Thermography Brake Test Bench and Tyre Test Bench

Thermal Rotate Check (TRC) – IR-rotation Test System

The long-life fatigue strength and wearout are important characteristics of mechanical components. Manufacturers test these with certified procedures. Thermal measuring can be the decisive relief needed for evaluations under stress.

Quick data acquisition with InfraTec's high-end systems

Powerful evaluation software IRBIS® 3 rotate available

Thermal Rotate Check - TRC

Rotational Test Benches Made by InfraTec

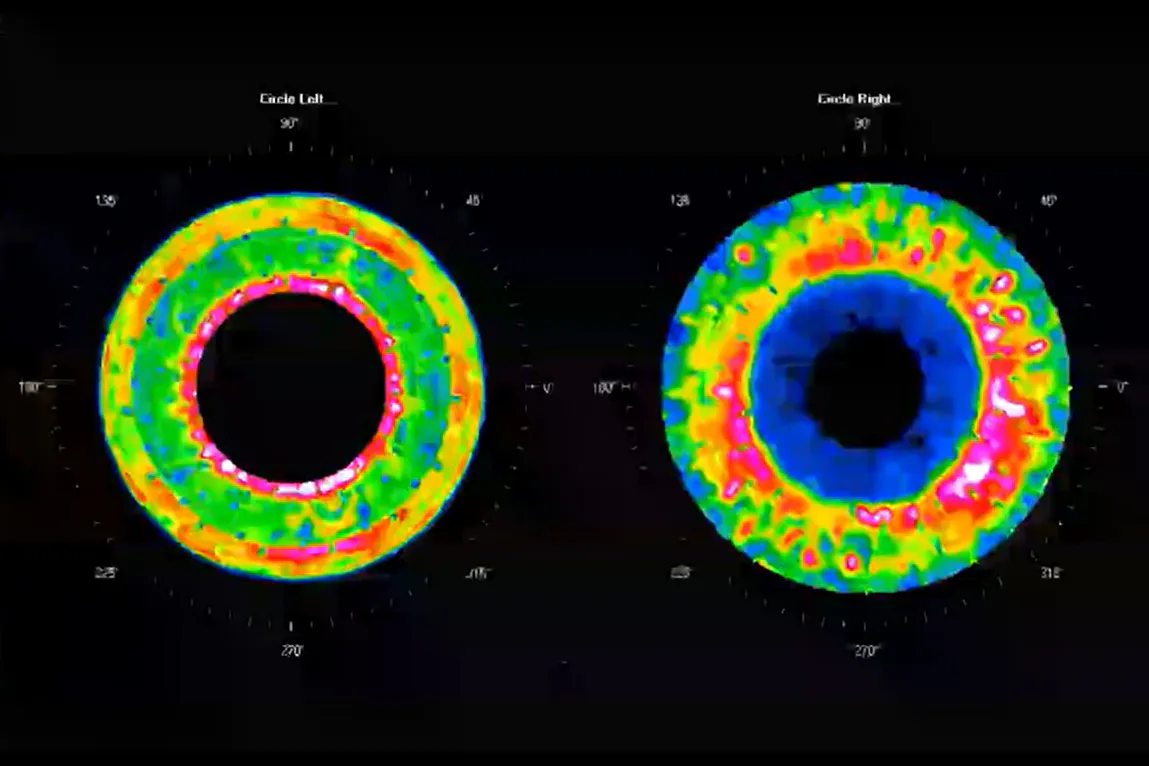

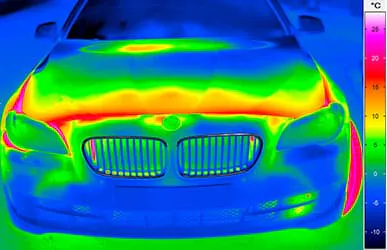

The automotive industry's wearing part requirements concerning lifetime and quality are increasing steadily. To analyse fast rotational parts, such as brakes, tyres and clutches under different load conditions, InfraTec has developed an IR-rotation test system – Thermal Rotate Check (TRC). This can be used, for example, as a brake test bench or as a tyre test bench.

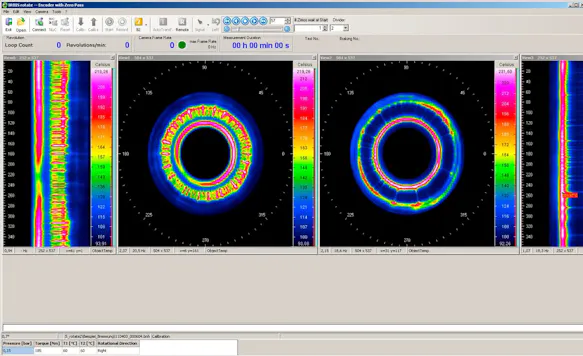

The respective test object will be sampled at sample rates which range up to the kilohertz band. Data acquisition will be triggered automatically by the testing machine. Various transformations can be done to display and archive the thermographic data. The thermography evaluation software IRBIS® 3 rotate is available to analyse the acquired data. According to requirements, integrators can also integrate the entire system into existing production environments.

High-Speed Thermography for Rotating Parts

Existing temperature measurement methods

High-speed thermography TRC mode: Setup

TRC hardware and software

Advantages of TRC mode and sample measurements

High-Speed Thermography for Rotating Parts

Features of the IR Rotation Test System TRC

Synchronized raw-data acquisition double-sided

Automatic hotspot detection

Recording of machine parameters (contact pressure, speed, etc.)

Statistical data preparation

Acquisition parameters can be adjusted and saved

Alarm release when surpassing critical temperature thresholds during live load tests

Flexible configuration depending on measurement and testing task, e.g. as brake test bench, tyre test bench, etc.

Optional integration as OEM solution

Advantages of the Evaluation Software IRBIS® 3 rotate

Contactless online acquisition of thermal state

Automatic detection of thermal abnormal behaviour on the test device

All at once visualization of all thermal active areas

Measurements in various transformation views

System Structure

Cooled high-speed thermographic camera in an industrial protective housing with application-specific calibration

Parameter setting, administration, display, evaluation or playback on PC with the special software IRBIS® 3 rotate

Interface for process signals (trigger input, alarm and measured value output)

Product Flyer

Get all the information you need at a glance in our product flyers

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.