In-process Industrial Temperature Measurement – INDU-SCAN

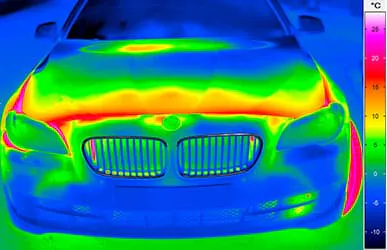

Contactless measurement of temperature distributions and profiles with industrial thermographic cameras permits efficient monitoring and control of temperature-dependent processes and procedures within a system-integrated quality assurance programme in industry.

In-process Temperature Measurement at its Best – INDU-SCAN 4.0

Customised automated thermography solution based on many years of experience and intensive analysis of the respective thermal signatures by our development and application engineers

Professional pre-analyses and selection of camera heads and optics according to strict technical measurement criteria of the inspection task ensure correct implementation

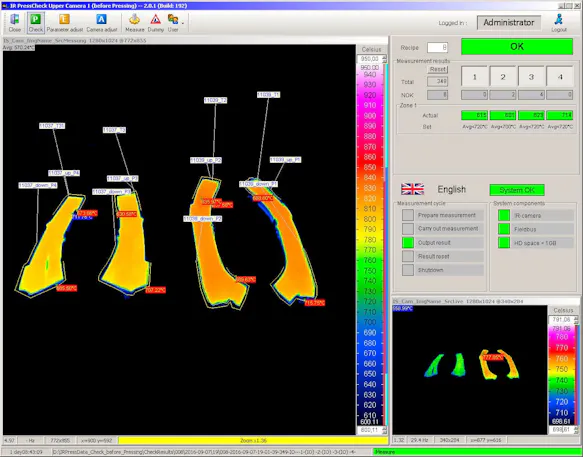

Recognition of components and their spatial location (machine learning) as the starting point for simultaneous, partially multi-stage multi-spot analysis

Positioning of components using various algorithms

Transformation of non-linear thermal signatures and heat flows using state-of-the-art software tools incorporating experience-based algorithms

Technical implementation based on a flexible hardware and software kit for fast integration of customer-specific requirements

Application of powerful, industrially proved components, that are capable of continuous use

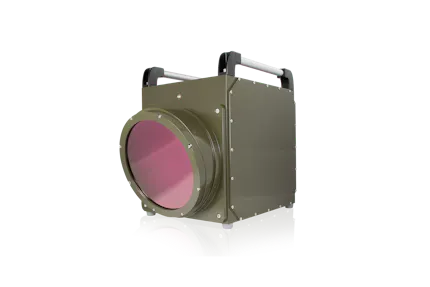

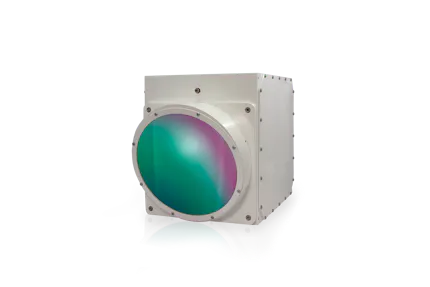

Selection between thermographic cameras of different performance classes and spectral ranges, application-specific protective housings and modular system control units

Individually configurable system software for smooth interaction of all components

Flexible Data Inclusion Thanks to Industry-suitable Interfaces

Data and network management in the era of Industry 4.0 requires flexible and scalable system solutions that can be reliably integrated into plant and machine complexes. The transfer of digital data from cameras to process control INDU-SCAN uses modern interfaces such as GigE / 10 GigE and, if necessary, with increased transfer security or longer distances via fiber optics. The connection to the machine control is done via field bus interfaces like PROFINET, PROFIBUS, CC-Link, Modbus and others. Using TCP/IP protocol, specific quality data can be transmitted for processing and storage in central systems. Storing thermographic and other data in a database allows for a comprehensive evaluation of infrared images and sequences. Furthermore, the database offers an interface for storing the quality data in external database systems. By using these results, you can refine your documentation or based on these results directly control your processes. For this purpose, measured values are compared in real time with defined threshold and limit values. Depending on the result, an event that has been predetermined by you will then be triggered, for example an alarm.

Comprehensive Service from a Single Source

Complete pre-engineering by InfraTec

Electrical and mechanical engineering (EPLAN, CAD)

System development and documentation

Installation and commissioning on site

Customer-specific system training

Comprehensive, competent and reliable service throughout the entire operating life

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

INDU-SCAN Software Kit, Suitable for Industrial Process Control

Application-specific operating and user interface based on the software kit

Simple integration of extensive data analyses

Transmission of the measured values

Exact coupling of the image to the process cycle, synchronous use of temperature data for process control and quality monitoring possible

Recipe management, configurable and editable offline

User management with different security and protection levels

Product Flyer

Get all the information you need at a glance in our product flyers

Use INDU-SCAN for These Industries & Applications

INDU-SCAN in Plastic Welding

With thermography, various processes in plastic welding can be monitored precisely and without contact, e.g. regarding the geometry of the welding zone and material closure. This allows efficient quality control and assurance.

Thermography systems

Enable quality control of the plastic weld seam during the manufacturing process

Detect errors of joining part temperatures

Identify shape/size errors as an indication of just partially joined components

Detect position errors with reference to incorrectly positioned tools and joined parts

Allow conclusions to be drawn about material defects, cavities, inclusions, holes, etc.

Take over the thermal testing in the process cycle

Test and characterise joint connections, e. g. laser welded joints, adhesive joints

Enable adapted signature analysis

Features and capabilities of our thermography solution for plastic welding:

Fast triggered thermographic camera

Adapted recipe creation and processing

Full system integration for series production; remote control and logbook

Industrial control unit

INDU-SCAN for Improved Process Stability in Die Casting

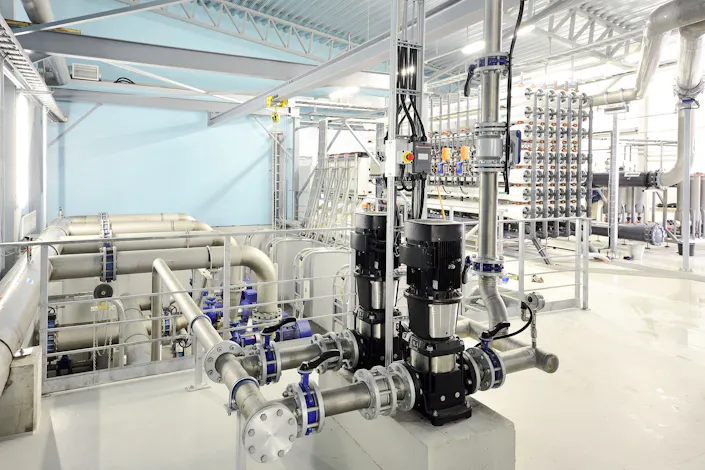

Pressure die casting is an efficient industrial process for the mass production of parts made of non-ferrous metals such as aluminium and magnesium alloys. Modern automated pressure die casting systems are used to manufacture complex components that are sometimes very large and at the same time delicate. High product quality of these castings requires a reproducible process, especially with regard to their dimensional accuracy, strength and surface quality. This is subject to a wide range of influencing factors.

To avoid cavities and shrinkage porosity during production, the highest demands are therefore placed on the die casting machine itself, especially with regard to the design, suitability for continuous operation and stability of the tools used.

The machines and tools must be operated within narrow thermal process windows. This requires direct inline monitoring and control of the production process of each individual component. In this context, the assessment of the temperature distribution in the die casting mould is particulary important. The customised thermography automation solution INDU-SCAN with application-specific design for die casting processes is ideally suited for this purpose.

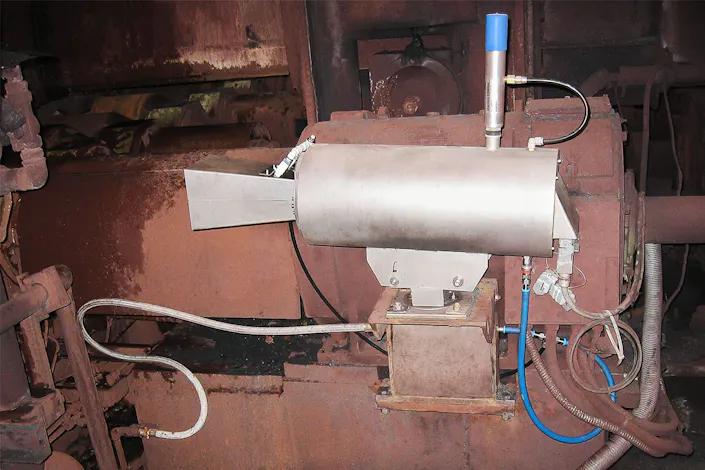

Design of this System Solution

Depending on the requirements, various industrial infrared cameras are available. Built in robust protective housings they can be directly integrated into the machines. These are capable of reliably capturing temperature measurement data even under adverse manufacturing conditions. An adapted control and analysis unit running the INDU-SCAN software and also designed for 24/7 industrial monitoring, is used for both inline thermal process monitoring and storage of the measurement data captured by the cameras. The system itself is connected to machine control for process synchronisation. All recorded thermal data are made available in a higher-level system for analysis and documentation.

The application of thermal imaging thus ensures a high degree of process stability. The result is high productivity and component quality, combined with long-lasting tool durability and low wear on the die casting system.

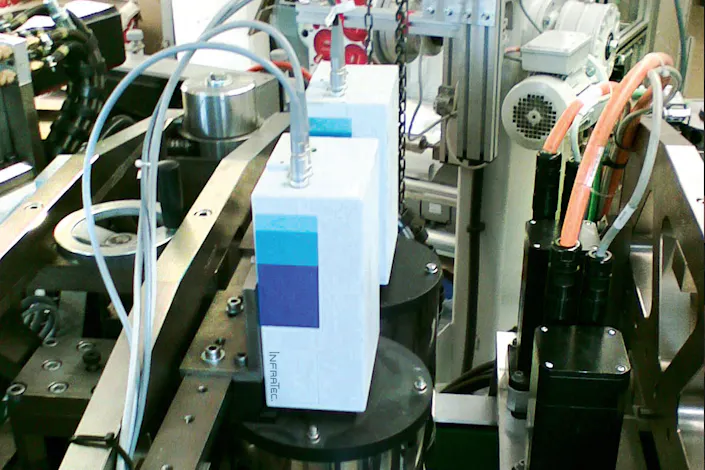

PEEL-SCAN – Checking seals using thermography

Plastic containers sealed with metallic films are often used in the pharmaceutical and food industries. With the PEEL-SCAN automation solution from InfraTec, defects in the seals can be detected, as can poor sealing seams between plastic and metal. Even the smallest defects that cause temperature differences of 20 mK can be detected with thermographic cameras such as the ImageIR® 6300 and visualised using IRBIS® software.

Non-destructive analysis of entire batches

Plastic containers are sealed with foil in the industrial production process fully automatically and at high cycle frequencies. This means that there is very little time available for quality control. Thermal imaging offers the possibility to evaluate the quality of the seal non-destructively in fractions of a second and continuously for each individual container.

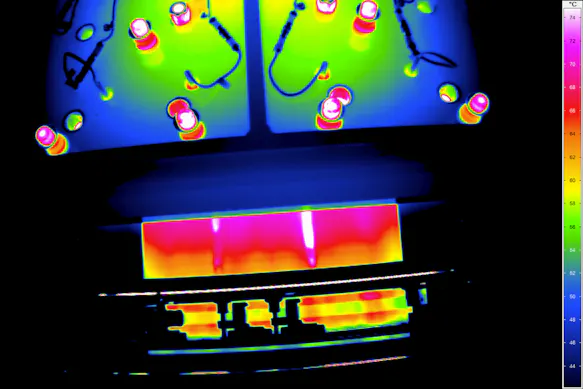

During the sealing process, the sealing film is partially heated. As it melts, it bonds with the container. The quality of the seal can be inspected immediately afterwards, before the film has cooled down completely. The software compares the image captured with that of a flawless seal and uses temperature differences to detect defects in the sealing seams and in the sealing films.

The colours in the thermal image represent different calibrated temperature values. Deviations can be identified quickly and reliably, using analysis algorithms integrated into the thermography software. Containers with seals identified as faulty will be removed from further processing.

Easy to integrate, permanently reliable

For a long time, uncooled infrared cameras were used for checking seals and for similar tasks. However, due to their low frame rates, longer integration times and a line-by-line readout process (rolling shutter) which causes distortions in the imaging and measurement of moving objects, these systems quickly reach their limits.

The ImageIR® 6300 from InfraTec is ideal for monitoring fast processes, even in 24/7 operation. Due to an optimised cooler concept, the cost-effective infrared camera is permanently maintenance-free, even in difficult environments. The lightweight and compact ImageIR® 6300 can be easily integrated into the production line via plug & play and precisely controlled using fast triggers. The data obtained is stored directly on the infrared camera or transmitted uncompressed via Gigabit Ethernet to professional control units.

The benefits of the PEEL-SCAN automation solution with the ImageIR® 6300

Easy-to-integrate, industrial-grade overall solution with compact and affordable infrared camera

Longlife cooler for maintenance-free continuous operation

Excellent geometrical and thermal resolution even at high speeds

Intelligent evaluation with user-friendly software

INDU-SCAN base – Thermography Automation Solution for Industrial Applications

INDU-SCAN base is a scalable, flexible and reasonably priced solution for the monitoring and automation of production processes. The system supports continuous thermographic measurement of temperatures and monitoring of production processes for early detection of faults and their causes. Combining multiple thermography cameras – VarioCAM® HD series or TarisIR® mini – with high-performance InfraTec software and a robust industrial PC, INDU-SCAN base has been designed specifically for continuous use in industrial applications.

Easy to Install and Expand

One of the major advantages of INDU-SCAN base is how easy it is to install. Thanks to a modular design, the system can be expanded at will by adding more cameras or accessories. This offers businesses investment security, because the system can be adapted to meet future requirements.

The experts at InfraTec provide support in the form of comprehensive consultation and are with users at every step of the way, from planning a system configuration to its implementation and beyond to the ideal configuration to meet process requirements.

Major Advantages at a Glance

Modular system: Up to three high-resolution infrared cameras can be used

Value for money: A cost-effective and reliable solution

Durable: High-quality industrially tested components for fault-free operation 24/7

Easy configuration: Separately for camera and control unit

Extensive reporting: Detailed event logs for downstream analysis

Easy configuration: Separately for camera and control unit

TarisIR® mini – Easy to Integrate

The radiometric compact camera is characterised by very low power consumption and can be conveniently supplied with power via Ethernet (POE). Thanks to the individual configurability and extremely small design TarisIR® mini is predestined for use in OEM solutions. It can be easily integrated into machines, systems and devices for monitoring and measuring tasks in process optimisation and quality assurance. The GenICam compatibility and included Software Development Kit (SDK) makes this significantly easier.

The modern interface concept of the TarisIR® mini enables convenient camera control and data acquisition. Recordings can be saved and/or processed on a PC in real time at frame rates of up to 50 Hz via the GigE interface.