Applications & Industries

With more than 30 models, InfraTec offers a variety of infrared camera models for all application areas of thermal imaging. Please find your suitable infrared camera in the application areas, which are listed below.

InfraTec also expands its expertise in the field of thermography by participating in various research projects. Our partners are both national and international scientific institutions and companies from a wide range of industries.

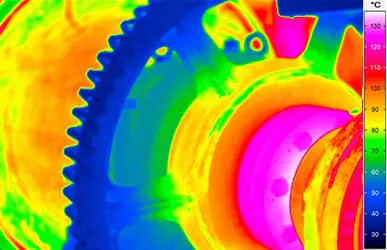

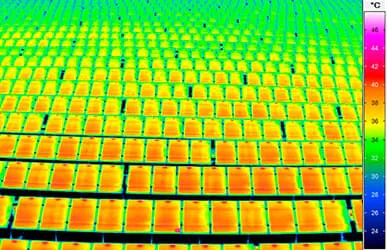

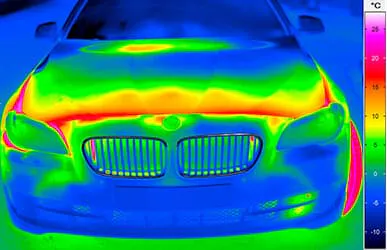

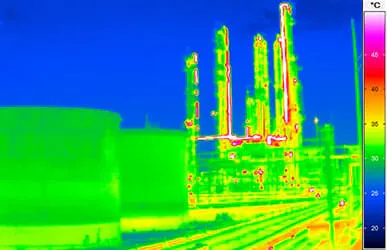

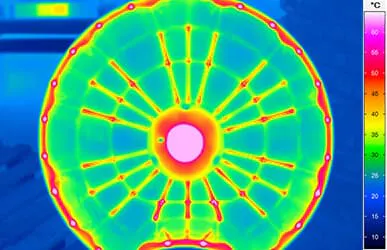

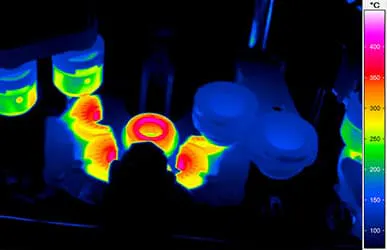

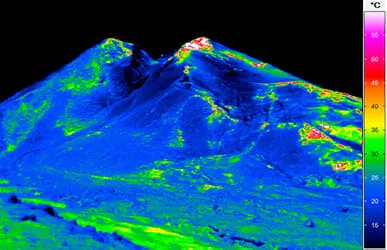

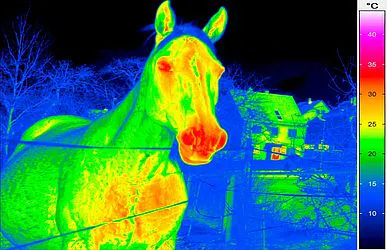

Application areas of thermal imaging

Industries of thermal imaging

Applications

Industries

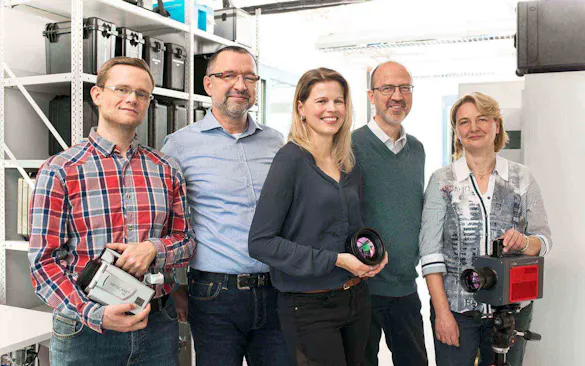

Statements of our Customers

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.