ImageIR® 10300

With the ImageIR® 10300, users from industry and science can use a radiometric infrared camera whose cooled photon detector permits images in the format (1,920 × 1,536) IR pixels.

Full HD resolution of about 3 Megapixels

Pixel pitch of 10 µm

Thermal resolution better than 0.03 K

Measurement accuracy ± 1 °C or ± 1 %

High-speed recording with excellent image quality

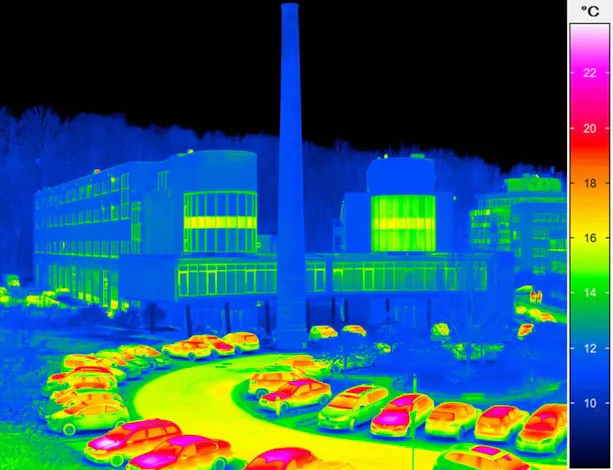

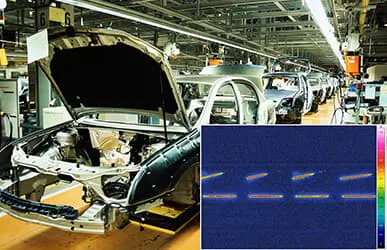

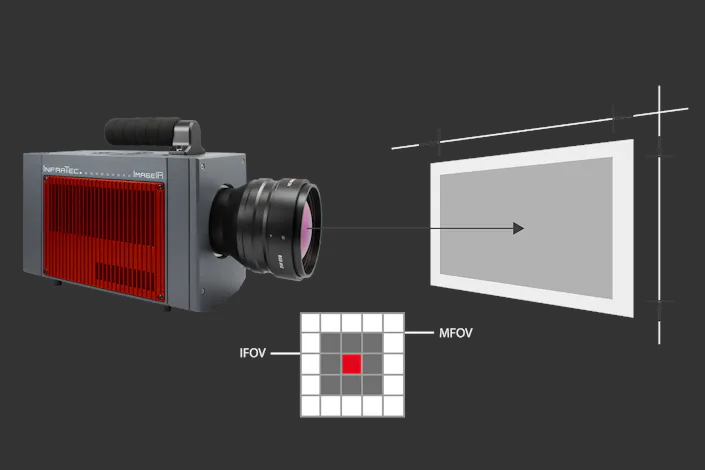

Efficient measurement of smallest structures on large-scale objects

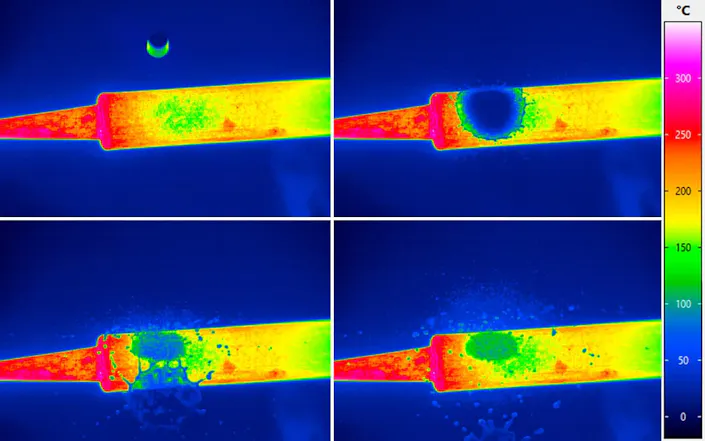

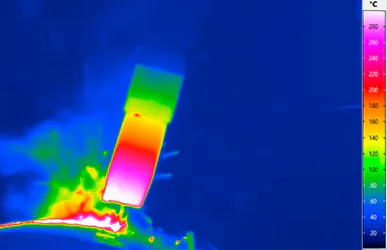

Analysis of extreme temperature changes and gradients

Highly accuracte and repeatable measurements

Precise detection of smallest temperature differences

High-speed, long-distance interference proof data transmission

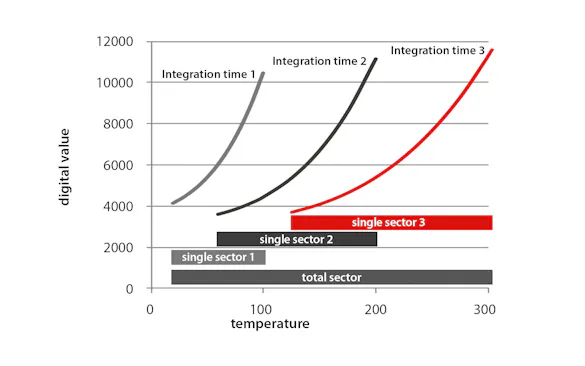

Increases frame rates and thermal resolution at the same time using binning technology

Adaptation of the image geometry to almost every measuring situation

The long-term top model of the ImageIR® series symbolises InfraTec's accumulated knowledge from 25 years of applied thermography. It incorporates the consequence of our own development efforts, which strive consistently for perfection. And it reflects the skills of experienced engineers, who check each component's suitability to produce in the end a precise high-tech measurement instrument.

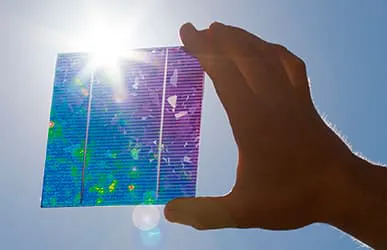

The ImageIR® 10300 with its high geometric resolution marks the current highpoint of the high-end camera series produced in Dresden. The detector format, in combination with the small pitch dimension of 10 µm, ensures that measurement, inspection and surveillance tasks can be solved even more efficiently than before. Everywhere that very fine structures need to be analysed on large-surface measurement objects, for example, users save time, effort and thus costs.

Always Stay Flexible with the Modular System

Like the entire high-end camera series, the ImageIR® 10300 is also made up of several modules. This simplifies individual adaptation to your demands. Numerous components can be retrofitted even after the original configuration is established. The modular design likewise includes the camera housing. Produced from high-strength aluminium, it is suited for use under rough environmental conditions due to its compact dimensions and low weight. The interfaces are equipped with industrial plug connectors that maintain the protection degree.

InfraTec ImageIR® high-end infrared camera series

Master the Most Complex Measurement and Inspection Tasks Yourself

High object temperatures or specific material characteristics of the measurement objects can make analysis with thermographic systems considerably more challenging. For such cases, InfraTec offers equipment with an optional aperture wheel and filter wheel. It is motorised and can be operated through the camera controller.

For example, if extremely high temperatures on objects are measured, the apertures weaken the respective radiation accordingly. With calibrated measurement ranges, a previously determined aperture is automatically selected and used for image recording.

If specific emission or transmission characteristics of the measurement object make the task more difficult, users can equip the aperture wheel and filter wheel of ImageIR® with filters. As a result, the camera's range of use is expanded to cover the area of spectral thermography. In this way, transmission is prevented with thin foils and only their purely emitted radiation is recorded for temperature measurement. The wheel offers room for up to five spectral filters or apertures, so the thermography system can be adapted to target the measurement and inspection task on site.

10 GigE Interface for a Strong Increase in Output

The new 1 Gigabit Ethernet interface of the high-end camera series ImageIR® opens this extremely fast transmission standard with a NIC specially developed by InfraTec. This works with optical or electrical transceiver modules that are easy to change and are called SFP+. For all models of the ImageIR® 8300 hp with their (640 × 480) IR pixel detectors this leads to a transfer rate in the full frame mode up to 355 Hz. Users can store large quantities of data to a computer easily and reliably.

Different 10 GigE fiber SFP+ transceivers allow transmission ranges of up to ten kilometers with the same low sensitivity to electromagnetic interference. A corresponding standard SFP ensures backward compatibility with the conventional GigE interface. This combination allows the ease of use of the cameras with the new 10 Gigabit Ethernet interface in existing systems - though at a reduced transmission rate.

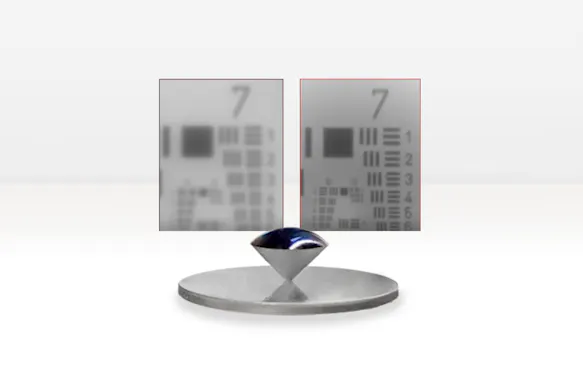

Solid Immersion Lens (SIL) for ImageIR®

In order to make particularly small structures clearly visible, an infrared camera with a large detector format is suitable. In some cases, special measurement and testing tasks require a further increase in spatial resolution. In the field of micro-thermography, high-performance infrared microscopic lenses are used for this purpose. Their benefits can be further increased in conjunction with Solid Immersion Lenses (SIL). Mounted on the optics, these immersion media significantly improve the resolution of even the smallest structures in the µm range.

Technical Specifications

| Spectral range | (3.6 … 4.9) μm |

| Pitch | 10 µm |

| Detector | InSb |

| Detector format (IR pixels) | (1,920 × 1,536) |

| Image recording principle | Snapshot |

| Readout mode | ITR / IWR |

| Aperture ratio | f/2.0 |

| Detector cooling | Stirling cooler |

| Temperature measuring range | (-40 … 1,200) °C, up to 3,000 °C* |

| Measurement accuracy | ± 1 °C or ± 1 % |

| Temperature resolution at 30 °C | Better than 0.035 K / 0.022 K in high-speed mode |

| Frame rate (full / half / quarter / sub frame) | Up to 113 / 216 / 396 / 1,915 Hz High-speed mode: up to 400 / 692 / 1,088 / 2,493 Hz |

| Window mode | Yes |

* Depending on model

** In selected measurement ranges

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

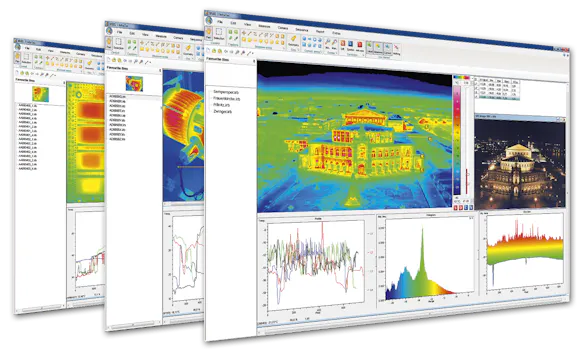

Comprehensive Thermography Evaluation Software for Efficient Operation

The software family IRBIS® 3, which was developed by InfraTec, is part of a complete system of the camera series ImageIR®. The comfortable and professional thermography software IRBIS® 3 professional offers a wide range of analysis- and editing tools to analyse sophisticated thermal investigations. The combination of ImageIR® together with the professional thermographic software meets all requirements that are set as standard for efficient high-performance tools for thermographic investigations.

Product Flyer

Get all the information you need at a glance in our product flyers

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.