GRID-DETECT – Monitoring System

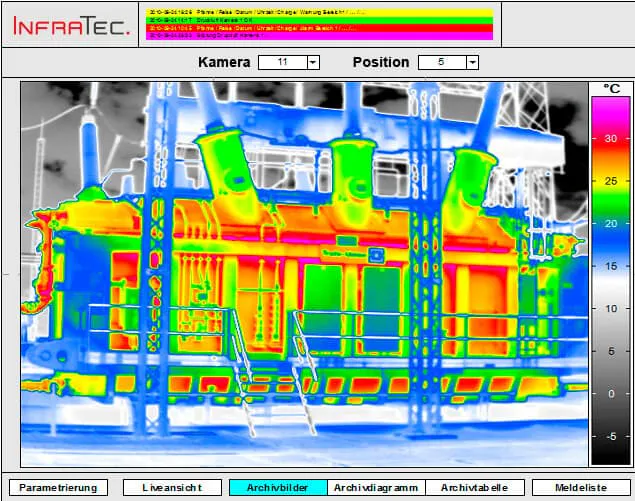

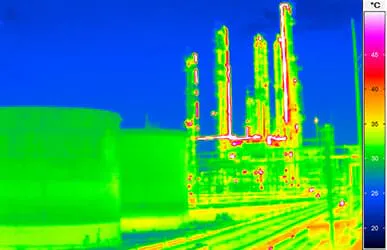

The IR Substation Monitoring System GRID-DETECT uses infrared (IR) technology to monitor the temperature of substation components to secure the reliability of substation. Thermography cameras in combination with visible cameras and pan-tilt head observe the substation area and thus allow predictive maintenance.

The temperature measurements are made fully automatically without the need of any manual interaction. The system GRID-DETECT automatically raises a warning and alarm if an adjustable temperature threshold is passed. This prevents dangerous substation component failures and saves the reliability of the entire substation. GRID-DETECT automatically tracks the temperature development of different substation elements. This allows reducing maintenance costs, failures and unplanned outage of substation. GRID-DETECT comes with highly reliable components in a flexible structure and thus, is easily adaptable to the different situations and operational modes in substations.

System Features

Full automatic operation

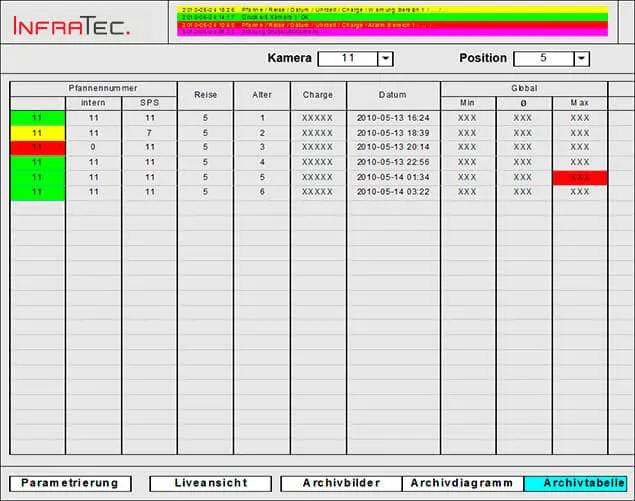

Reliable alarm release at defined pre- and main alarm limits

Merging of IR- and VIS-image for better orientation

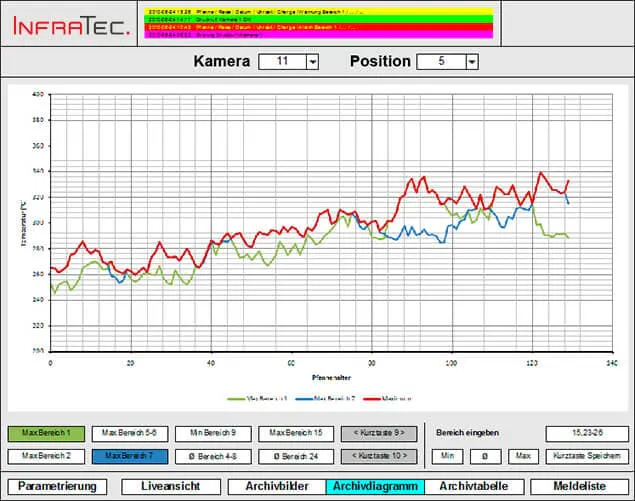

Temperature trend recording and analysis

Customized system alignment and adjustment

Parameterization, supervision, operation, display, evaluation and playback in the GRID-DETECT software

Decentralized monitoring of system status and measured values

Recall of all recorded data for comparison and optimisation

Easy to operate data presentation in the substation network

Remote access from Master Control Center

Benefits of the System

Complete automatic thermographic temperature screening of substation on 24/7 basis

Early detection of equipment failures with maximum range and highest resolution (640 × 480) / (1,280 × 960) IR pixels

Reduction of maintenance costs, failures and outage of substation

Saves investments and long term operating ability of your substation

Flexible structure for customized adaption to your operational modes

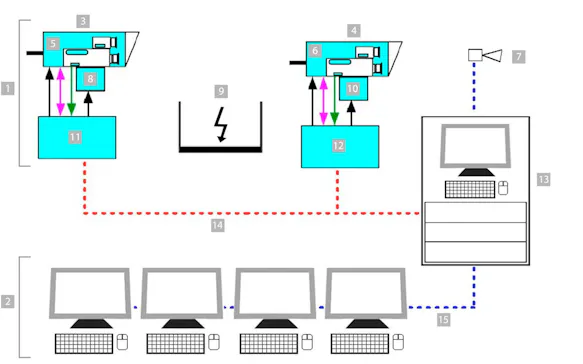

System Structure GRID-DETECT

IR cameras + VIS cameras built in protective housing on pan-tilt head with junction box

Parameterization, supervision, operation, display, evaluation and playback on standard PC at different sites and levels

System 1

System n

Camera

Camera

Buzzer

RTH

Substation

RTH

Junction box

Junction box

19" main cabinet

TCP / IP

TCP / IP

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Construction / Design

Reliable 19"-industrial standard main cabinet

Protective housing and pan-tilt head designed to withstand the harsh environmental conditions

Infrared cameras VarioCAM® HD head and VarioCAM® HDx head with (640 × 480) / (1,280 × 960) IR pixels guarantee long-term exact and reliable temperature measurements

Nearly maintenance-free, no wearing parts

Decentralized installable components (IR cameras, VIS- cameras, PC, alarm unit), fiber optic cable for interference-free data transmission

TCP / IP based flexible structure allows customized adaption to the specific substation situations

Easy to use GRID-DETECT software allows flexible customization

Easy to use GRID-DETECT Software Allows Flexible Customization

Product Flyer

Get all the information you need at a glance in our product flyers