Infrared Spectroscopy

Infrared spectroscopy is a well-established and widely spread measurement method in sensor technology. Due to the physical nature of the underlying sensing principle – infrared absorption of molecules – it is the technology of choice to highly selectively and stably determine concentrations of materials and compositions of mixtures of substances. InfraTec produces various detectors for analytical instruments and spectrometers.

Broadband Detectors for Laser and FTIR Spectroscopy

InfraTec's PYRONEER high-performance detectors are used in spectroscopy. Depending on the requirements of the test task, these are based on high-quality lithium tantalate (LiTaO

Thanks to a special precious metal black layer, the high-performance detectors absorb radiation extremely uniformly over a very wide wavelength range from 2 µm to well over 20 µm.

For spectrometer applications, pyroelectric detectors can be optimized with regard to the time constants to ensure short reaction times and modulation frequencies up to a few kilohertz. Customers use our detectors in highly specialized laser spectrometers for the measurement of lowest gas concentrations down to ppb level as well as in universally usable FTIR spectrometers.

Detector Search

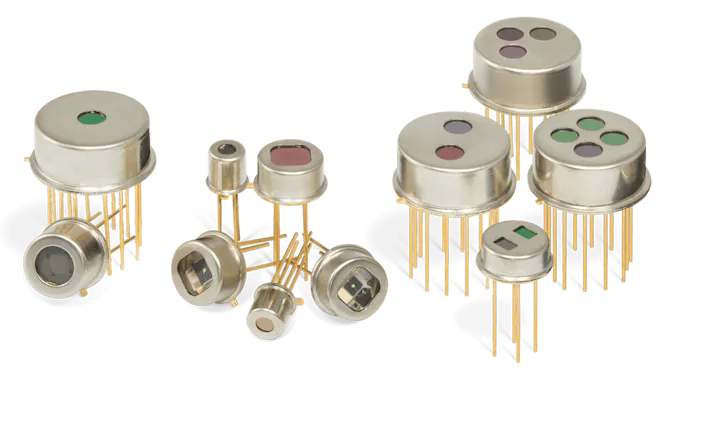

InfraTec offers different product groups including approximately 50 standard pyroelectric detectors. Detectors with reduced microphone technology and integrated operational amplifier as well as digital detectors are part of our product range.

Choose your suitable infrared detectors with the help of our detailed detector search.

Applications of Infrared Spectroscopy

Knowing the exact composition of solids, liquids and gases is relevant under different aspects. Usually the quality and quantity of any organic and inorganic compounds are to be determined. The applications of infrared spectroscopy are correspondingly broad. The method is often used for the following purposes:

Environmental and climate research: measure emissions, identify plastics in waste sorting, detect leaks on supply lines, determine the composition of the atmosphere

Measurement on surfaces: detect contaminants, ensure complete coating with lubricants, determine the type and thickness of coatings

Explosive atmospheres: e.g. detect if dangerous substances in the form of gas, vapour or mist are present

Medical technology: monitor anaesthetic gases, capnography, determine the chemical composition of tissue by spectral measurement to detect diseases, test breath alcohol

Oil analysis: e. g. monitor the condition of used transmission oil

Food quality control: e.g. analyse the composition of food ingredients

Forensics: e.g. identify textile fibres, identify counterfeits

Pharmaceutical analysis: test newly formulated medicinal products

Analysis of polymers and plastics: e. g. identify compounds, identify impurities

Process control: e.g. monitor the compliance with material specifications

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our experienced engineers, receive further technical information or learn more about our additional services.