Spectral Infrared Thermography

Spectral thermography provides material specific precision measurements

Concentrate measurements on highly emissive or transmissive spectral ranges

Thermography on glass and through glass as well as temperature measurements through gases or even gas flames with spectral filters

Detection of various gases

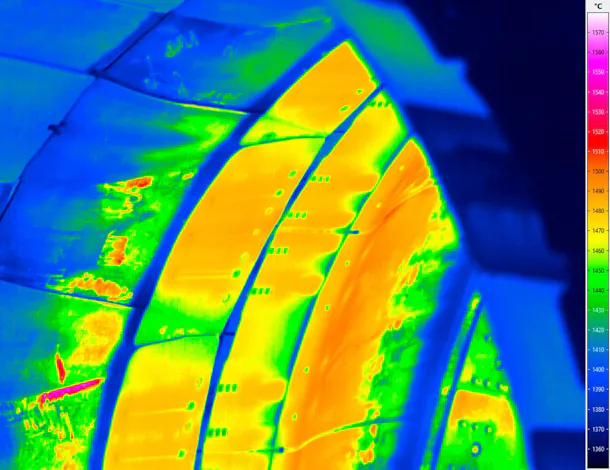

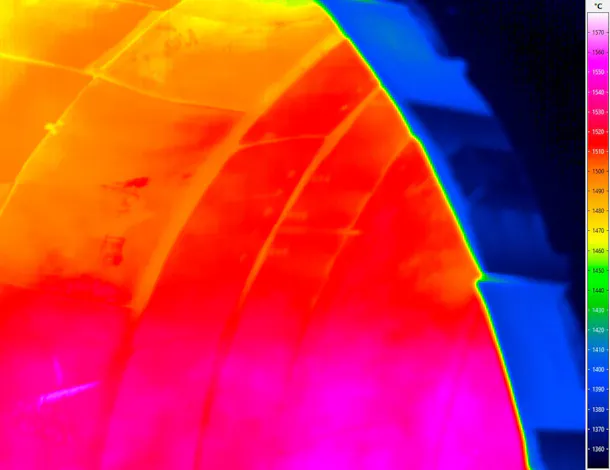

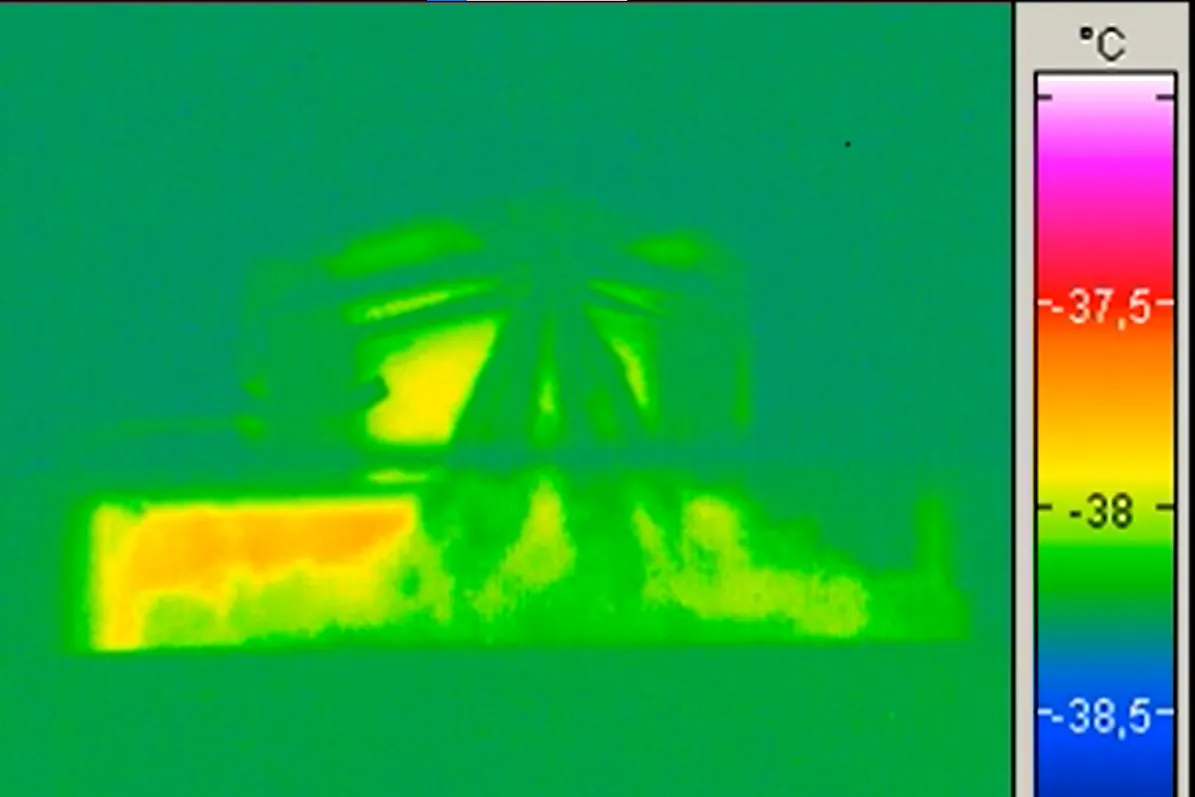

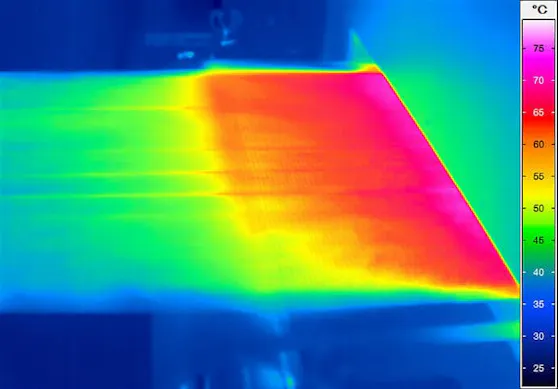

Recording of temperatures and characterization of large-scale flames

Filters close to the detector of the infrared camera avoid warm aperture effects

Measurement in Ranges with High Emissivity Reduce Measurement Error

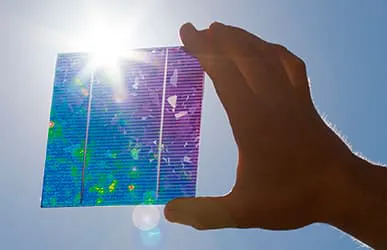

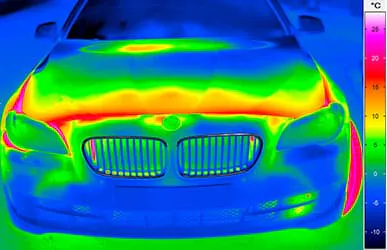

Emissivity values of materials greatly vary throughout the infrared spectrum. Concentrating the thermographic measurements on spectral ranges with an explicitly high or low emissivity can lead to detection of special effects. Spectral filters integrated in infrared camera systems allow the distinct transmission or blocking of radiation of selected IR ranges with the object’s high emissivity or high transmission. Thus, disturbing background radiation can be minimized and measurement errors reduced.

Users, who choose dedicated filter parameters, can e.g., measure and inspect the inside wall of a furnace whilst the burning gas is not detected due to the used filter – a typical measurement through gas. Another setting of the filter parameters can reduce the effect of the background radiation when measuring thin plastic foils to really measure the foil temperature itself.

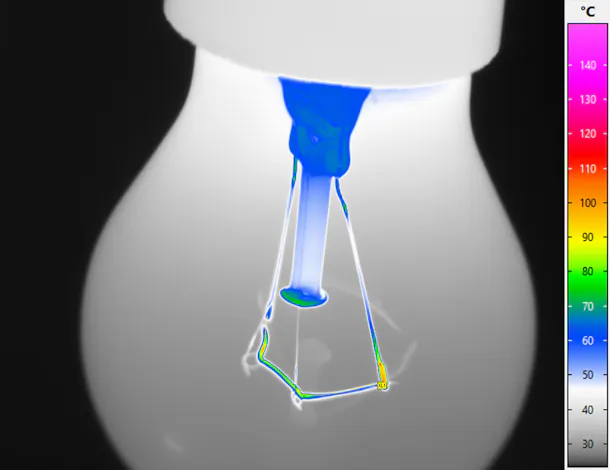

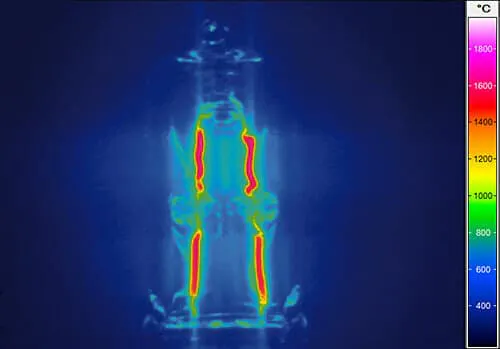

Measurement of Ranges with High Transmission

Concentrating on spectral ranges at which the transmission of the material is especially high allow for doing thermographic measurements of objects behind the material. The filament of a lamp can be measured without being influenced by the manifold colder glass of the lamp. The same holds true measuring objects behind flames.

Spectral Thermography – Basics and Applications

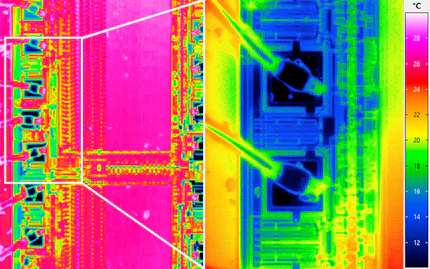

Thermography Solutions for Power Electronics – Precise, Non-contact and High-speed

General information about infrared thermography and InfraTec

Definition of spectral thermography

Advantages and challenges of spectral thermography

Examples of applications

Specific camera system requirements for spectral thermography

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

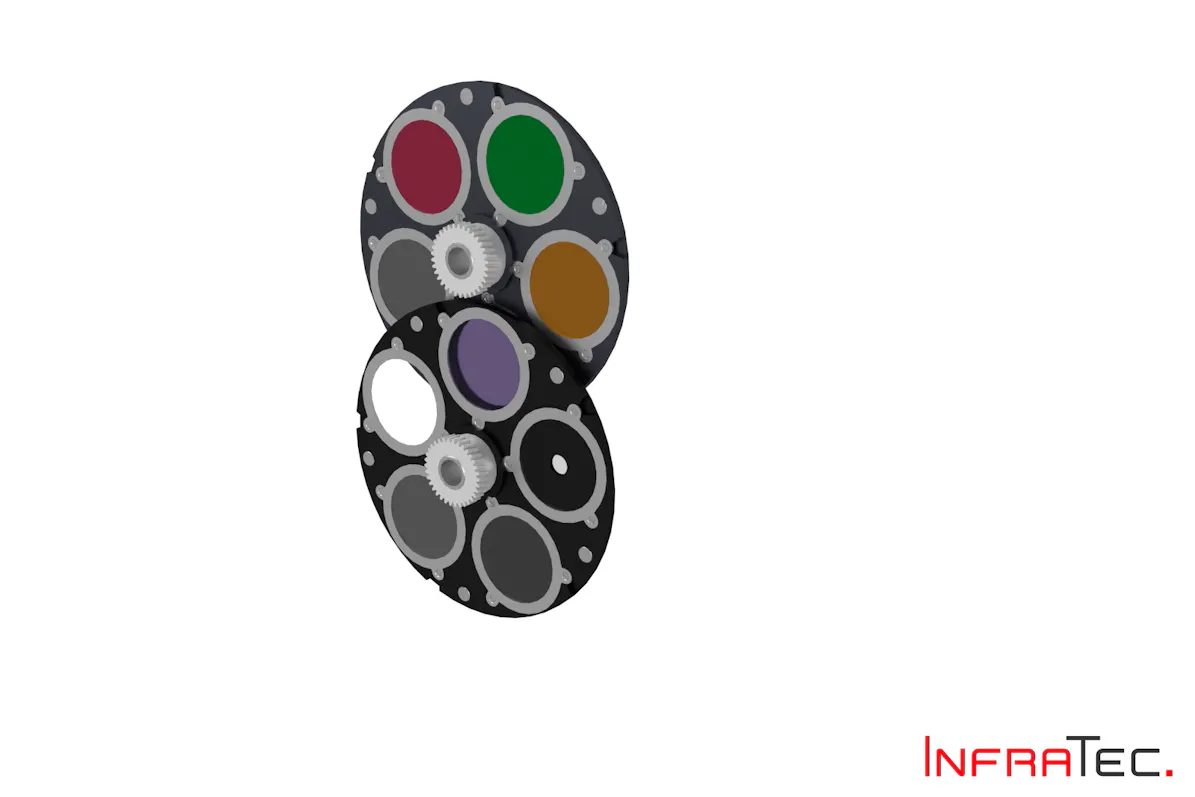

Wide Range of Spectral Filters for Mounting Close to the Detector

InfraTec offers a wide range of special spectral filters for thermographic measurement of the most different materials and applications. Those filters can also be customized. Both the infared camera systems of the ImageIR ® series as well as the long-wave uncooled VarioCAM ® hr head cameras provide facilities for a mounting close to the detector within a filter wheel or a filter slider. The filter wheel of the ImageIR ® models is especially convenient as filters can be changed remotely controlled and motorized. Warm aperture effects caused by a filter position in front of the lens and resulting in possibly big measurement errors can be avoided by such positioning close to the detector being possible in infrared camera systems of InfraTec.

Applications of Spectral Thermography

Besides the "on-glass" and "through-glass" measurement exists a number of other applications in different industrial sectors as well as in the field of research and development:

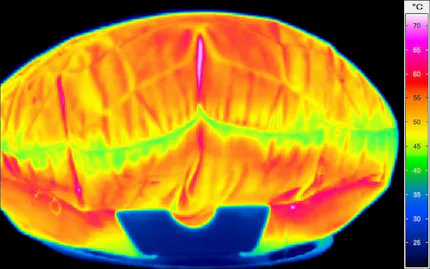

IR-reflectography

IR-reflectography is used for the detection of lower painting layers due to its spectral behaviour (upper layer transmissive, lower drawings reflective).Humidity detection

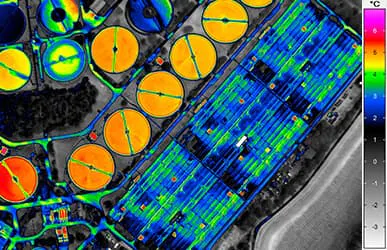

With the help of humidity detection, for example for the analysis of building materials in case of claims, the spectral absorption factor of water band is defined.Leakage

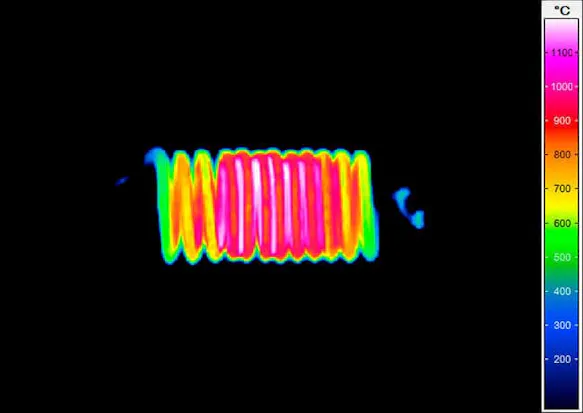

Another interesting application is the detection of leakages on tanks using IR-detectable gases. A suitable and available gas is CO2 , having a strong absorption band at 4,25 μm. A tempered background helps to recognize the leaving gas flow.Temperature measurement of flames

Temperature of flames can be estimated by measuring selectively within the absorption band of CO2 at 4.25 μm. Thermography at objects behind the flame is possible using the spectral range of (3.75 … 4) μm (for example furnace walls or pipes).Film extrusion process

IR-reflectography is used for the detection of lower painting layers due to its spectral behaviour (upper layer transmissive, lower drawings reflective).