Thermal Micro Actuators for Nanotechnologies

Microelectromechanical systems (MEMS) offer a wide range of possible applications in the field of nanotechnology. Everyday examples are the position recognition of mobile phones and the use in airbags, digital cameras or pacemakers. Other applications can be found above all in the field of miniaturised medical diagnostics. Growing demands on miniaturisation affect both the system solutions required for this and the sensors and control elements to be developed.

Micromechanics as Support for Future Nanotechnology Applications

The Professorship of Microsystems and Biomedical Engineering at the Chemnitz University of Technology is working on MEMS-based micro actuators that are intended to serve as a control platform for analyses of nanocomponents and are only a few micrometres in size. Similar to conventional electromechanical positioning tables with three degrees of freedom, the aim is to enable high precision of horizontal or vertical movement of nanocomponents.

InfraTec Solution

Chemnitz University of Technology

Professorship of Microsystems and Biomedical Engineering

www.tu-chemnitz.de/etit/microsys/index.php

Dr. Sebastian Voigt

Thermal Imaging System

ImageIR® 9300 infrared camera

ImageIR® 9300 and Thermography on Miniaturised Actuators

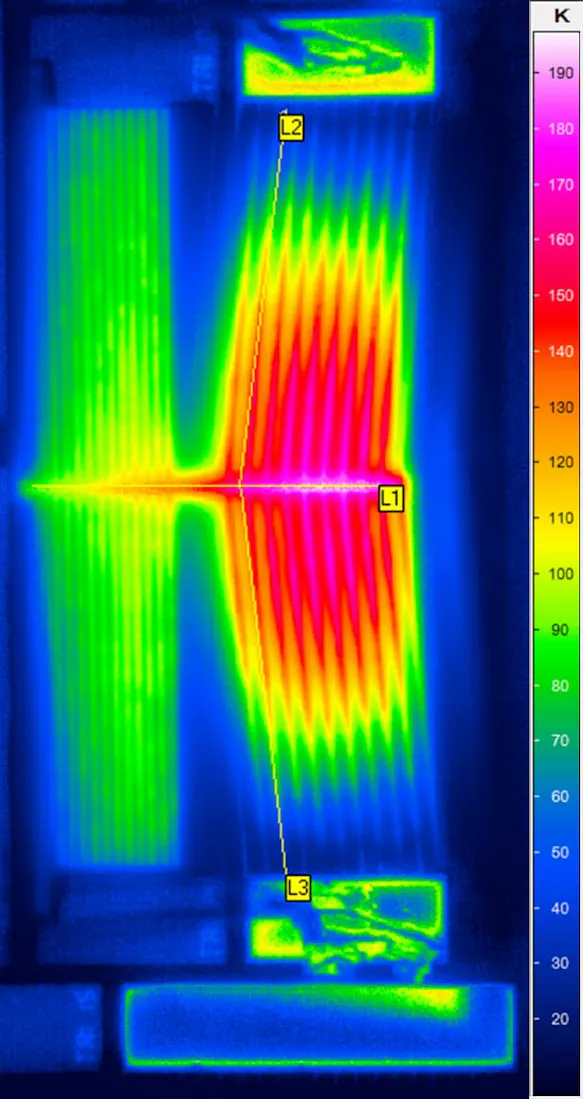

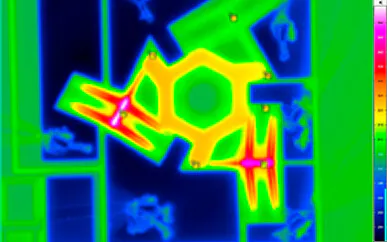

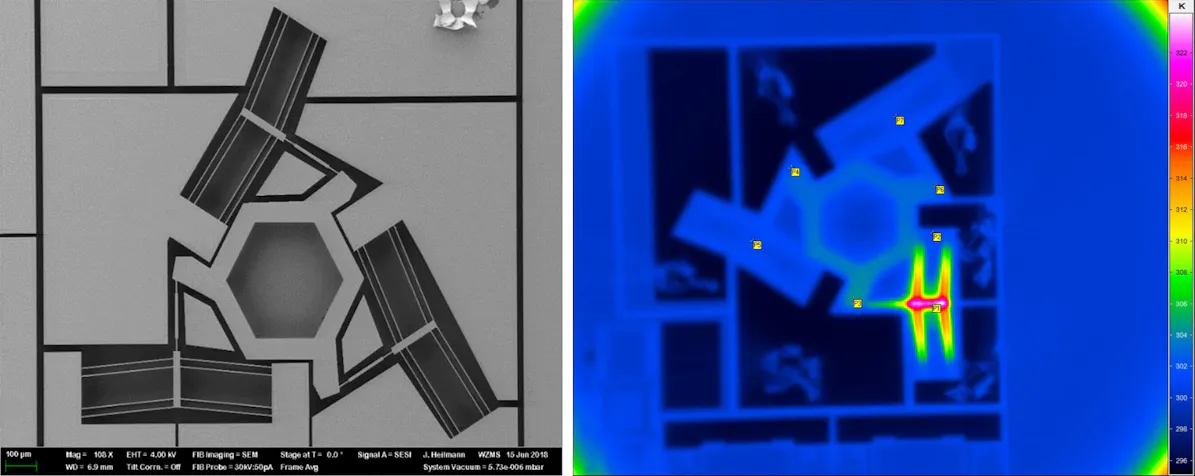

The professorship was able to transfer 20 years of experience gained in the domain of electrostatic actuators to thermally driven actuators. The latter allow the use of electron microscopes for MEMS analysis, which would not have been an option with electrostatic actuators. Prototypes for thermal actuators have already been developed at Chemnitz University of Technology enabling motion control with an accuracy of up to 2 µm and 0.3°.

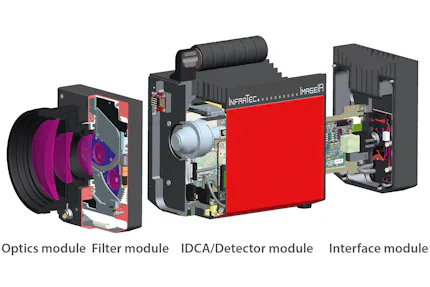

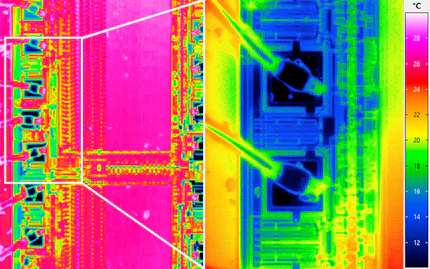

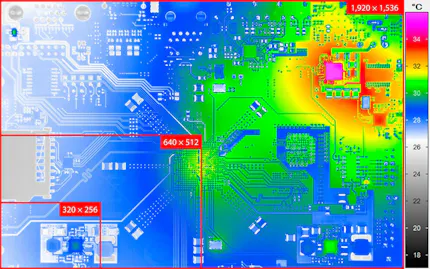

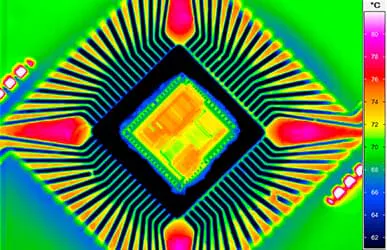

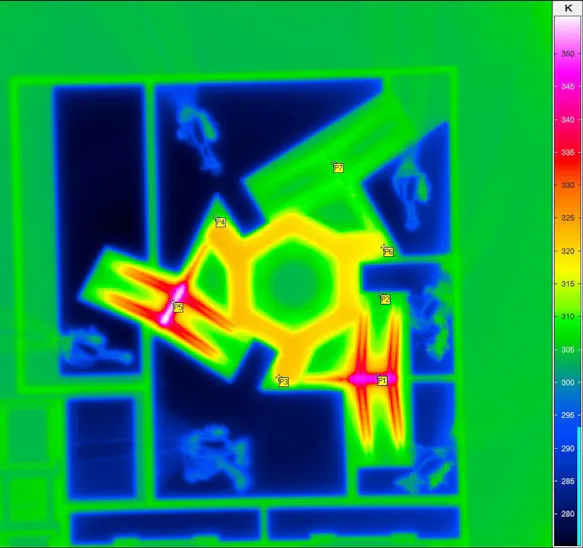

Achieving such precision requires a precise analysis of the material parameters on the actuators used. As expected with thermal actuators, the most important factor is measuring the component temperature as accurately as possible. Due to the very small dimensions and mechanical characteristics of these measurement objects, only the most sophisticated infrared cameras come into consideration. A microscopic lens was selected and combined with the large infrared detector of the ImageIR® 9300 with (1,280 × 1,024) IR pixels to achieve a resolution in the µm range and a large field of view to capture the peripheral components around the actuators.

Diffraction-limited Resolution

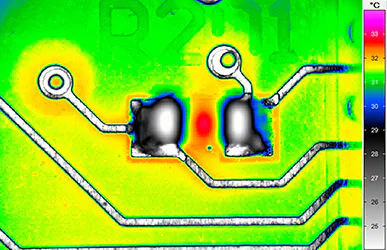

An ImageIR® 9300 with an M=8.0x microscope lens is used at Chemnitz University of Technology. With the spectral range of (1.5 ... 5.5) µm, this system reaches the limit of resolving power that is physically possible. Due to the experimental determination of the emissivity of individual test materials, the measured values obtained enable the determination of heat transfer coefficients and other material parameters. The evaluation is carried out with the IRBIS® 3 professional thermography software. In addition, a lock-in thermography test station with the InfraTec IRBIS® active solution is used for real-time active thermography. Since measurements are taken on silicon and aluminium, the emissivity coefficients are very low and require careful application of special correction models, a feature of the IRBIS® software used.

Results

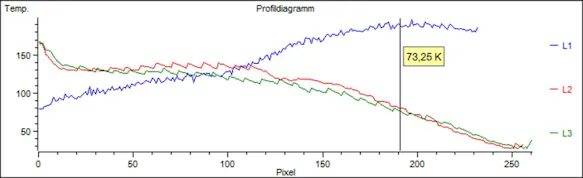

The results presented illustrate the thermal processes within the MEMS structures very clearly. Nevertheless, details remain that need to be clarified:

Working on the redesign of the actuators to reduce thermal crosstalk of the components.

Searching for a measurement method for holistic motion detection based on automated image evaluation of thermal images.

Also in view is an attempt to quantify the thermoelastic damping in the MEMS springs at excitation frequencies up to approx. 10 kHz. These analyses also require the high-precision trigger interface of the ImageIR® 9300 in order to be able to follow quickly and precisely with the help of active thermography. At this point, the ability of lock-in thermography to display the smallest temperature differences will increasingly take effect.

Future applications will make even greater use of nanotechnological components, especially in the field of miniaturised medical diagnostics and analytics. The analyses presented and the use of the ImageIR® 9300 provide insights into the performance of MEMS components required for this purpose in order to advance their development.