Case Studies and Customer References

Well-known companies from all industries worldwide rely on the products of InfraTec. Thereby, the fields of application in infrared measurement technology as well as in sensor technology are numerous and often special. The following case studies will give you an insight into the various application possibilities of our products.

Use of Pyroelectric Detectors in Practice

One advantage of pyroelectric detectors is the versatility of their applications. Detecting and analyzing gases and gas mixtures, investigating the material composition of organic and inorganic compounds, monitoring flames – all this is of great importance in a wide range of industries. Selected examples will help you to get to know some of the possible applications and, at best, to gain valuable ideas for solving your own measurement and testing tasks.

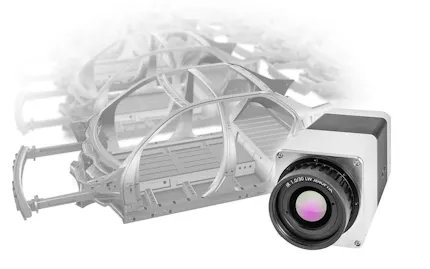

Use of Thermography Systems in Practice

Well-known companies from all over the world use infrared thermography as a measurement method in the development of new products, temperature-controlled process automation and quality control. Universities, technical colleges and institutes use thermography systems from InfraTec for applications in science and education. The spectrum of reports in which our customers describe the concrete use of their cameras is correspondingly broad.

Overview about Case Studies from Sensor Division

![Fig. 2: Working principle of the measurement devices (© LiORA) Working principle of the LiORA measurement devices]()

Accelerated Remediation of Contaminated Sites

Remediating sites contaminated with pollutants takes a long time. The Canadian company LiORA offers measurement devices that can help to reduce the remediation time from 20 years to two. This is accomplished by combining the latest detector technology from InfraTec with AI-controlled analysis. LiORA is revolutionizing the way companies can monitor and manage contaminated sites. Remediation projects can be completed faster, budget costs are reduced, and soil quality is improved worldwide.

Read more about LRM-284 detector in LiORA measurement devices![Shenzhen Prior-Care Science Technology analysers for anaesthetic gases using InfraTec detectos. analysers for anaesthetic gases]()

Reliable Detectors for Medical Gas Analysis

The Chinese company Shenzhen Prior-Care Science Technology (Prior-Care) manufactures analysers for anaesthetic gases as well as other medical products. The accurate, continuous real-time measurement of the concentrations of inhaled and exhaled gases is vital for patients during surgery. That is why Prior-Care only uses highly reliable detectors in its analyzers. An InfraTec detector (LRM-284) was selected for two devices due to its high stability and consistency.

Read more about 4-channel detector LRM-284 in analysers for anaesthetic gases![Detection of unknown gases with Xplorir from RedWave Detection of unknown gases with Xplorir from RedWave | Picture credits: @ RedWave Technology]()

The Chemical Threats Detective

RedWave Technologies builds products to protect communities and countries from accidental and intentional chemical threats. The handheld and portable FTIR spectrometers from RedWave with integrated pyroelectric detectors from InfraTec are used to identify unknown chemicals by safety professionals and emergency response personnel. Unknown chemical spills and releases can come from transportation accidents, industrial accidents, residential and industrial fires, or other catastrophic events.

Read more about hazardous substance analysis with pyroelectric detectors![Patient being tested on Vyaire's Vyntus™ CPX Metabolic Cart. Patient being tested on Vyaire's Vyntus™ CPX Metabolic Cart.]()

Pyroelectric Detectors in Pulmonary Diagnostics

Vyaire Medical develops devices for the diagnosis, treatment, and monitoring of respiratory diseases. Alongside our other products, we can provide a spiroergometric system for lung function diagnostics, such as the VyntusTM CPX. Integrated into the VyntusTM CPX is the pyroelectric detector LMM-242 from InfraTec.

Read more about the pyroelectric detectors for pulmonary diagnostics![Analytical instrument ERASPEC from eralytics in use Analytical instrument ERASPEC from eralytics in use]()

Special Detector for Fuel Analysis

Since 2007, the eralytics company has been developing and manufacturing analytical instruments for quality control in the mineral oil as well as the flavor and fragrance industry. One of the multi-fuel analyzers is ERASPEC. It allows the measurement of different properties of fuels. ERASPEC is equipped with a pyroelectric detector from InfraTec - the special detector LIE-312.

Read more about the special detector for fuel analysis![Mobile methane measurement device IRwin® with pyroelectric detector LIM-262 from InfraTec Mobile methane measurement device IRwin® with pyroelectric detector LIM-262 from InfraTec]()

Leak Detective in Action for More Safety

The INFICON company develops and produces, among other things, gas detection and concentration measurement devices. The IRwin® portable natural gas detector is one of them. A product for use in gas pipelines leak detection survey, commissioning and emergency, as well as for Landfill Surface Emission Monitoring. On board: a pyroelectric detector from InfraTec.

Read more about leak detection with the help of pyroelectric detectors![Gas sensor LY-NDIR by Haina including InfraTec detector LRM-284 Gas sensor LY-NDIR by Haina including InfraTec detector LRM-284]()

InfraTec Detectors against Global Warming

Qingdao Laoying Haina Group uses infrared detectors to equip its self-developed devices for environmental gas analysis.

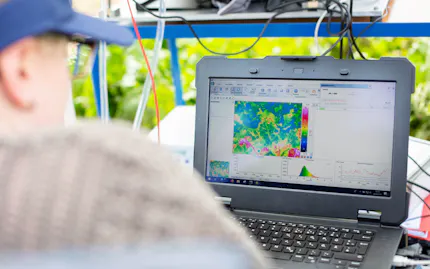

Read more about gas sensors for environmental gas analysis![Measurement of photosynthesis in the field Measurement of photosynthesis in the field]()

Feeding the World

Studying plants to improve crop performance and yield. The global population is growing and current crop yield is not keeping up with this pace of growth.

Measurement of photosynthesis in the field![InfraTec Sensor Division - Helicobacter InfraTec Sensor Division - Helicobacter - Picture credits: © iStock.com / 482337236]()

Take a Deep Breath

Half of the world‘s population is infected with the bacterium Helicobacter pylori. Thanks to Beijing Richen-Force Science & Technology, Helicobacter pylori can now be reliably detected.

Read more about bacterium Helicobacter pylori![InfraTec Sensor Division - Measuring the breath alcohol concentration InfraTec Sensor Division - Measuring the breath alcohol concentration]()

A New Generation for Measuring Breath Alcohol

Alcohol is the most frequent cause of death in road traffic accidents and 20% of work-related accidents are caused by alcohol. According to the WHO, about three million people die worldwide each year from alcohol consumption – that is more than from AIDS, violence and road accidents combined.

Read more about the new generation for measuring breath alcohol![InfraTec Sensor Division - Asclepion Laser InfraTec Sensor Division - Asclepion Laser - Picture credits: © iStock.com / 1132827504 enes evren]()

Scars Fade Thanks to Laser Treatment

Diseases such as chickenpox and acne leave scars that can affect a person for a lifetime. Thanks to dermatological lasers, these can be removed gently and safely without anaesthesia or just with local anaesthetic, even from the face.

Read more about about scars fade thanks to laser treatment![Cannabis Analyzer supports analysis of medically relevant substances of cannabis Cannabis Analyzer supports analysis of medically relevant substances of cannabis]()

Smells Like Medicine

Cannabis serves as a basis for oils, fragrances, clothing, intoxicants – and as a medicine. Already several thousand years ago the Chinese used it as a remedy against rheumatism. Nowadays, researchers worldwide are again dealing with the medical use of the plant. Infrared sensors provide answers to the question of which type contains which active ingredients.

Read more about cannabis analysis![Prototype for respiratory gas analysis of Geratherm Respiratory GmbH’ Prototype for respiratory gas analysis of Geratherm Respiratory GmbH’]()

Health Care in One Breath

„Please strip to the waist.“ Medical examinations still frequently begin with this sentence. Still. This sentence could very soon be: „Please breathe out strongly.“ For research in the field of respiratory gas measurement systems are making considerable progress. The aim is clear: To make the diagnosis of illnesses easier and painless.

Read more about health care![Awite’s non-dispersive multi-gas sensor is suitable for biogas analysis due to lower drift rates and improved transverse sensitivity to other hydrocarbons Awite’s non-dispersive multi-gas sensor is suitable for biogas analysis due to lower drift rates and improved transverse sensitivity to other hydrocarbons]()

Energy Miracle with Natural DNA

What does your breakfast egg from the weekend, a cornfield and a large portion of french fries from a fast-food restaurant have in common? They all provide raw materials for a biogas plant. Organic substances such as egg shells, corn or potato peelings are decomposed there naturally under airtight sealing. The result is an energy-rich and extremely versatile product – biogas.

Read more about biogas analysis

Overview about Case Studies from Measurement Division

![Infrared camera ImageIR® 8300 hp Series from InfraTec Infrared camera ImageIR® 8300 hp Series from InfraTec]()

Tracing the Solar System´s Origin via Microscopic Active Thermography

Geological field research is an easy task on Earth – you literally stand on your samples. But terrestrial material has a significant drawback for those who are searching for pristine samples from the earliest days of our Solar System – it has been altered many times. Those who want to utilize pristine samples have to go beyond our atmosphere into deeper space – where planetoids carry it since the early days of our Solar System. Using microscopic active thermography, Japanese researchers were able to confirm that the minor planet Ryugu bears original material from the early days of our Solar System.

Read more about the use of ImageIR® 8300 for anlysing the Ryugu probes![infrared camera at 3d printer infrared camera at 3d printer]()

3D Printing under the Thermographic Microscope

Additive manufacturing has developed rapidly from its original field of prototype manufacturing, becoming a complete production technology for use on an industrial scale. Precise monitoring of machinery, equipment, materials and – above all – temperatures is of vital importance in this regard.

Get further information about thermography in additive manufacturing![At the geographic south pole At the geographic south pole]()

Antarctic Building Thermography

Building thermography is a popular and established application for thermal cameras. Today the related services are frequently provided with simple “pistol” style cameras and from low-cost service providers. But when it comes to perform precision thermography you definitely need serious equipment and professional users!

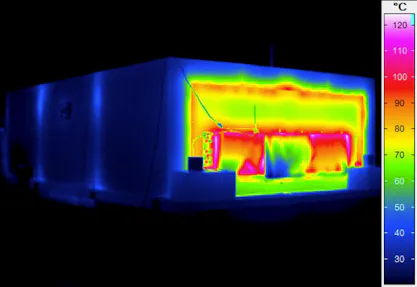

Get further information about building thermography![Thermal imaging of a shrink tunnel prototype Thermal imaging of a shrink tunnel prototype]()

Thermal Imaging in Plastics Engineering

A core topic of modern materials research is the research on plastics as a versatile material for various technological applications. Quite often, industrial applications are developed from academic basic research.

At the Faculty of Mechanical Engineering at the University of Paderborn, Kunststofftechnik Paderborn (KTP) works intensively on this topic using a VarioCAM® HD for this purpose.

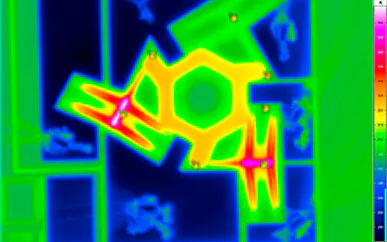

Get further information about thermography in material research![BTU Cottbus - Failure Analysis on Electronic Components | InfraTec Failure Analysis on Electronic Components | ©BTU Cottbus-Senftenberg]()

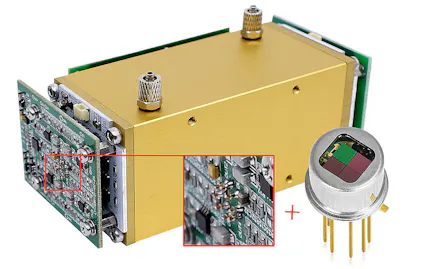

Thermography on the Trail of the Fault

Today, thermographic damage and function analysis of electronic components is an established test method in electrical engineering. This method is also used for research purposes at the Institute for Electrical Systems and Energy Logistics at BTU Cottbus-Senftenberg. In this context, Prof. Dr. Ralph Schacht is intensively involved with the material and system characterisation as well as the non-destructive failure analysis of printed circuit boards, electronic components, microelectronics as well as composite systems of packaging and interconnection technology.

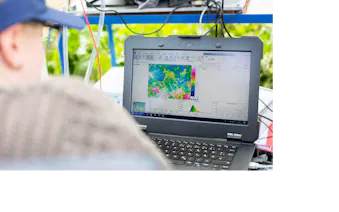

Read more about non-destructive failure analysis on electronic components![InfraTec & KWS Saat - Thermography in Plant Research InfraTec & KWS Saat - Thermography in Plant Research ©KWS SAAT SE & Co. KGaA]()

The Seeds of the Future

Environmental conditions today often tend towards extremes. Many areas are very humid and wet, while others are predominantly dry. Particularly in the second case, cultivating raw materials such as grain, beet or maize is a challenge. A challenge that KWS SAAT SE & Co. KGaA is facing. As part of its plant research, the company uses the VarioCAM® HD head 900 infrared camera from InfraTec to analyse the behaviour of plants during drought stress and pest infestation.

Read more about thermography in plant research![InfraTec & Highland Helicopters - Aerial Fire Mapping InfraTec & Highland Helicopters - Aerial Fire Mapping ©Highland Helicopters Dunedin, New Zealand]()

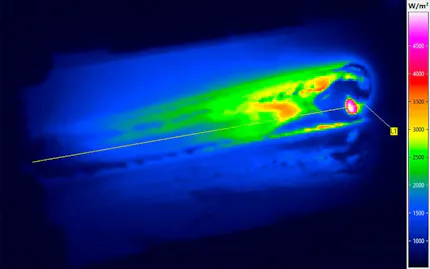

Catching Fire – Aerial Fire Mapping

Wildfires are a permanent threat for several regions around the world – and the global climate change is adding to the number and severity of these events. Fighting them is a huge challenge, strong winds, heat and inaccessibility make it even more difficult and dangerous for those who risk their life to protect others. One approach to tackle wildfires is the usage of airborne fire mapping.

Read more about aerial firemapping![InfraTec thermography casestudy tu chemnitz InfraTec thermography casestudy tu chemnitz]()

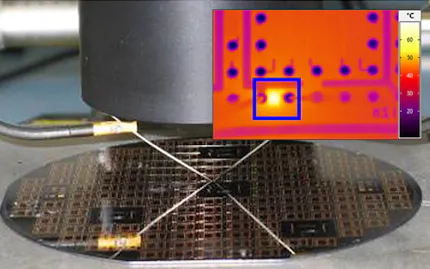

Thermal Micro Actuators for Nanotechnologies

Microelectromechanical systems (MEMS) offer a wide range of possible applications in the field of nanotechnology. Everyday examples are the position recognition of mobile phones and the use in airbags, digital cameras or pacemakers. Other applications can be found above all in the field of miniaturised medical diagnostics. Growing demands on miniaturisation affect both the system solutions required for this and the sensors and control elements to be developed.

Read more about thermography in nanotechnologies![InfraTec Thermography Success Story: CAU Kiel InfraTec Thermography Success Story: CAU Kiel]()

Power Electronics – Efficient Control of the Futures Energy

The energy efficiency of electronic components is becoming increasingly important in numerous fields of application. And that is not all: in our electronic and high-tech age, the demand is for even faster active components, higher power densities of miniaturised systems as well as absolute reliability. Along with this, there is the request for environmentally conscious resource procurement and the requirement that the increase in performance of modules should run parallel to lower energy consumption.

Get further information about thermography for power electronics![InfraTec WUN Bioenergie Woodpelletstorage InfraTec WUN Bioenergie Woodpelletstorage]()

Fire Protection in Wood Pellet Storage

Wood pellets as an alternative and high-quality fuel have become increasingly important in recent years. Their local origin from sustainable cultivation in the region has given WUN Bioenergie GmbH the opportunity to respond to market demand as an environmentally friendly supplier of raw materials. However, like other fuels, stored wood pellets need to be secured and monitored around the clock to prevent causes of devastating damage in the event of a fire, for example. Robust and reliable thermography solutions are a suitable tool for plant protection here.

Get further information about the FIRE-SCAN Monitoring System![InfraTec - WASTE-SCAN ARC Copenhagen InfraTec - WASTE-SCAN ARC Copenhagen - © ARC amager ressource center]()

Early Fire Detection in Incineration Plant

The Amager Resource Center (ARC) is a waste incinerator like no other. From the roof of the Waste to Energy facility, skiers and snowboarders wind their way down on green plastic mats from a height of about 80 meters, even in the summer. The city hall of the Danish capital, Copenhagen, is just five kilometres away. The location, which is almost in the heart of a European capital, as well as its use as a public leisure centre, shows how much confidence operators place in the safety of the ARC. An important component in the security concept is the WASTE-SCAN infrared monitoring system for early fire detection by InfraTec.

Get further information about WASTE-SCAN Monitoring System for safety in Waste-to-Energy Plant![InfraTec - Process Monitoring During Open‐die Forging InfraTec - Process Monitoring During Open‐die Forging]()

Process Monitoring During Open‐die Forging

Anyone who wants to produce curved or twisted steel and aluminium components, can rely on bending forging nowadays. Components with complex geometries can now be manufactured by means of this incremental forging variant.

Get further information about VarioCAM® HD head 800 for process monitoring during open‐die forging![InfraTec ZMS Müllkraftwerk Schwandorf Twin System Waste Bunker InfraTec ZMS Müllkraftwerk Schwandorf Twin System Waste Bunker]()

WASTE-SCAN Against “Black Clouds”

Many tons of waste are bunkered and processed every day in waste recycling plants. It is not uncommon for this to contain highly flammable materials. If ignition sources get into this storage area, for example during delivery, there is an acute risk of fire. Therefore, waste incineration plants are subject to the strictest fire protection requirements in order to prevent endangering the environment and local residents. For this reason, an extremely important preventive measure is the permanent monitoring of the waste bunker and, if necessary, the surrounding areas.

Get further information about WASTE-SCAN Monitoring System for safety in plant operation![Monitoring the Surface Temperature on Curing Epoxy Resin Samples Monitoring the Surface Temperature on Curing Epoxy Resin Samples - Picture credits: © AdobeStock / wichientep]()

Monitoring the Surface Temperature on Curing Epoxy Resin Samples

Epoxy resin systems are mostly used as a matrix material in fibre composites. In a variety of manufacturing processes, the corresponding resin system is processed in a flowable state. The material only acquires its rigidity in a subsequent curing process. This is characterized by an exothermic chemical reaction with a pronounced temperature dependence.

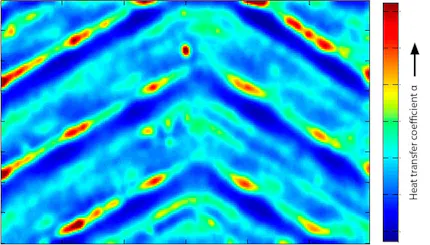

Get further information about curing epoxy resin samples with VarioCAM® HD research 800![Determining heat transfer coefficients at Leibniz University Hannover Determining heat transfer coefficients at Leibniz University Hannover]()

Infrared Thermography for Determining Heat Transfer Coefficients

Technical systems and devices are often subject to the influence of thermal energy or heat up due to internal processes. Their efficiency and service life can be increased, for example, by optimised thermal management. The installed active components are usually optimised extensively for this purpose. Passive components, on the other hand, are often neglected in this respect.

Get further information about ImageIR® 8300 for determining heat transfer coefficients![InfraTec Uni Bayreuth - Analysis of the Thermal Conductivity InfraTec Uni Bayreuth - Analysis of the Thermal Conductivity]()

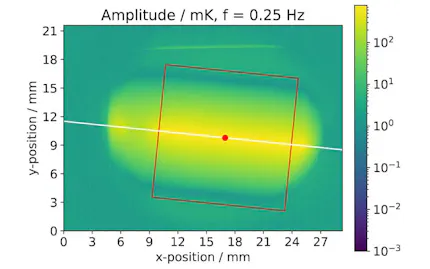

Analysis of the Thermal Conductivity in Nano- and Mesostructured Polymer Systems

New materials with precisely controlled optical and thermal transport characteristics can make a large contribution to resource-saving thermal management. Scientists of the University of Bayreuth are pursuing this vision. They use infrared thermography to quantitatively determine thermal conductivity in nano- and mesostructured polymer materials.

Get further information about Lock-in Thermography with VarioCAM® HD research 800![Inline Process Control for Quality Assurance of Weld Seams - TU Ilmenau Inline Process Control for Quality Assurance of Weld Seams - TU Ilmenau]()

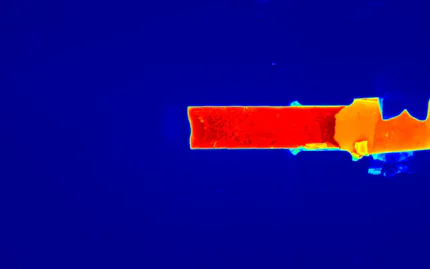

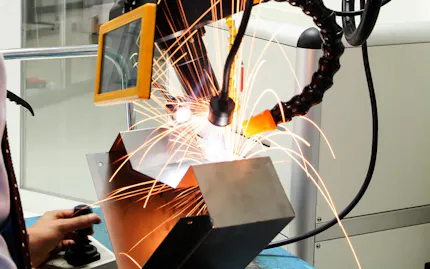

Inline Process Control for Quality Assurance of Weld Seams

As part of the 3dStahl collaborative project, a 6-axis robot, equipped with a welding machine, was attached upside down to a wall-to-wall wire rope hoist kinematics system in order to automate joining processes involving small quantities or even individual parts such as large-scale objects (lock gates, bridges).

Get further information about continuous process quality assurance using an infrared camera![Inspection of district heating pipelines using thermography Inspection of district heating pipelines using thermography]()

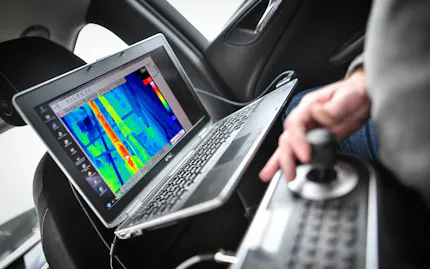

Inspection of District Heating Pipelines

District heating is generally regarded as an extremely efficient and environmentally friendly form of energy supply. Based on industrial waste heat or renewable energy sources, it offers the possibility of heating water and thus supplying private, commercial and industrial customers. Netze Duisburg GmbH is doing to control the city's entire district heating network supported by InfraTec infrared cameras.

Read more![Hochschule Aalen - Laser soldering Hochschule Aalen - Laser soldering]()

Laser High-temperature Capillary Gap Brazing

Lasers are extremely versatile tools in industry and manufacturing technology. Due to their flexibility, they serve as a key technology for implementing the goals of industry 4.0. Although laser cutting and welding are nowadays regarded as turnkey technologies, the majority of laser applications, for example joining of hybrid materials, 3D printing or ultra-short pulse processing, still require considerable research and development.

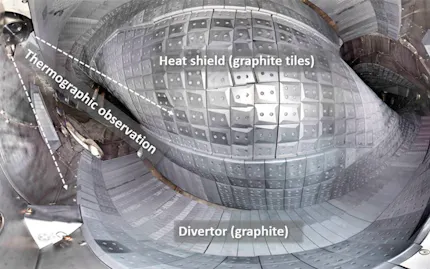

Read more about high-end-thermography with ImageIR® 8300 hp![Thermographic Analysis of a Fusion Plant - Divertor Thermographic Analysis of a Fusion Plant - Divertor]()

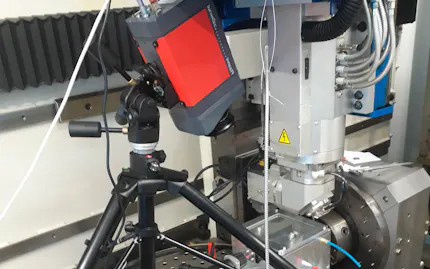

Monitoring Plasma at Wendelstein 7-X

What will the energy supply of the future look like? The Max Planck Institute for Plasma Physics (IPP) in Greifswald is dealing with this question.

Read more about thermographic analysis of a fusion plant with ImageIR® 9300![Thermography InfraTec CWD wind turbines testing Thermography InfraTec CWD wind turbines testing]()

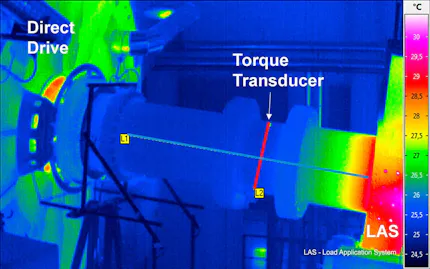

Precise MN·m Torque Measurement in Wind Turbine Test Benches

The generation of electricity power produced by wind turbines is expanding worldwide. This development is associated directly with an increasing demand to test the product reliability, functionality and life durability of wind turbine subsystems like the drive train.

Usage of VarioCAM® High Definition for torque measurement![InfraTec/GOM Webinar InfraTec/GOM Webinar]()

Combination of Digital Image Correlation and Thermographic Measurements

The combination of measuring results from the digital image correlation (ARAMIS, DIC) and temperature measuring data from infrared cameras enables the simultaneous analysis of the thermal and mechanical behavior of test specimens in the materials and components testing field.

Further information about ARAMIS system from GOM and infrared cameras from InfraTec![Early fire detection with WASTE-SCAN monitoring system Early fire detection with WASTE-SCAN monitoring system]()

Early Fire Detection in the Power Plant

Today's power and heating supply in the city of Bern is hardly imaginable without the Forsthaus energy centre (Energiezentrale Forsthaus – EZF). This power plant combines a refuse incineration plant (KVA) with a wood heating power plant and a combined gas‐steam power plant. The Swiss company relies on the WASTE‐SCAN infrared monitoring system from InfraTec for the early fire detection.

Further information about early fire detection in the power plant![Thermal Stress Analysis of Metals Thermal Stress Analysis of Metals, picture credit: © iStock.com / kimtaro]()

Thermal Stress Analysis of Metals

Stress changes during tensile testing provide information about material properties of metals such as tensile strength. With the help of thermographic cameras metallic solid bodies can be tested for such stress changes.

High‐End‐Thermography with ImageIR® 8300 hp![Nickel‐titanium Wires in Tension Test Nickel‐titanium Wires in Tension Test - Picture credits: © iStock.com / tunart]()

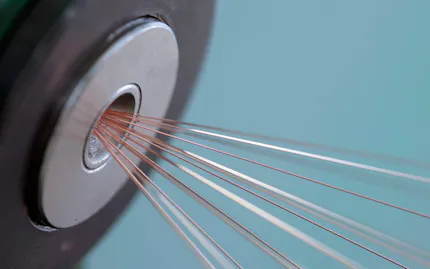

Nickel‐titanium Wires in Tension Test

How do solid materials change structurally? The engineers Prof. Stefan Seelecke and Marvin Schmidt from Saarland University investigate this fundamental question in materials research. Both consider this topic with the help of micro-thermography. Their cutting‐edge basic research ensures that we will have even more energy‐efficient electric devices to use at home in future.

Usage of ImageIR® 9300 at Saarland University![thermal imaging for climate research thermal imaging for climate research]()

Thermography for Climate Research

Climate research is one of the most exposed types of academic research these days. With the continuous discussion about extreme weather events and long‐term implications of human‐made climate factors the related science has become a part of everyone´s daily life.

Thermography for Climate Research![Tire Inspection with thermal imaging Tire Inspection with thermal imaging - Picture Credits: © Vladimir Melnik / Fotolia.com]()

Tire Inspection with Thermography

Mechanically stressed car components like tires are a continuous issue for quality inspection and related R&D improvements. At Bridgestone Corporation in Hofu (Yamaguchi prefecture in South-Western Japan) new test procedures for off-the-road tires for construction and mining vehicles (OR tires) had to be developed to meet the literally growing scale of performance concerning the carrying capacity.

Read more about tire inspection with ImageIR® 8300![Quality Assurance with Active Thermography Quality Assurance with Active Thermography]()

Quality Assurance with Active Thermography in Series Test at Zwickau Volkswagen Plant

Non-destructive testing methods are becoming increasingly more important in the industry. One reason is that they cost much less than other test methods. As a very elegant method, the active heat flow thermography method is now firmly established as a powerful method of non-contact and non-destructive testing of products of different manufacturing technologies.

Usage of ImageIR® to test laser welds of body components![Laser welding at Laser Zentrum Hannover e.V. Laser welding at Laser Zentrum Hannover e.V. - Picture credits: © iStock.com / emituu]()

Thermography in CFRP Processing

Many new systems operate at very high laser intensity levels and consequently require close control of thermal processes. This is achieved by the use of infrared thermography which is both contact-less and provides imagery.

Usage of ImageIR® 8300 at Laser Zentrum Hannover e.V.![Using Thermal Imaging for Optimisation of Installed Wind Turbines Using Thermal Imaging for Optimisation of Installed Wind Turbines - Picture Credits: © visdia / Fotolia.com]()

Thermography for Optimisation of Installed Wind Turbines

Due to the decreasing number of suitable locations for wind turbines and the increasing push towards renewable energy sources, new activities have been introduced to improve the efficiency of rotor blades for wind turbines.

Usage of ImageIR® for Optimisation of Installed Wind Turbines![Inverter with loaded components to forecast their lifecycle Inverter with loaded components to forecast their lifecycle - picture credits: istock.com / Mordolff]()

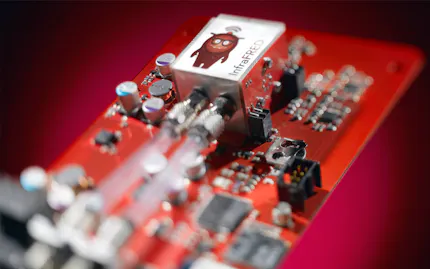

Thermographic Microscopy in Electronics

At the same time that the performance of electronic components is being driven ever higher the demand for thermal management at ever smaller scales is also occurring.

Usage of the infrared camera ImageIR® 8300 at the Fraunhofer-Institut für Silizium-technologie (ISIT)![Infrared thermal imaging applications at “Kunststoff-Zentrum in Leipzig (KuZ)“ Infrared thermal imaging applications at “Kunststoff-Zentrum in Leipzig (KuZ)“ - Picture credits: © iStock.com / aquatarkus]()

Infrared Thermography Applications at “Kunststoff-Zentrum in Leipzig (KuZ)”

Due to relative good emission ratios of many plastics, infrared thermography is suitable for the extended characterisation of plastic processing technology and its optimisation. This application report exemplifies infrared thermography applications for plastic processing and inspection technologies at the KuZ.

Read more abour infrared thermography applications at Kunststoff-Zentrum in Leipzig gGmbH![CCTV system with thermal camera VarioCAM® hr head Vehicle-Bound Mobile Surveillance Solution]()

Vehicle-Bound Mobile Surveillance Solution from InfraTec

2012 marked an important milestone for the Eastern European Countries of Poland and the Ukraine – the jointly rganized UEFA European Football Championship 2012. While this kind of events generate a wide public attraction there are certain background activities which contribute to a seamless progress significantly: Security and logistics are two core tasks to be handled by the relevant local authorities.

Usage of VarioCAM®-series as vehicle-bound surveillance solution![Ladle Hot Spot Detection by InfraTec Ladle Hot Spot Detection by InfraTec - Picture Credits: © iStock.com / kot63]()

Automatic Ladle Monitoring

A ladle typically contains up to 290 tonnes of hot, liquid steel when it is transporting the melted good to the continuous caster. Ladle-temperature measurements with contact-free infrared thermography are an ideal basis for the early detection of impending breakage.

Reliable Thermographic Complete Solutions LHSD from InfraTec![Thermography in Electronics Development Thermography in Electronics Development - Picture credits: © iStock.com / Jimmyan]()

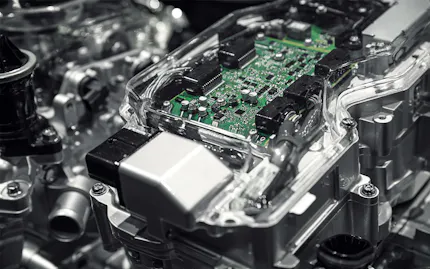

Thermography in Electronics Development

At Delphi’s laboratory plant “Test & Validation Services”, thermography is used for design and product validation as part of quality assurance. Therewith, a stable hardware basis is set for integrating new technologies in motor vehicles that again present a substantial contribution to traffic safety.

Usage of infrared thermography at Delphi Deutschland GmbH![Thermography in quality assurance with PRESS-CHECK Thermography in quality assurance with PRESS-CHECK - Picture credits: © iStock.com / 3alexd]()

Thermography in Quality Assurance

Quality assurance and process enhancement is essential to complex industrial processes. Leading businesses rely on certified quality management, to allow for matters of quality and environmental sustainability even during the early stages of manufacturing development. In co‐operation with a leading automotive supplier, InfraTec GmbH enhanced the automated thermography monitoring solution PRESS‐CHECK to inspect the product quality of press hardening with an accuracy of 100 %.

Automated Infrared Thermography for Temperature Measurement in Industrial Processes![InfraTec thermography reference - Thermal Ceramics InfraTec thermography reference - Thermal Ceramics - Picture credits: © iStock.com / JazzIRT]()

Thermography for Insulation Checks

All kind of hot industrial processes need to be contained well to allow the process itself to go on and at the same time to protect neighbouring installations and employees working there. Thermography helps to detect weak points and provides first indications for necessary repairs.

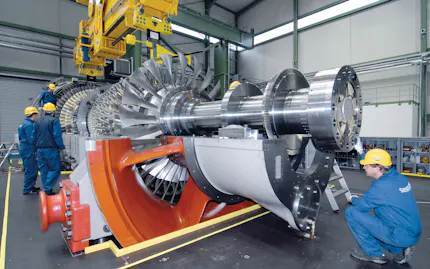

Usage of VarioCAM® series at Morgen Thermal Ceramics![Thermography for Quality Assurance: Testing of turbine blades for gas turbine power plants Thermography for Quality Assurance: Testing of turbine blades for gas turbine power plants / Picture credits: © Siemens Energy Global GmbH & Co. KG]()

Thermography for Quality Assurance

Today gas and steam turbine power plants by the SIEMENS AG are more than ever complex high-tech products. Heavily stressed parts like the turbine blades are tested with the latest measurement techniques for example with infrared thermography.

Usage of ImageIR® 8300 for quality assurance at Siemens AG![Thermography for Building Inspections Thermography for Building Inspections - Picture credits: © Pexels / Felix Lauster]()

Thermography for Building Inspections

ARCHIMEDES Facility-Management GmbH uses its infrared camera predominantly for revisions and securing of quality standards during the construction phase of newly erected buildings and the refurbishment of older buildings. Thereby the detection of construction faults like thermal bridges, poor insulations or air leakages plays a major role.

Usage of VarioCAM®-series for building inspections![Study of bats Study of bats - Picture credits: © iStock.com / fermate]()

Thermography for Environmental Studies

In order to protect bat populations firstly their ecology has to be understood but it can be very difficult to study the small, nocturnal mammals in the wild. Infrared thermography offers solutions to many of the problems faced by bat ecologists.

Monitoring of bats with VarioCAM®-series![Thermography in Process Automation - Isabellenhuette Thermography in Process Automation - Isabellenhuette]()

Thermography in Process Automation

The company Isabellenhütte Heusler GmbH & Co. KG has identified this potential at an early stage and uses infrared thermography for the quality assurance of their low resistance precision resistors.

Usage of VarioCAM®-series at Isabellenhütte Heusler GmbH & Co. KG