Automatic Slag Detection in Steel Production - SLAG-DETECT

Non-contact slag detection with infrared thermography in steel production

Clear visual representation of tapping and deslagging processes through excellent image resolution

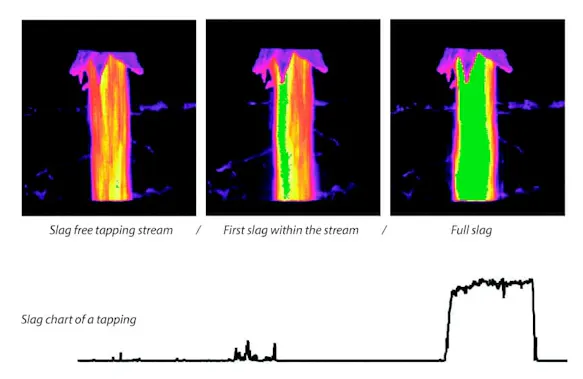

Precise distinction between steel and slag

Function for automated detection of the tapping end

Comprehensively adjustable data reposting on system PC or data server

Different variants of interfaces for the integration into process control system

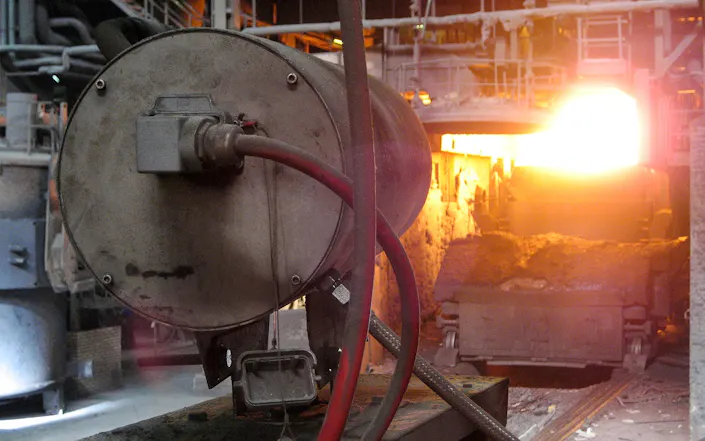

Slag Detection System with LW Infrared Camera for Highest Detection Reliability

Steel and slag in the process of steel production have different features with regard to radiation physics in the infrared spectral range. Thus, by means of an infrared camera, it is possible to determine without any contact and in real time which of both materials is the current main constituent of the tapping, respectively the deslagging stream coming out of the converter or an electric furnace. For this purpose, the relevant process of steel production is constantly monitored with an infared camera whose sensitivity range involves a long-wave infrared range of (8 ... 12) µm. In this wavelength range appears the highest contrast between steel and slag resulting in the best possible selectivity on material detection.

Suitable for Manual as well as Automatic Plant Operation

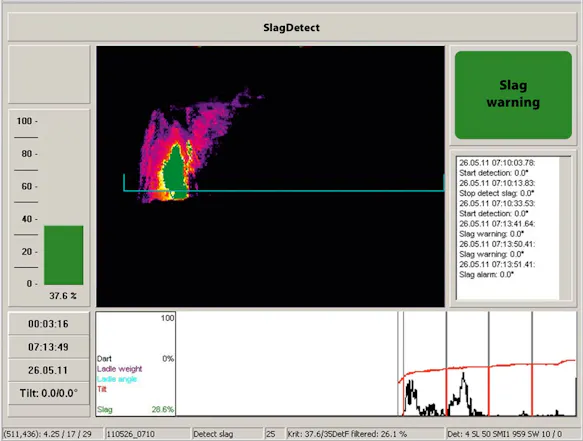

Independent of extended opportunities of an integrated automatic image evaluation, slag proportions in the VIS image will be highlighted in a different colour hue contrasting the rest of the infrared image (such as steel and image background). Thus, in case of manual operation, the smelter may detect slag parts due to the tapping's green colouring and is able to react according to technological specifications. Moreover, integrated evaluation algorithms provide an extended opportunity on an operator-independent reaction on automatically detected slag occurrence. In order to stop tapping immediately or at a specific delay time, a slag stopper, respectively the converter tilting backwards can be ensured via a direct signal to the process control system.

SLAG DETECT Software

Online calculation and monitoring (display) of slag amount

System alignment and adjustment to the process conditions

Decentralised monitoring of system status

Flexible process adoption, recording of tapping related process values and data exchange with existing systems via TCP/IP or electrical interface connection in the main cabinet

Reliable alarm release to activate a pneumatic slag stopper, filing of alarm screenshots, live tapping pictures of the whole tapping and process data arranged according to tapping time or heat number

Easy to operate data presentation via web interface – standard or professional package – in the steel plant network

Remote access available

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

SLAG-DETECT – Applicable for BOF Tapping Operation as well as EAF and Deslagging

Apart from its main application for BOF operation, using SLAG-DETECT can be very useful and advisable under other technological conditions of steel production. Thus, in many cases, it is possible to control the tapping at EAF systems (depending on their construction) with the help of infrared camera technology.In the same way, SLAG-DETECT has proved successful at numerous installations on tasks to be carried out in a reversed manner, the detection of steel during deslagging, and contributes to optimum material utilisation and high operational safety by avoiding the overstraining of the ladle's material. Being equipped with high-performance infrared camera technology adapted to harsh operating conditions in industry, SLAG-DETECT represents a reliable instrument ensuring product quality while making full use of the converter's capacity in the best possible way. Its flexible system configuration allows the integration into installations with different degrees of automation - starting from manual operation displaying the ongoing process in real time up to a fully automatic control of the converter's tilt angle during tapping.

Product Flyer

Get all the information you need at a glance in our product flyers