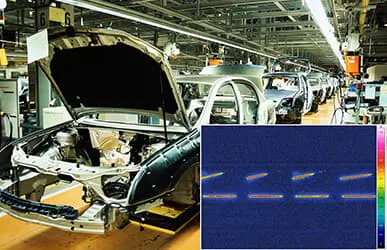

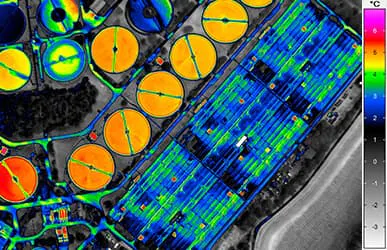

Overview of Benefits

Very high individualisation of the camera

Investment security due to subsequent adaptation of the camera performance to increased measurement requirements

Functional extension and upgrading options due to interchangeable units

Complete thermal decoupling of the detector module for the best possible athermalisation of the entire system

Protection degree IP54 for inside and outside use

Robust light metal housing with protection degree compliant LEMO® plug connectors

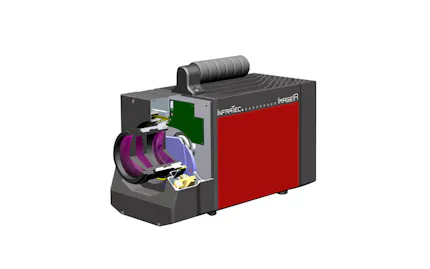

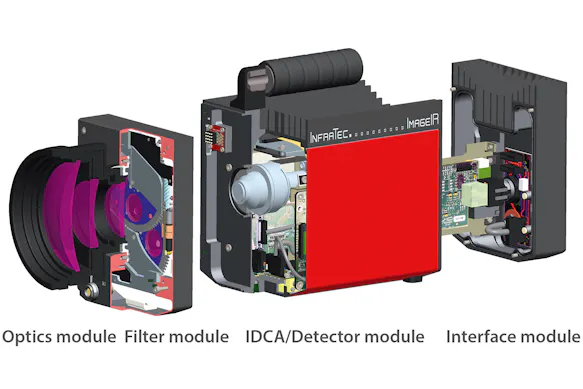

Modular Design of Infrared Camera ImageIR®

Optics Module

From the 200 mm telephoto lens to the 8.0× microscope, the front module incorporates all lenses, even the associated motor-focus system with autofocus option. This allows the greatest possible adaptation to the required geometrical resolution and the matching image field. The complete thermal decoupling from the detector module reduces the influence of dissipated heat to a minimum.

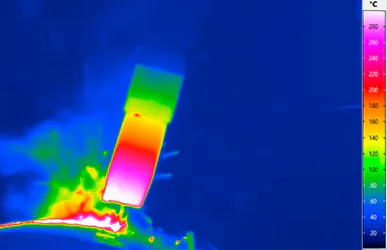

Filter Module

Up to two motorised rotating filter wheels / aperture wheels, which can be fitted with up to six individual items per wheel, can be integrated into this module. In this way, a maximum measuring range selection and optimisation for spectral thermography can be achieved. A MicroScan unit or a fast-rotating filter wheel for HDR thermography (HDR = High Dynamic Range) can also be integrated to expand the number of measuring points or the real-time dynamics of the infrared scene. This module is also designed in such a way that it is completely thermally decoupled from the detector module in order to achieve maximum athermalisation of the camera.

IDCA/Detector Modul

The detector cooler unit is installed in the core module of the ImageIR®. Optimised temperature management is responsible for the maximum service life of the system and long maintenance intervals. It offers an abundance of installations options of different detectors, from the high-speed system with 105 kHz imaging rate to full HD resolution.

Interface Module

This module can be equipped with numerous interfaces such as 10 GigE / GigE or CAMLink / 2xCAMLink to transmit measured data directly without loss to a conventional control and acquisition computer with maximum image frequency and to enable external remote control of the camera.

A wide range of application-specific trigger options can be achieved here to ensure a highly precise, repetitive time / event controlled data recording, as is often necessary for active thermography applications and automation solutions. Furthermore, this module can be equipped with configurable digital inputs and outputs to control the camera and to transmit control signals for external devices.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.