Welding Inspection - WELD-CHECK

WELD-CHECK is a fully automatic system for non-destructive, contactless examination of welded joints of car bodies and sets new standards for testing accuracy and efficiency.

Quality Control and Weld Inspection with WELD-CHECK

Universal use through testing of resistance and laser welded joints (resistance welding spots, laser welding seams, RobScan welding seams)

Increase in efficiency through fully automatic weld testing system with measurement duration of only a few seconds per welding seam or welding spot

Highest weld testing accuracy through evaluation with special software algorithm

Detection and classification of various types of defects as deviations in the joining process at an early stage

Integration into the local quality management by creating test records to be included into databases

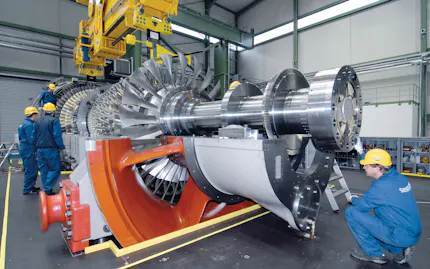

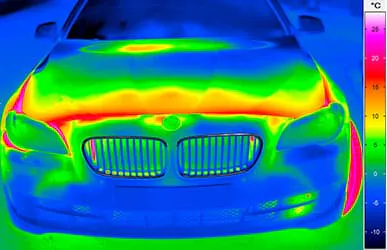

Thermography for Fully-Automated Non-Destructive Testing of Car Bodies

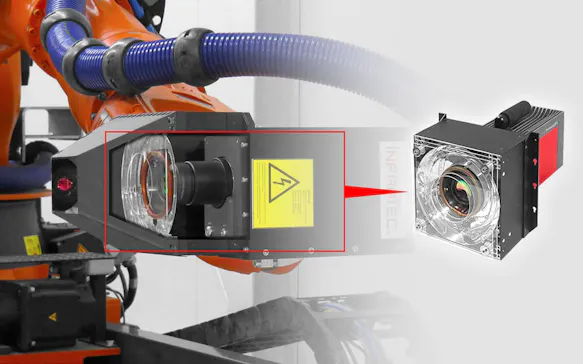

Using pulse thermography, the weld inspection system WELD-CHECK enables you a quantitative assessment of the inspected welds. A special software algorithm analyzes the pulse-induced change in temperature in the tested joint and computes, based on its temporal course and geometric spreading, corresponding test results. These results are documented in a test report and provided in a format that can be used in your quality databases. This makes WELD-CHECK the ideal weld test system for automobile body assembly - both as an offline measuring unit as well as for in-line inspection.

Thermal imaging cameras of the high-end camera series ImageIR® by InfraTec are essential components used in this system. Enabling a geometric resolution of up to (2,560 × 2,048) IR pixels, frame rates with some kHz and thermal resolutions below 0,015 K they provide the precise measurement basis for the reliable detection of even the smallest anomalies.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

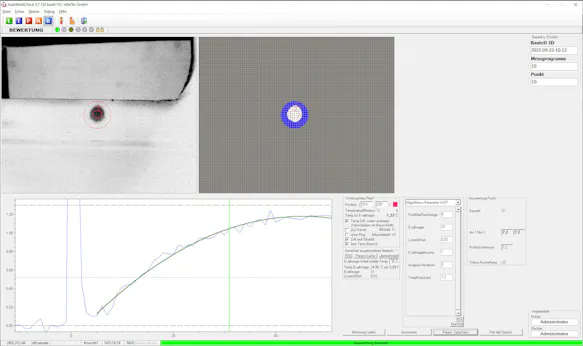

WELD-CHECK Software

Different operating modes for Teach-In, testing and offline analysis

Provision of all relevant information in testing mode with live, difference, evaluation and reference image

Comprehensive representation of results

Offline mode for parameterisation and evaluation of large datasets

Flexible integration into the local system structure via universal interfaces and bus systems

Product Flyer

Get all the information you need at a glance in our product flyers