermography), temperature differences of less than 1 mK are clearly visible for failure localisation.

InfraTec offers matching lenses and cameras with cooled and uncooled detectors with native resolutions up to (1,920 × 1,536) IR pixels. With MicroScan – available for cameras with both cooled and uncooled detectors - the spatial resolution can be further improved. The thermograms obtained in this way ensure that components and assemblies are depicted down to the smallest detail and that failures can be precisely detected and localised. Thermal images with an enormous spatial resolution of a few megapixels pay off especially for complex assemblies, where many structures can be captured simultaneously on the respective measurement and test object. If the pixel number of the detector of the used camera is too small, the number of images required for the complete acquisition of the measurement object increases.

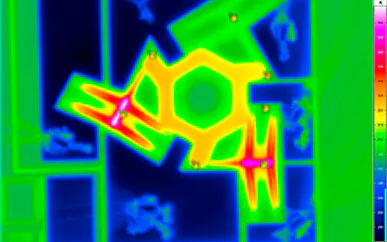

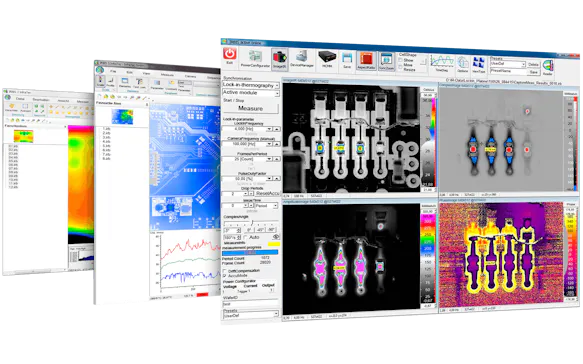

Lock-in Thermography in Electronics and Electrical Engineering

By means of lock-in analysis procedure of InfraTec's IRBIS® 3 active, errors that only cause mK or μK deviations can be reliably detected and assigned to their location:

Electronic Guide: Electronics / Electrical Engineering

Download our electronic guide “Electronics / Electrical Engineering” and get further information about thermography systems for use in development and production.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Clear Determination of only a Few Milli-Kelvin Temperature Differences

In general, thermography has now found a firm place in applications within electronics and electrical engineering. Reasons for this include the trend towards ever smaller, but at the same time more powerful components that are operated with ever lower supply voltages. Normally, lower electrical power consumption goes hand in hand with lower temperature changes from which any faults that may occur can be analysed. Infrared cameras with excellent thermal resolutions up to < 20 mK in real-time operation already fundamentally meet these requirements. However, this alone is not sufficient for certain measurement tasks. In addition, lock-in thermography will be required to detect slightest temperature differences. By means of periodic excitation, test objects can be examined non-destructively for defects and irregularities. The measurement time when using the lock-in method increases significantly with the desired resolution compared to a real-time measurement and can take several minutes. Therefore, it is particularly helpful if such measurements can be made "in one go" with a large-format camera providing high geometrical resolution.

A camera with a lower geometrical resolution, in contrast, forces the user to repeat measurements many times during the complete acquisition of the measurement object, especially if a failure cannot always be reliably reproduced. The money saved on purchasing a lower-cost camera then causes the developer to waste a lot of time on testing or production during the final inspection and can result in considerably higher costs.

Excellent Coordination of Infrared Camera, Thermography Software and Peripherals

InfraTec pays special attention to the optimal interaction between the thermographic camera and the software. Regarding the use in electronics manufacturing, the IRBIS® 3 thermography software offers a wide range of functions that support the use of passive and active thermography methods. These include, for example, the comparison between current thermal images and a reference image as well as the display of amplitudes and phase images with adjustable parameters for lock-in thermography. This allows the failure target to be reliably identified and clearly displayed.

The IRBIS® 3 also offers a tailored solution for thermographic measurements on printed circuit boards and hybrid assemblies. A great challenge with such measurement objects arises from the abundance of components used. These again consist of a variety of materials, such as different metals, ceramics and plastics, each with very different surface attributes.

For precise temperature measurement, the emissivity of the respective material at the surface is of particular importance. With the IRBIS® 3 software the emissivity for each individual pixel can both be determined and adjusted and so the measured temperature can automatically be corrected taking into account the emissivity and any reflected temperature. Various correction models are used for this and for taking into account other influencing factors, too. These models reproduce the respective measurement situation in such a way that all factors influencing the measurement result, such as radiation from the surroundings, windows used or damping properties of the measurement section, are taken into account. This allows the user to always achieve exact temperature measurement results if the relevant conditions are met.

Lenses

The extensive range of high-quality precision interchangeable lenses allows the field of view to be adapted to almost any measurement situation:

Wide angle, normal and telephoto lenses

Close-up attachments

Microscope lenses

Solid Immersion Lenses (SIL)

Accessories

Additional to the lenses, users can choose from a wide range of accessories:

Excitation controllers for active thermography

Two-axis positioning systems

X-Y measurement tables

Motorised microscope stands