PyrIQ – Digital Detectors for Easy System Integration

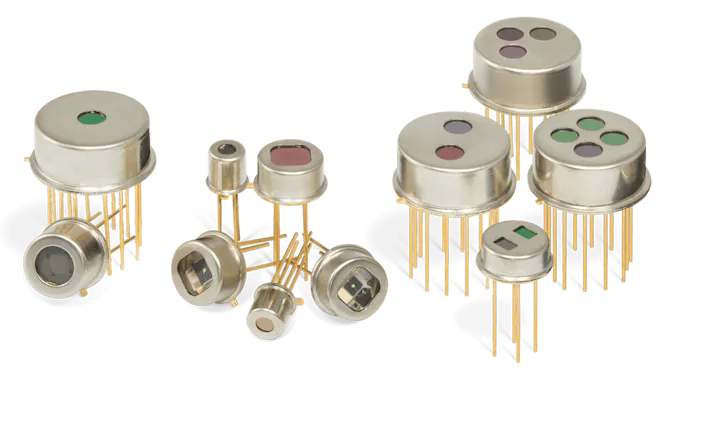

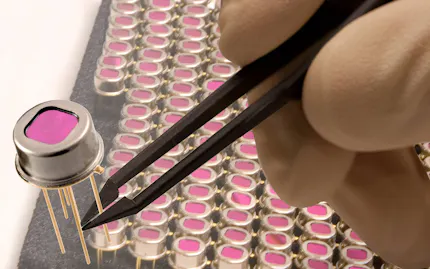

We are introducing: our digital detector for easy system integration with variable signal processing and improved electromagnetic compatibility (EMC). Like all detectors from InfraTec, it is based on single-crystal lithium tantalate (LiTaO

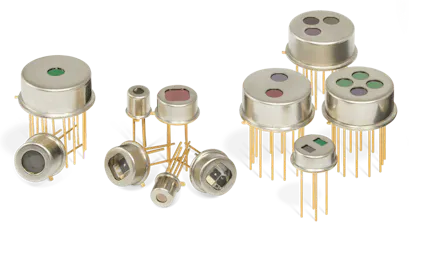

Type | close Number of measuring channelsNumber of Channels | close TO18, TO46: 5.4 mm in diameter Housing | close Size of the circular or rectangular aperture through which radiation hits the sensitive elements.Aperture (mm) | close Voltage Mode: The pyroelectric current is initially converted into a voltage by an RC network followed by a conversion to lower impedance. Current Mode: The pyroelectric current is permanently compensated by an OpAmp. The current required for this generates a voltage drop across an RC network in the feedback path which serves as the measurement signal. Operating Mode | close Integrated signal condition like integrated junction field effect transistors (JFET) for detectors in voltage mode or integrated operational amplifiers (OpAmp) for detectors in current mode. Amplifier | close A pyroelectric detector is sensitive to changes in temperature. Changes in ambient temperature have an influence on the measurement signal and shifts the operating point. This effect reduces a thermal compensation. Therefore, each pyroelectric element gets an additional optically inactive element, which compensates for unwanted currents. Thermal Compensation | close Patented micromechanical chip attachment (LowMicro) by InfraTec to reduce the effects of interfering impact sounds. Low Micro | close As a key parameter, the specific detectivity D* characterizes the signal-to-noise ratio of infrared detectors. Specific Detectivity* | |

|---|---|---|---|---|---|---|---|---|---|

| 4 | TO8 | 8.5 x 8.5 | Current Mode | PyrIQ | 2.4 *** | ||||

| 2 | TO39 | ø 6.0 | Current Mode | PyrIQ | 1.5 *** |

* in 10

** in 10

*** bei R

**** in 10

Application Areas

The digital detector is ideal for simple system integration in gas analysis and flame detection. By using the digital detector, the user receives a digital measurement signal that can be read out and immediately processed.

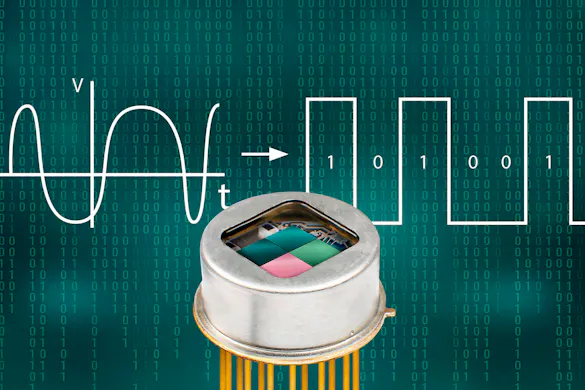

For high-precision measurement, especially in gas analysis, synchronisation of the emitter and detector clock is necessary. For the digital pyroelectric detectors, a clock input (pin) is available for this purpose, which is used to specify the system clock or the exact sample time. This allows a time signal with a highly precise sampling rate to be generated. Another special feature compared to analogue technology of our digital detector is the “Fast Recovery after Saturation”. This function detects overdriving due to a faulty operating condition – for example, due to extreme temperature fluctuations or mechanical influences – and automatically resets the analogue front-end.

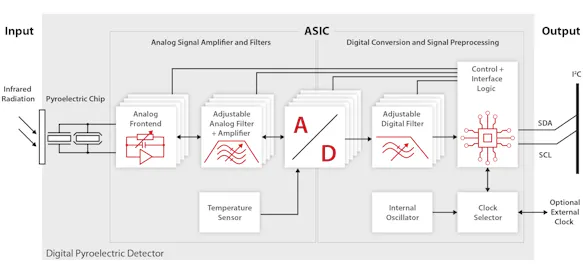

The digital detector converts the analogue signal, which can be filtered and amplified in several stages, directly into a digital signal with a 16-bit resolution. The entire signal processing is carried out by an ASIC (Application- Specific Integrated Circuit), whereby the analogue front-end acts like a classic transimpedance amplifier. Thus, users receive a digital measurement signal that can be read out via an I²C interface and immediately processed.

White Paper Digital Detector – Startup a Detector with Digital Interface

This white paper is intended to show how to put the digital detector into operation with a basic microcontroller board like the Arduino Uno. You will also learn how to configure the detector and retrieve data.

PyrIQ® Evaluation Kit – Detector Configuration in Just a Few Steps

The PyrIQ® Evaluation Kit from InfraTec supports customers in the initial testing of the digital PyrIQ® detectors without the otherwise required development of software, firmware and test circuits. The associated software allows the detector and IR source parameters to be set via an intuitive graphical user interface. Our Evaluation Kit offers an easy way to utilize the wide range of setting options for PyrIQ® detectors, speeding up the configuration and development process. In addition, the kit is also suitable for comprehending the mode of operation of an analog pyroelectric detector and the influences of its electronic components.

Evaluation KIT for digital detectors: A quick test setup to validate or develop your own test setup and determine the right parameters for your measurement task.

White Paper Digital Detector – Configuration of Your PyrIQ Detector

This white paper is intended to help you find a suitable PyrIQ-configuration for your application by following a “good practice”-strategy as well as stating the effects and potential drawbacks for all available PyrIQ-parameters.

Analogue vs. Digital – Which Detector for which Application?

Analogue pyroelectric detectors have proven their worth for decades. Their integration into the device design can be made flexible but requires a high degree of electronic skill. The performance of the detectors can be fully utilised. Considering the effort required for system integration, digital pyroelectric detectors have clear advantages. The functions already integrated into the detector – although limiting the scope for design – significantly reduce the effort required for system integration. The following table provides a quick overview of advantages and disadvantages:

| Digital pyroelectric detectors | Analogue pyroelectric detectors | |

| Detector series | LRD, LID | LIE, LME, LIM, LMM, LRM |

| Properties | Detectors with integrated ASIC for transimpedance amplification, 16-bit A/D conversion and signal conditioning | Maximum flexibility for system integration by the user (free choice of external A/D converter and interface) |

| Electromagnetic compatibility (EMC) | ++ | + |

| Integrated temperature measurement | Yes | Yes (available for LRM) |

| Flexible adjustment of feedback components | Yes (Rf = 2 GΩ … 1 TΩ; Cf = 50 fF … 6.4 pF) | No |

| Requirements for system integration on the device side | Low | High |

| Power consumption (typical) | 1 mW | 0.1 mW |

| Signal to noise ratio | + | Current mode ++ / Voltage mode +++ |

| Sampling rate (maximum) | 1 kHz | Free to select |

| Max. Modulation Frequency | 100 Hz | 4 kHz |

| Supply voltage | 1.8 … 3.6 V | Up to ± 5V |

Download Flyer

Download the flyer about the digital detectors and learn more about the possibilities using a digital detector.

Various Fields of Application for PyrIQ Detectors

Digital detectors are just as suitable for the use in gas analysis and flame sensing as detectors with analogue signal output. But especially if the environmental conditions require a compact and easy-to-integrate detector, a detector with integrated digitisation will be a good choice. Thus, among other things, the digital version is suitable for the field of air-conditioning and building technology when it comes to measuring air quality. Since this correlates well with the carbon dioxide concentration in the air, the CO

Further Possible Applications for the Digital Detector:

Agricultural industry, for example for monitoring the atmosphere in greenhouses and in research projects on plants

Gas detectors for explosive gases, for example for mining or drilling platforms

Process gas analysis, for example for measuring exhaust gases in industrial plants

Detector Search

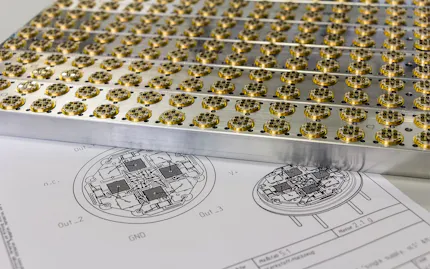

InfraTec offers different product groups including approximately 50 standard pyroelectric detectors. Detectors with reduced microphone technology and integrated operational amplifier as well as digital detectors are part of our product range.

Choose your suitable infrared detectors with the help of our detailed detector search.