ImageIR® 8300 hs

High-speed thermography with full resolution

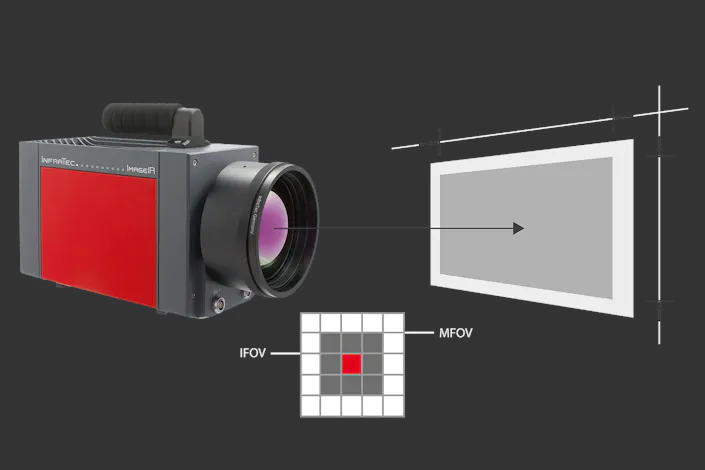

Detection of small details by detector with (640 × 512) R pixels

High thermal resolution of better than 20 mK for precision measurements

High frame rate of 1,105 Hz enables thermographic images of extremely fast moving objects or highly dynamic thermal processes

Pixel pitch of 25 µm allows shortest integration times and extremely high frame rates

Large detector enables highest sensivity

Analysis of extreme temperature changes and gradients in full frame

Highly accurate and repeatable measurements

Precise detection of smallest temperature differences

High-speed, long-distance interference proof data transmission

Precise measurement of low temperatures and very fast integration times

High-speed Thermography in Full Resolution

Measurement of Fast Processes Combined with Highest Precision

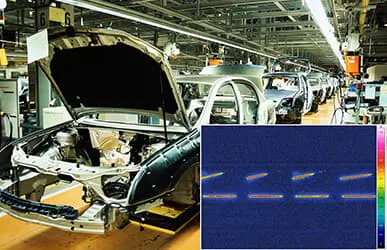

Combining the image format of (640 × 512) IR pixels with the exceptionally high frame rate of 1,105 Hz allows thermographic images, even of extremely fast moving objects or highly dynamic thermal processes. Thus, exactly the moment that matters is captured with absolute precision, displayed with high resolution and precisely measured thermally.

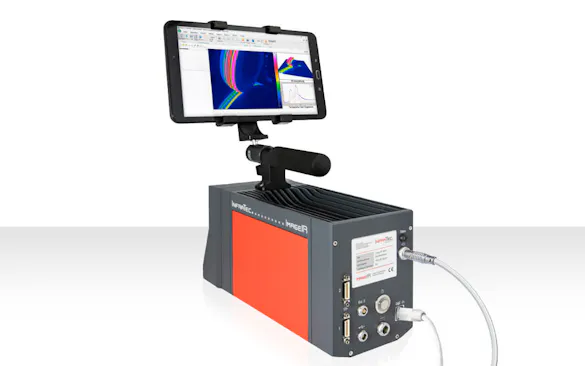

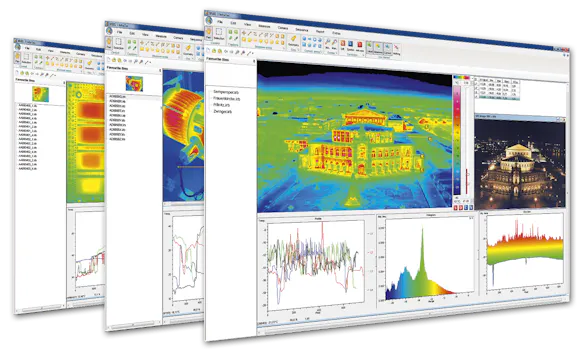

Due to the latest detector technology, this camera – sensitive in the mid-infrared – allows high-speed thermography in full frame format and achieves a high thermal resolution of 20 mK. The radiometric image data are transferred with loss-free intelligent real-time compression - without having to use internal memory – directly via an industrial 10 GigE interface to a standard notebook for storage, control and analysis. The digital high-speed data acquisition is carried out with InfraTec's IRBIS® 3 thermography software family.

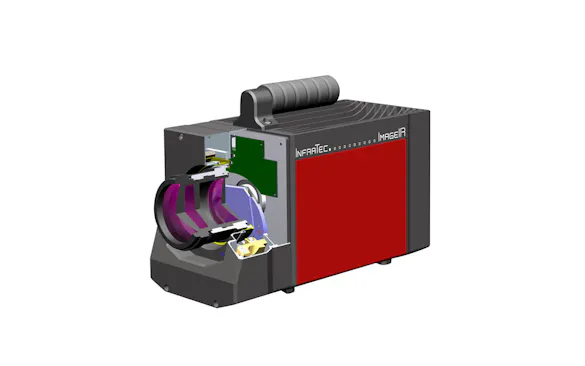

Use of the Latest Detector Technology for Longer Service Life

The ImageIR® 8300 hs is based on an innovative detector: T2SLS with HOT long-life technology. This offers an excellent signal-to-noise ratio starting at relatively high operating temperatures of about 130 K resulting in lower wear and tear on the cooling system. Thus, this thermographic camera requires significantly lower cooling capacity than conventional models, which typically operate at 77 K. This results in less stress on the integrated Stirling cooler, which in turn increases the lifetime of the camera compared to other cooled cameras.

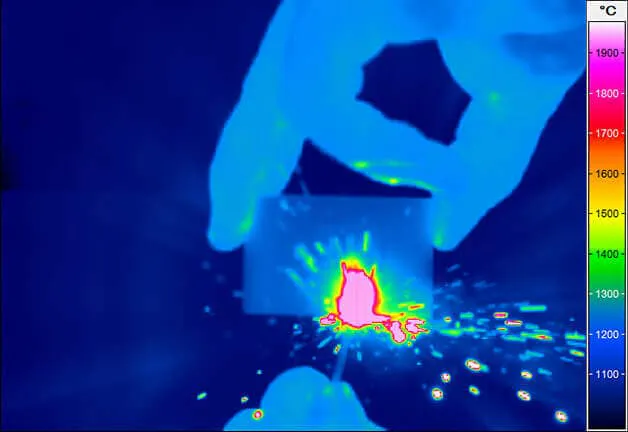

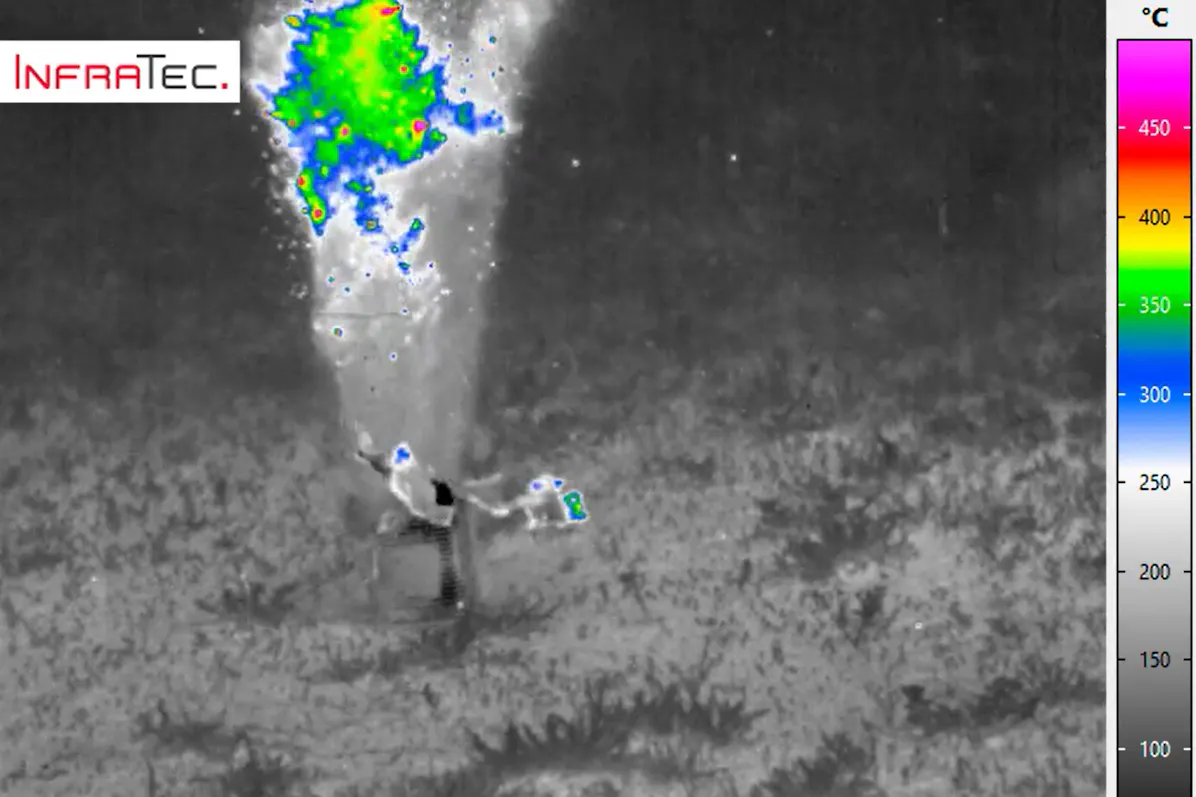

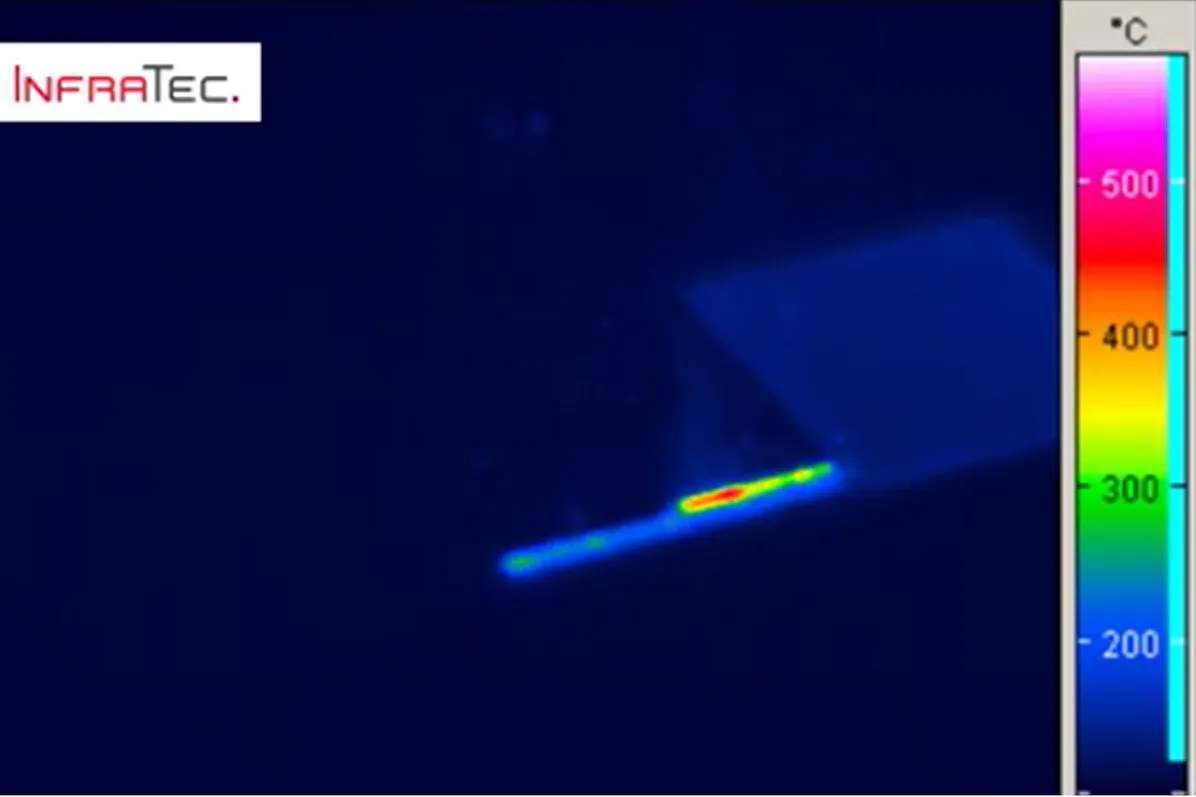

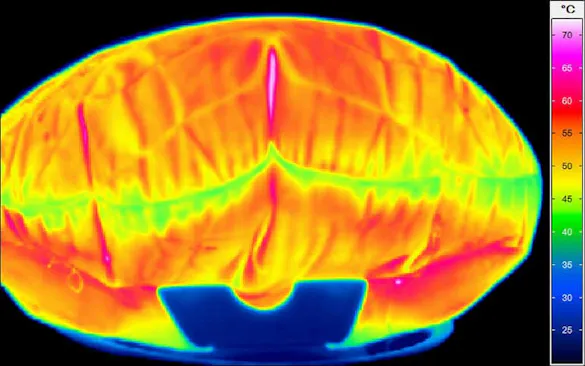

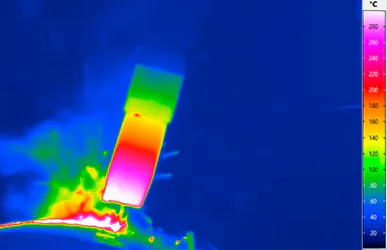

Capture Fast Processes with Large Temperature Differences with High Precision

The camera's wide temperature measurement range allows fast processes with large temperature gradients, such as those occurring in explosions, electrical discharges or laser machining processes, to be easily recorded. The new ImageIR® 8300 hs can be equipped with a fast rotating filter wheel to adapt the camera sensitivity to the spectral properties of the target. Equipped with up to six spectral filters, the filter wheel allows sequential measurements of high image frequency in different spectral ranges.

Thermographic Video of fast Processes

Increase Your Flexibility by Using the Modular Design Concept

The ImageIR® series is based on a modular concept and allows for successive upgrading and changes of powerful components like motorized lenses or a high-speed shutter. Already in its basic configuration it can be delivered with different detectors which support your application the best way. Like this you will always remain flexible and optimally adapt your camera systems to your respective needs.

Measure Precisely Over a Long Time

A high long-term stability of the thermographic measurement with infrared camera systems of the ImageIR® 8300 hs series is achieved by an excellent thermal decoupling of the electronics module which will emit heat during its operation from the optical and detector module being most important for the signal receipt.

Detect Smallest Temperature Differences Using High Thermal Resolution of 20 mK

The thermal resolution of the ImageIR® infrared camera series allows you to measure smallest temperature differences of (at 30 °C). Thermal images with a narrow temperature span display details absolutely sharp. You will find interesting signatures even there where other infrared camera systems cannot detect any temperature differences any longer.

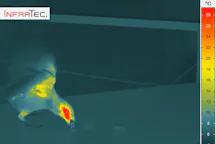

Acquire Thermal Images in a Millisecond of Time

The exact and fast control of the detectors of the ImageIR® 8300 hs series provides the possibility to acquire and analyse thermal images at a time scale of milliseconds. Thereby it allows an easy analysis of fast processes regarding their thermal changes. Thermal images can be stored at a frame rate of up to 30,000 Hz and provide insights into thermal changes of fast running processes.

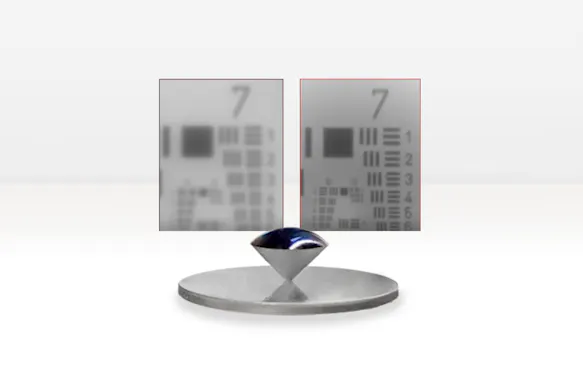

Solid Immersion Lens (SIL) for ImageIR®

In order to make particularly small structures clearly visible, an infrared camera with a large detector format is suitable. In some cases, special measurement and testing tasks require a further increase in spatial resolution. In the field of micro-thermography, high-performance infrared microscopic lenses are used for this purpose. Their benefits can be further increased in conjunction with Solid Immersion Lenses (SIL). Mounted on the optics, these immersion media significantly improve the resolution of even the smallest structures in the µm range.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Technical Specifications

| Spectral range | InSb: (1.5 ... 5.5) µm; T2SLS: (1.5 … 6) µm |

| Pitch | 25 µm |

| Detector | T2SLS or InSb |

| Detector format (IR pixels) | (640 x 512) |

| Image recording principle | Snapshot |

| Readout mode | IWR |

| Aperture ratio | f/2.0 |

| Detector cooling | Stirling cooler; HOT Long-Life (T2SLS) |

| Temperature measuring range | (-40 … 1,700) °C, up to 3,000 °C* |

| Measurement accuracy | ± 1 °C or ± 1 % |

| Temperature resolution at 30 °C | Better than 0.02 K |

| Frame rate (full / half / quarter / sub frame) | Up to 1,105/1,957/3,731/30,330 Hz |

| Window mode | Yes |

* Depending on model

** In selected measurement ranges

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

Comprehensive Thermography Evaluation Software for Efficient Operation

The software family IRBIS® 3, which was developed by InfraTec, is part of a complete system of the camera series ImageIR®. The comfortable and professional thermography software IRBIS® 3 professional offers a wide range of analysis- and editing tools to analyse sophisticated thermal investigations. The combination of ImageIR® together with the professional thermographic software meets all requirements that are set as standard for efficient high-performance tools for thermographic investigations.

Product Flyer

Get all the information you need at a glance in our product flyers

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.