Quality Assurance for the Coating of Metal Sheets, Foils, Glass and other Materials

Detecting defective coatings with an infrared camera has many advantages

In-line and offline process control avoids costly rejects

Non-destructive and automated monitoring of coating quality

Flexible adaptation to different measurement tasks (recipes, belt speed)

Integration into existing process and system environments

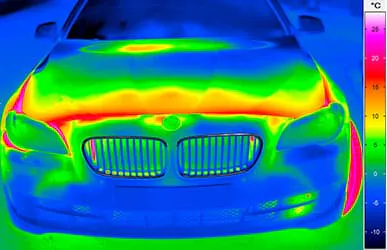

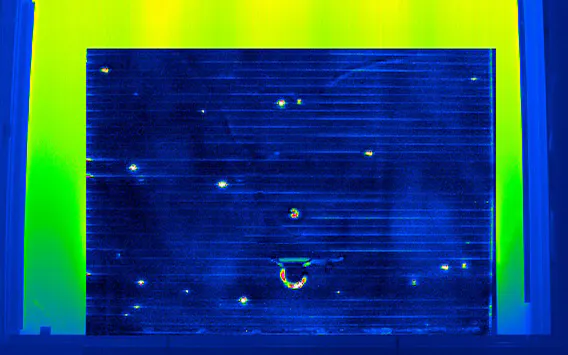

Surface coating of metal sheets, foils, glass or even plastics effectively protects them from external influences, prevents corrosion and wear, and increases scratch resistance, for example. Using infrared cameras and active excitation – for example with the reflectography method – allows non-destructive and process-synchronous monitoring to ensure that these coatings are free of defects as soon as they are applied.

In the process, it is possible, for example, to test the homogeneity and quantity of liquid coatings such as water, oil and adhesive coatings. Furthermore, the properties of various functional coatings made of metals, semiconductors, dielectrics, organic and nanomaterials can be tested by means of thermography.

LayIR-CHECK: Automated Solution for Testing

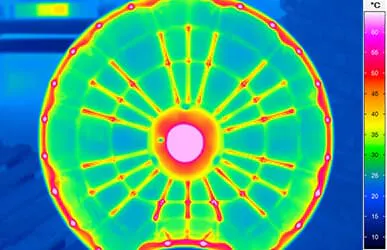

The LayIR-CHECK system for reflectography consists of one or more cooled infrared cameras of the ImageIR® series with special lens and plant-specific installation design, for example with extra water cooling, modified connection units and a control cabinet. The application-specific INDU-SCAN software developed in-house by InfraTec controls the LayIR-CHECK system, processes the measurement data and generates the test results.

InfraTec supplies the thermographic inspection system as a complete solution consisting of consulting, design, installation and commissioning. The installation of the system components takes place directly in the existing plant and enables the direct integration into internal processes, which ensures an efficient and permanently operational inline inspection. Flexible, industrial-grade cabling technology ensures the connection of the infrared camera. The camera can be equipped with task-specific spectral filters via an integrated filter wheel, so that its sensitivity range is precisely matched to the spectral properties of the coating to be detected.

Detecting Defective Coatings using Infrared Cameras

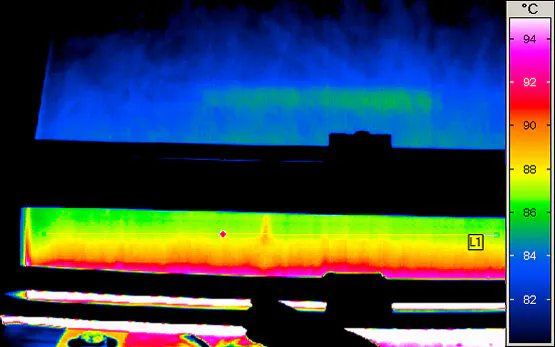

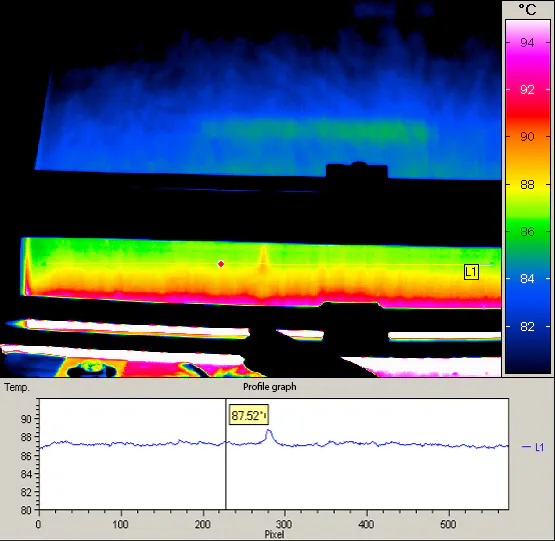

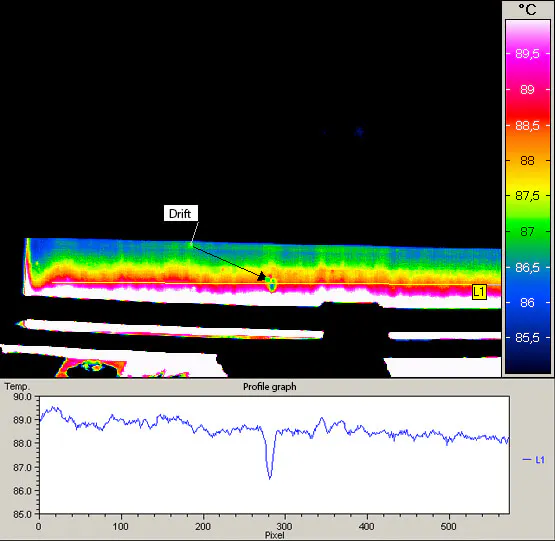

LayIR-CHECK is an automated solution to inspect the surface coating of sheet metal or other materials. Based on information about the layer thickness, coating defects with a diameter of up to approx. 1 millimetre can be efficiently identified. The system alerts immediately and automatically initiates or requests process interventions. Machine parameters can thus be readjusted immediately and production continues optimally.

Measurement as well as storage, evaluation and comparison of measurement data are carried out with a powerful thermographic special software based on the INDU-SCAN modular system. This software allows a very flexible response to daily changing inspection tasks - characterised by changes in types and recipes as well as different belt speeds.

The thermography-based characterisation of coatings by means of reflectography is a special procedure whose high specificity is largely determined by the materials involved in the process. Specially developed emitter units with tailored spectral properties are used for this purpose. Their thermal radiation is in turn reflected spectrally differentiated on the surface of the test object and recorded by the infrared camera. The intensity of this reflected radiation then allows the desired conclusions to be drawn about the coating process. Thus, the method is part of active and spectral thermography. This form of measurement not only allows conclusions to be drawn about upstream processes, but it also permanently characterises the quality of the coating online. This makes it possible to monitor production, with the findings of which the product quality can be raised to the next level.

Advantages over other Test Methods

The inspection is fully automated, online, direct and above all non-destructive. Fully integrated into existing processes and system environments, it avoids costly final inspections and rejects. The automated system can be operated in very fast subframe modes for very fast processes, such as strip processes. Here, the highest sampling rates are combined with the highest geometric resolution. In addition it can be flexible adapted to different measurement tasks (recipes, belt speed).

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.