Infrared Reflexions

Find out about the latest innovations and further developments in the field of infrared thermography. More than 5,000 users around the world already rely on innovative quality products by InfraTec

Read in the Current Issue

TarisIR® mini – When Size Matters!

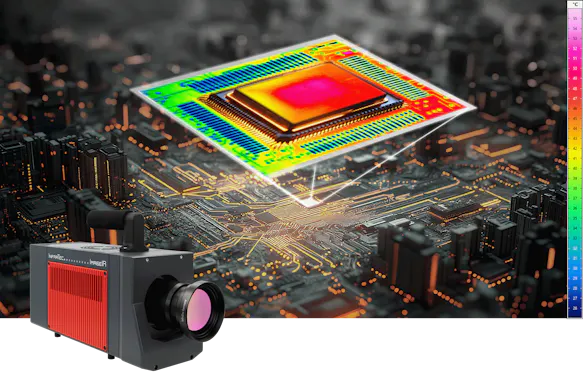

The Usual Way? We Don't Want That! – We focus on individuality: ImageIR®

ImageIR® 12300 – High-end Thermography with Maximum Native IR Resolution

ImageIR® 6300 – MWIR Infrared Camera for Continuous Operation

The View Into Distance: 100 mm Telephoto Lens

We have Recategorised! – Overview Camera Portfolio

Avoid Fire Sources! – FIRE-SCAN for Li-Ion Batteries

Further Development of Thermographic Measurement Methods

Our Service – Your Benefit

Measuring and Testing with Thermography – Case Studies from InfraTec

We hope you enjoy reading our Infrared Reflections and that we can continue to enthuse you about the world of thermography.

When Size Matters!

Our compact, radiometrically calibrated TarisIR® mini infrared camera enables entry into stationary thermal imaging at an excellent price-performance ratio.

In continuous operation, it provides reliable and position-independent thermographic real-time image data with up to 50 Hz full-frame frequency. Due to measurement in the long-wave atmospheric window of (8 ... 14) µm, TarisIR® mini is also ideally suited for outdoor monitoring.

The Usual Way? We Don't Want That!

With the cameras in our ImageIR® series, we provide our customers and partners with precisely the thermographic system that delivers the best results for their measurement and inspection tasks. For this reason, all infrared cameras in this series have a modular design. This means that each model can be configured according to the user's requirements.

A New Level of Detail

The new ImageIR® 12300 from InfraTec is the radiometrically calibrated infrared camera with the world's highest commercially available native resolution of 5.2 megapixels. With the powerful top model of our ImageIR® series, very fine structures on large-area measurement objects can be resolved with unrivalled detail.

MWIR Infrared Camera for Continuous Operation

The ImageIR® 6300 enables entry into the device class of infrared cameras with cooled photon detectors. This camera offers users enormous performance advantages at a very good price-performance ratio. Due to state-of-the-art SWaP technology and a robust, very compact design, this camera is ideally suited for demanding OEM and continuous operation applications.

The View Into Distance: 100 mm Telephoto Lens

In order to create an even wider field of application for the SWIR cameras ImageIR® 8100 and ImageIR® 9100, the lenses portfolio for these two infrared cameras has been expanded to include a 100 mm telephoto lens. This enables both system cameras to capture objects at great distances in detail and measure temperatures.

We have Recategorised!

InfraTec's camera portfolio grows from year to year and the variety of possible applications increases with each new infrared camera. To give you an immediate overview of which camera could be suitable for your application, we would like to introduce you to our updated product categories.

Avoid Fire Sources!

Based on a tried-and-tested modular system, we offer individually configurable system solutions that are tailored precisely to your requirements. One of these system solutions for object and warehouse monitoring is FIRE-SCAN, e.g. for the production and storage of Li-ion batteries.

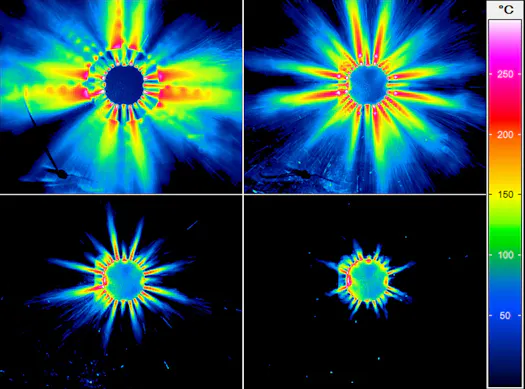

Further Development of Thermographic Measurement Methods

As a partner of national and international universities, research institutes and companies from various sectors, we are involved in numerous research projects. The knowledge gained from these projects drives us forward effectively and purposefully in the continuous optimisation of our technologies.

Our Service – Your Benefit

InfraTec does not just sell thermography systems. We support you from the initial consultation all the way to the right product and its use. With our warranty services and 24-hour hotline, we are always here to help you.

Measuring and Testing with Thermography

Renowned companies from all industries around the world trust in InfraTec products. Get to know our thermography systems even better and find out first-hand how our solutions are used in practice.