Ernergy Miracle with Natural DNA

What does your breakfast egg from the weekend, a cornfield and a large portion of french fries from a fast-food restaurant have in common? They all provide raw materials for a biogas plant. Organic substances such as egg shells, corn or potato peelings are decomposed there naturally under airtight sealing. The result is an energy-rich and extremely versatile product – biogas.

Biogas can be converted into electricity, heat, gas or fuel. Its more important element is the combustible methane. The methane content varies between 50 and 65 percent depending on the raw material used, from which the biogas is produced. In addition, carbon dioxide occurs with a share of 35 to 50 percent. Furthermore, small concentrations of nitrogen, water, oxygen and hydrogen sulphide are found in the gas.

Specialist for the processing of biogas

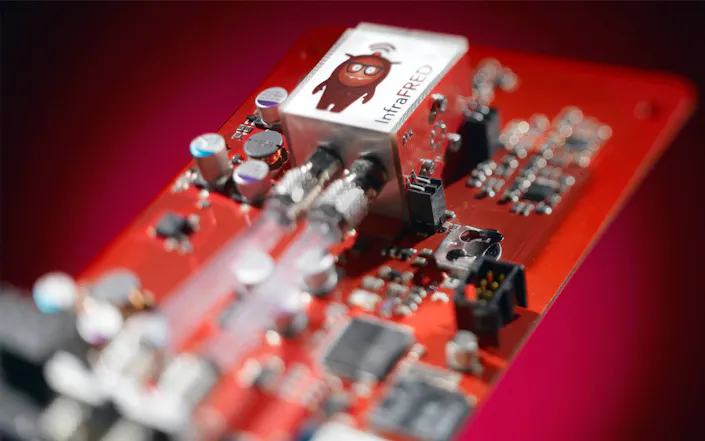

Anyone who wants to use a sensor specially for applications involving biogas needs a solution that measures methane (CH4) and carbon dioxide (CO2). The Bavarian company Awite Bioenergie GmbH has developed a non-dispersive infrared sensor in double beam technology suitable for this purpose. To ensure that this meets its specific purpose, it has a very low cross-sensitivity of the CH4 measured value particularly in relation to other hydrocarbons. The cross-influences of the gases being tested are adjusted within the sensor.

The determination of the exact proportions plays a crucial role, for example, when it involves the conversion of biogas to biomethane. The latter can be fed into Germany’s natural gas grid. Provided that it has the same decisive properties as natural gas. Exact percentages are decisive here. Why? The respective energy suppliers have different requirements. For a feed-in, the minimum methane content is between 85 and 98 percent, depending on the requirements. Once fed into the existing gas network, biogas, for example, can be filled up at the fuel pump of a gas filling station. Since liquefied bio-methane (LNG = Liquefied Natural Gas) has an even higher energy density, even lorries and ships can be driven with it.

Use of Pyroelectric Detectors in Practice

One advantage of pyroelectric detectors is the versatility of their applications. Detecting and analyzing gases and gas mixtures, investigating the material composition of organic and inorganic compounds, monitoring flames – all this is of great importance in a wide range of industries. Selected examples will help you to get to know some of the possible applications and, at best, to gain valuable ideas for solving your own measurement and testing tasks.