ImageIR® 8300

The most solid all-rounder of the cooled infrared camera systems

Detection of small details with detector of (640 × 512) IR pixels

High thermal resolution better than 20 mK for precision measurements

Snapshot detector for precise image acquisition at frame rates up to 205 kHz in full frame

Motorised focus unit enabling precise, remotely controlled and fast focusing

Large detector enables highest sensivity

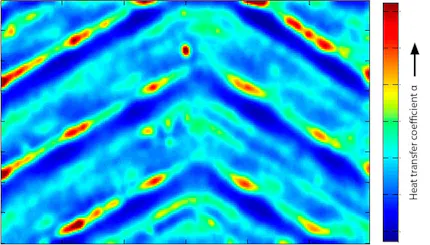

Analysis of extreme temperature changes and gradients in full frame

Highly accurate and repeatable measurements

Precise detection of smallest temperature differences

Enables measurement tasks with high object temperatures and spectral thermography

Precise, fast and remotely controllable; including multiple autofocus functions

Highly precise repeatable data recording; time- and event-controlled

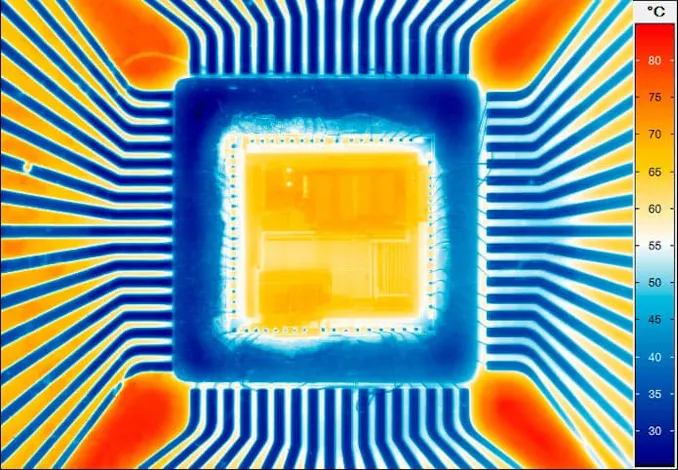

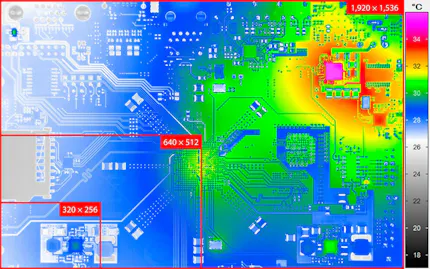

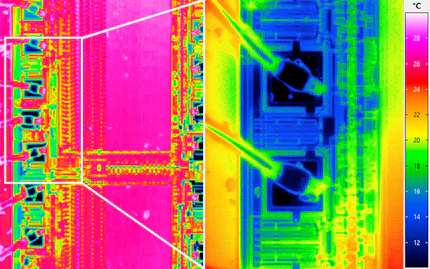

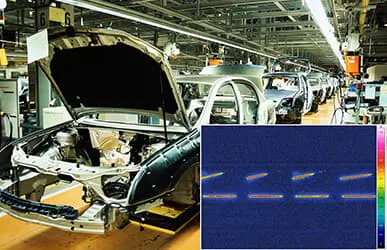

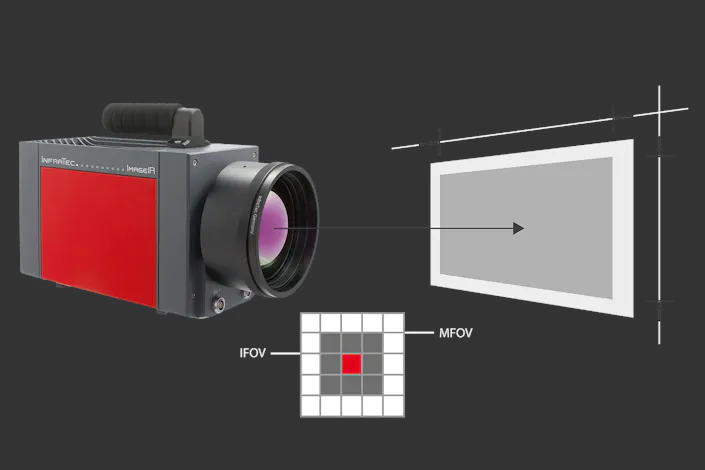

Avoid Measurement Errors Using Highest Geometrical Resolution of (640 × 512) Infrared Pixels

Compared with digital camera systems operating in the visible spectrum thermographic detector technologies still suffer from lower pixel numbers. Therefore every pixel counts as in former times of digital photography. This ImageIR® infrared camera series offers you (640 × 512) IR pixels of the high-resolution detector.

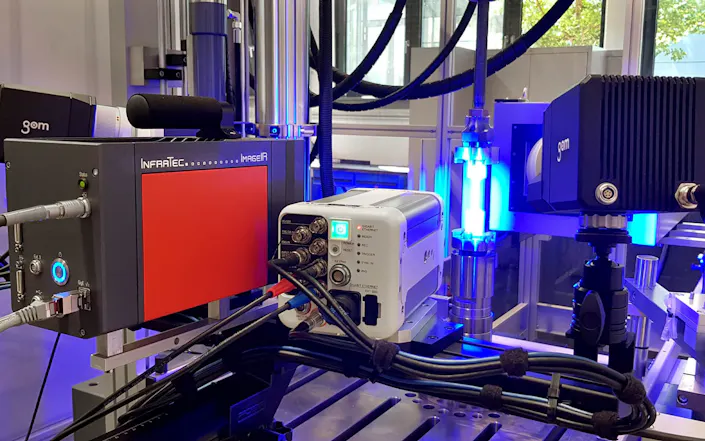

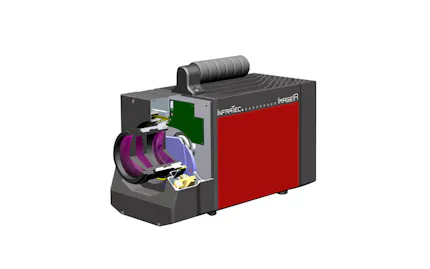

Increase Your Flexibility by Using the Modular Design Concept

The ImageIR® series is based on a modular concept and allows for successive upgrading and changes of powerful components like motorized lenses or a high-speed shutter. Already in its basic configuration it can be delivered with different detectors which support your application the best way. Like this you will always remain flexible and optimally adapt your camera systems to your respective needs.

Measure Precisely Over a Long Time

A high long-term stability of the thermographic measurement with infrared camera systems of the ImageIR® 8300 hs series is achieved by an excellent thermal decoupling of the electronics module which will emit heat during its operation from the optical and detector module being most important for the signal receipt.

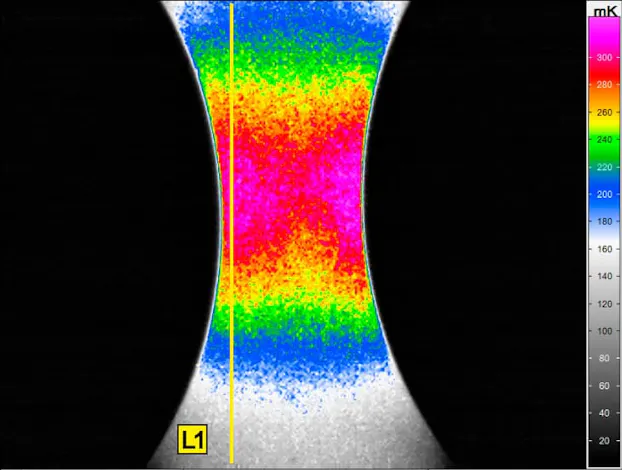

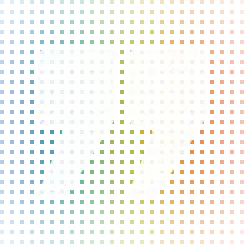

Detect Smallest Temperature Differences Using High Thermal Resolution of 20 mK

The thermal resolution of the ImageIR® infrared camera series allows you to measure smallest temperature differences of (at 30 °C). Thermal images with a narrow temperature span display details absolutely sharp. You will find interesting signatures even there where other infrared camera systems cannot detect any temperature differences any longer.

Acquire Thermal Images in a Millisecond of Time

The exact and fast control of the detectors of the ImageIR® 8300 hs series provides the possibility to acquire and analyse thermal images at a time scale of milliseconds. Thereby it allows an easy analysis of fast processes regarding their thermal changes. Thermal images can be stored at a frame rate of up to 30,000 Hz and provide insights into thermal changes of fast running processes.

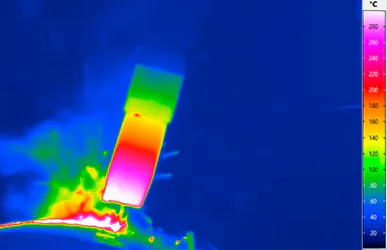

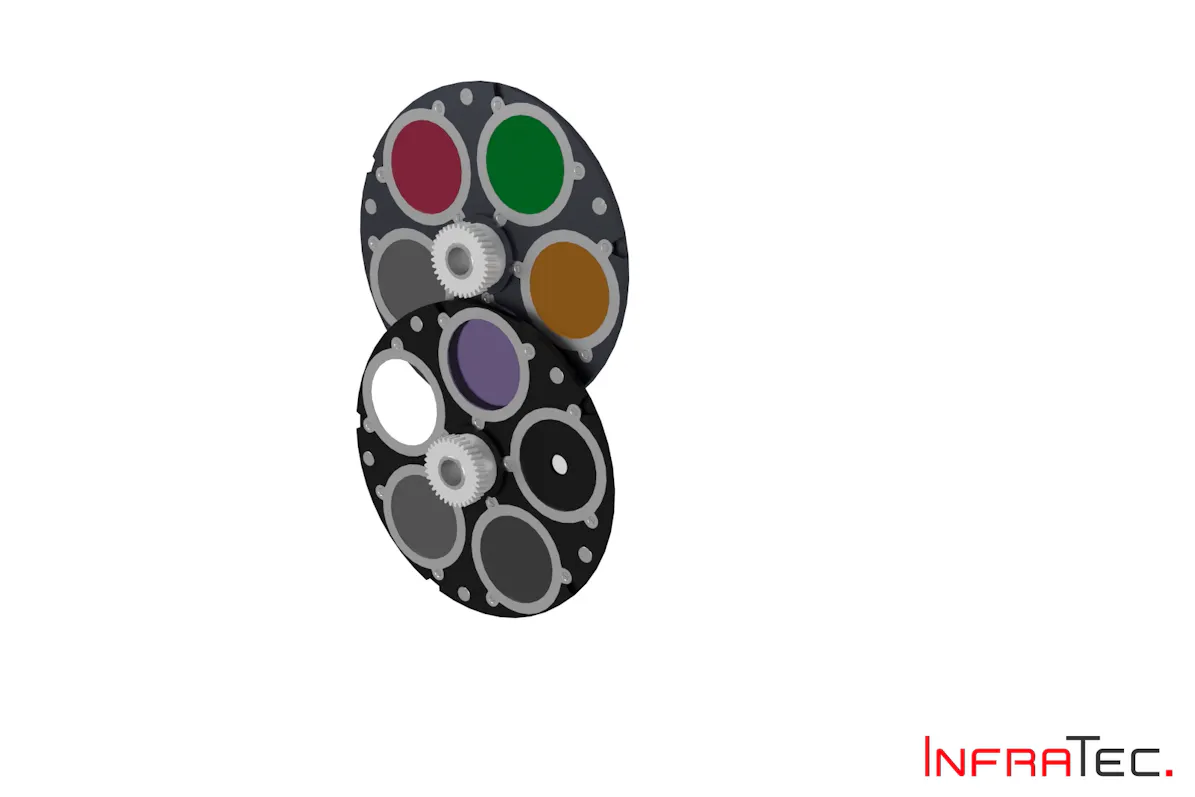

Make Use of Spectral Filters for Material Specific Measurements

Material specific emissivity and transmissivity properties have to be taken into account while measuring with infrared camera systems. The integration of spectral filters makes use of those specifics for special measurements. For example, spectral ranges of thin PE foils can be excluded in case they are highly transmissive – to say transparent. Like this only the radiation will be measured which is purely emitted by the foil itself. Based on its long experience in thermography InfraTec can support you in selecting the right spectral filter. The infrared camera systems of the ImageIR® series can integrate a remotely controllable filter wheel which can hold up to four spectral filters. The filter position close to the detector can avoid warm aperture effects and allows for the usage of smaller and thereby cheaper filters in the infrared camera.

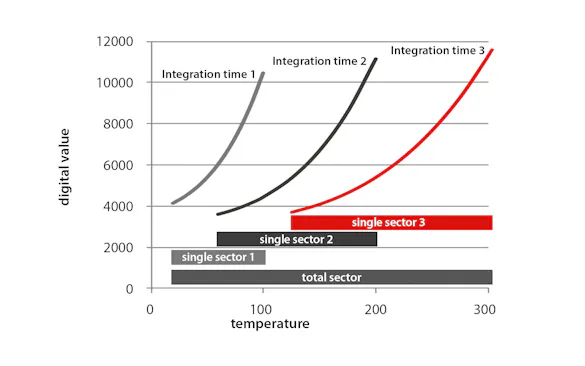

Extend Your Temperature Measurement Range with an Automatic Aperture Setting

The temperature measurement range of the ImageIR® infrared camera series can be widened by an integrated aperture wheel. The motorized aperture wheel can be controlled by the camera control itself. Working with calibrated measurement ranges the appropriate aperture will even be automatically set in the infrared camera. When filter and aperture wheels are separately integrated ImageIR® camera series will be especially flexible in handling specific measurement situations.

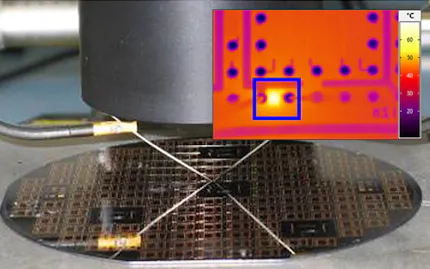

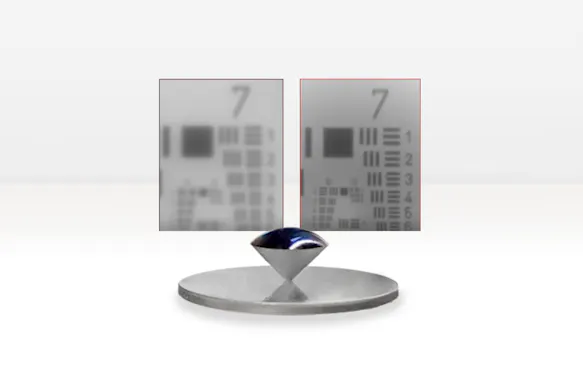

Solid Immersion Lens (SIL) for ImageIR®

In order to make particularly small structures clearly visible, an infrared camera with a large detector format is suitable. In some cases, special measurement and testing tasks require a further increase in spatial resolution. In the field of micro-thermography, high-performance infrared microscopic lenses are used for this purpose. Their benefits can be further increased in conjunction with Solid Immersion Lenses (SIL). Mounted on the optics, these immersion media significantly improve the resolution of even the smallest structures in the µm range.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Technical Specifications

| Spectral range | MCT: (1.5 ... 5.5) µm; InSb: (1.5 ... 5.7) µm |

| Pitch | 15 µm |

| Detector | MCT or InSb |

| Detector format (IR pixels) | (640 × 512) |

| Image recording principle | Snapshot |

| Readout mode | ITR / IWR |

| Aperture ratio | f/3.0 or f/2.0 |

| Detector cooling | Stirling cooler |

| Temperature measuring range | (-40 … 1,500) °C, up to 3,000 °C* |

| Measurement accuracy | ± 1 °C or ± 1 % |

| Temperature resolution at 30 °C | MCT: Better than 0.02 K; InSb: Better than 0.025 K |

| Frame rate (full / half / quarter / sub frame) | MCT: Up to 151/540/1,520/2,807 Hz; InSb: Up to 205/570/1,020/5,000 Hz |

| Window mode | Yes |

* Depending on model

** In selected measurement ranges

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

Statements of our Customers

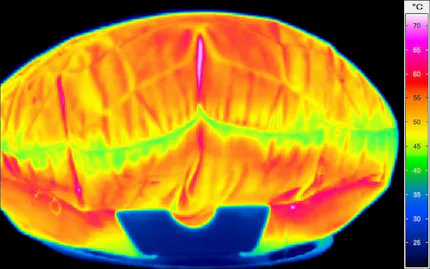

The Bremen Institute for Metrology, Automation and Quality Science (BIMAQ) looks back on many years of intensive cooperation with InfraTec GmbH. In a multitude of scientific and industrial projects, BIMAQ has found a trustworthy and reliable partner in InfraTec GmbH. Especially the powerful thermographic systems of the ImageIR® series enable worldwide novel insights into the real flow behavior of wind turbines at the physical limits of what can be measured. With these insights, a social contribution to climate protection and the provision of clean energy is made. The BIMAQ congratulates InfraTec Gmbh on its long-term success and 30 years of company history and looks forward to further successful cooperation in the future.

As a former student InfraTec employee, who was able to learn a lot and at the same time experience the 10th company anniversary from the first row, I also personally congratulate very cordially!

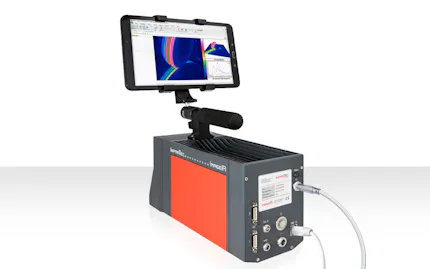

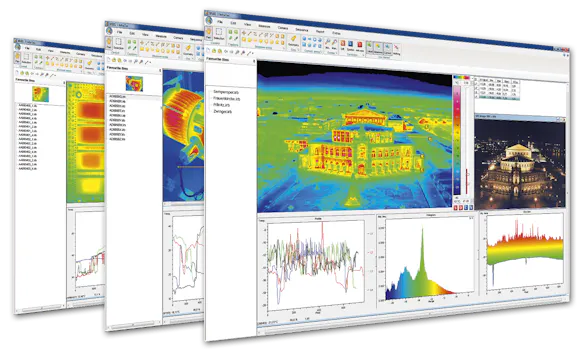

Comprehensive Thermography Evaluation Software for Efficient Operation

The software family IRBIS® 3, which was developed by InfraTec, is part of a complete system of the camera series ImageIR®. The comfortable and professional thermography software IRBIS® 3 professional offers a wide range of analysis- and editing tools to analyse sophisticated thermal investigations. The combination of ImageIR® together with the professional thermographic software meets all requirements that are set as standard for efficient high-performance tools for thermographic investigations.

Product Flyer

Get all the information you need at a glance in our product flyers

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.