Pyroelectric detector

A Pyroelectric detector is an infrared sensitive optoelectronic component which are specifically used for detecting electromagnetic radiation in a wavelength range from 2 to 14 µm.

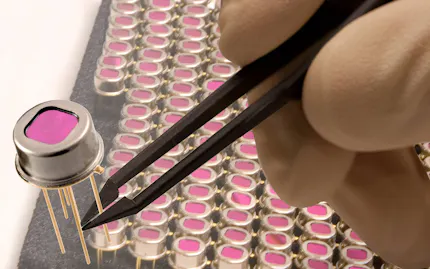

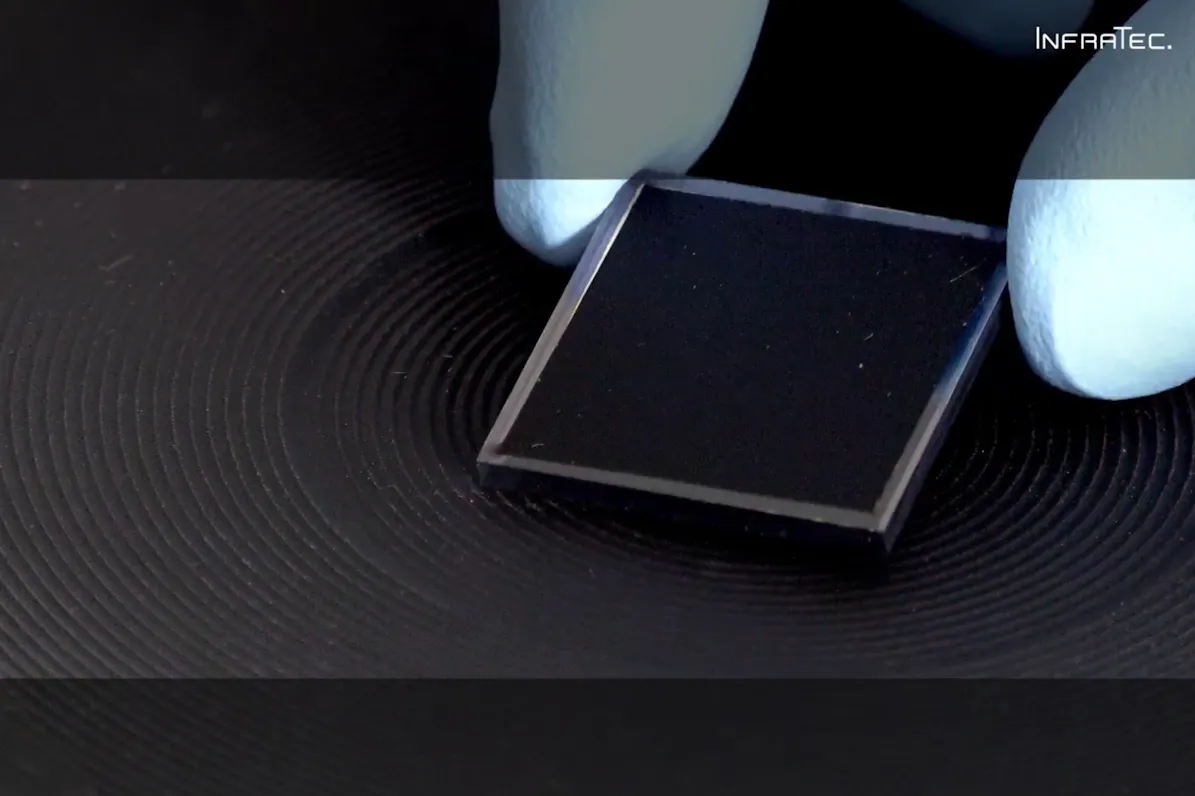

A receiver chip of a pyroelectric infrared detector manufactured by the sensor division of InfraTec consists of single-crystalline lithium tantalate. Because of its very high curie temperature of 620 °C lithium tantalate guarantees an extremely low temperature coefficient with an excellent long-term stability of the signal voltage.

How Does a Pyroelectric Detector Work?

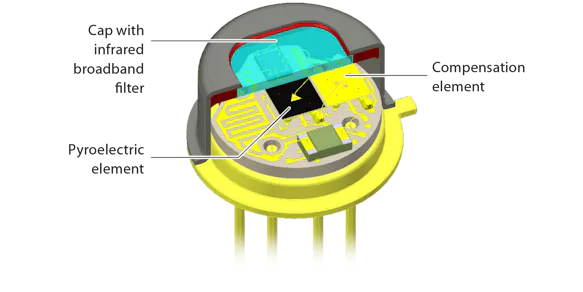

Pyroelectric crystals have a rare asymmetry due to their single polar axis. This causes their polarisation to change with temperature. This so-called pyroelectric effect is used in sensor technology. For this, a thin pyroelectric crystal is coated perpendicular to the polar axis with electrodes. On the upper electrode of the crystal, an absorbing layer (black layer) is applied. When this layer interacts with infrared radiation, the pyroelectric layer heats up and surface charge arises. If the radiation is switched off, a charge of the opposite polarity originates. However, the charge is very low. Before the finite internal resistance of the crystal can equalise the charges, extremely low-noise and low leakage current field-effect transistors (JFET) or operational amplifier (OpAmp) convert the charges into a signal voltage. Thermopiles, too, belong to the group of thermal detectors, however, the measuring effect is less significant. While pyroelectric infrared detectors show a good signal/noise ratio up to modulation frequencies of 4 kHz, e.g. in FTIR spectrometers, thermopiles produce good results up to modulation frequencies of specific Hertz only.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our experienced engineers, receive further technical information or learn more about our additional services.

Experiment: The Pyroelectric Effect

Changing the temperature of the crystal material lithium tantalate (LiTaO

The Pyroelectric Effect – with a black coated LiTaO3 crystal

Pyroelectric Detector with Integrated Beam Splitter by InfraTec

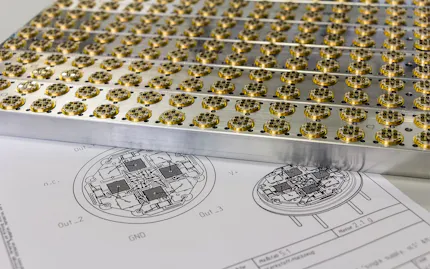

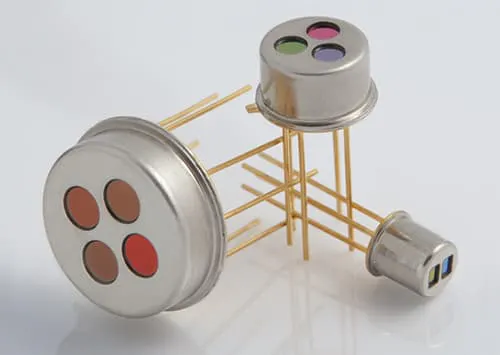

In addition to the pyroelectric crystal, a pyroelectric infrared detector by InfraTec contains optical and micro-mechanical components. Two-channel and four-channel pyroelectric detectors with integrated beam splitter and integrated CMOS amplifier are micro-systems consisting of components which function thermally, electronically and optically.

As pyroelectricity is a characteristic of a subgroup of piezoelectric crystals, a pyroelectric detector reacts to airborne and solid-borne sound. This effect is often called microphony. However, a patented fastening of the pyroelectric chip by InfraTec reduces these negative effects for pyroelectric detectors dramatically so that in many cases these negative effects are in the order of magnitude of other interference voltage or of the inherent noise of the infrared detector only.

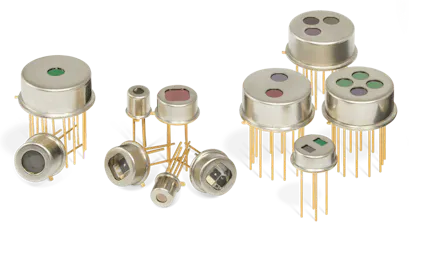

Detector Search

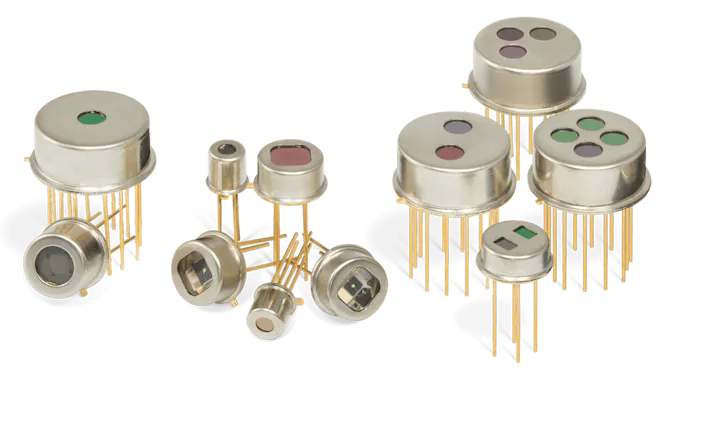

InfraTec offers different product groups including approximately 50 standard pyroelectric detectors. Detectors with reduced microphone technology and integrated operational amplifier as well as digital detectors are part of our product range.

Choose your suitable infrared detectors with the help of our detailed detector search.