Thermography in Chemical Industry

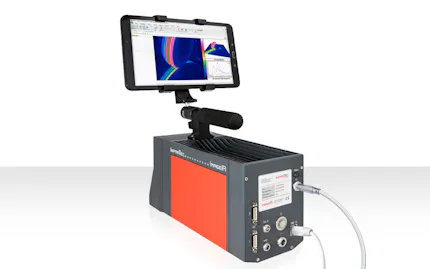

The high-quality infrared cameras from InfraTec provide more efficient values for the various applications in chemical companies.

Contactless temperature measurement of chemical processes

Insulation testing of reactors

Liquid level monitoring of tanks by applying infrared camera systems

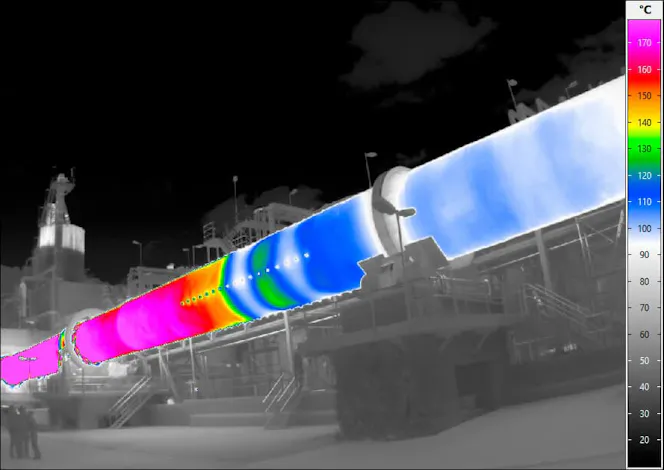

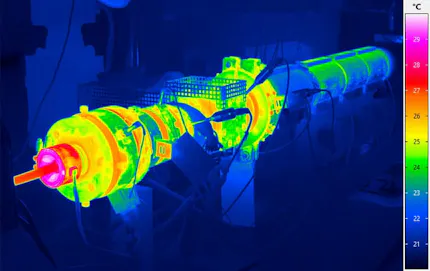

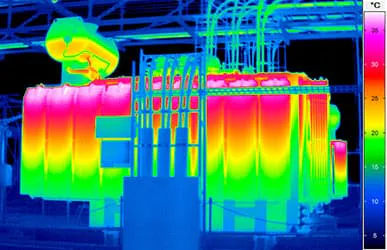

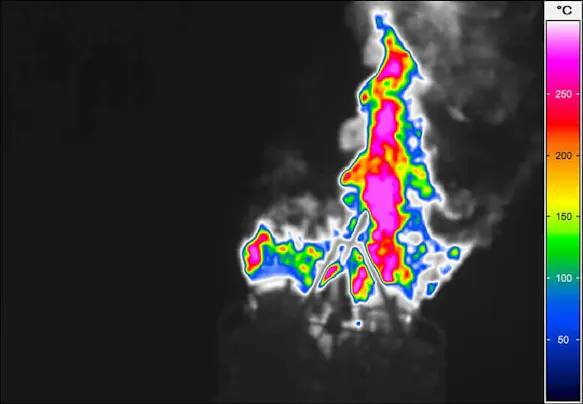

Application of Infrared Camera Systems for Contactless Temperature Measurement of Chemical Reactions

Chemical reactions are endogenous or exogenous proceedings resulting in heat flow. Imaging of temperature distribution by means of thermal imaging does not only allow punctual measuring of heat flows, but also enables analyses of entire process chains. Contactless measurement brings additional advantages since measuring of reacting chemicals is possible in the first place respectively connections to multiple contacting temperature sensors can be left out.

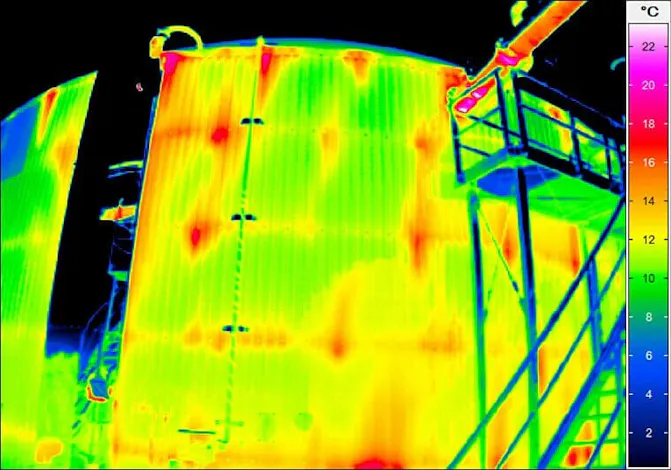

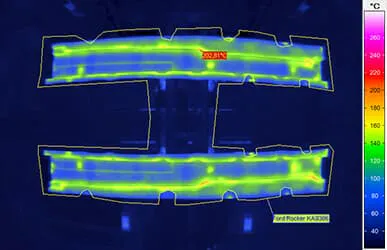

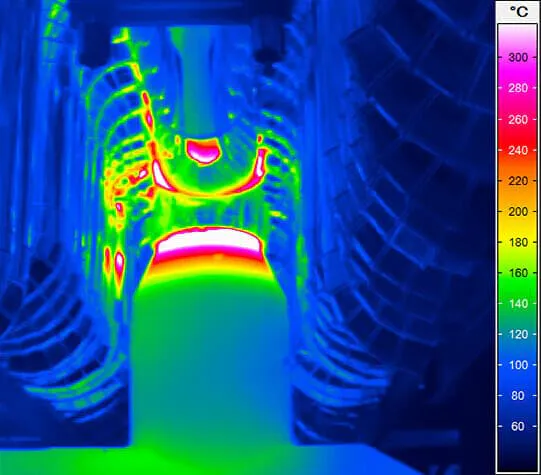

Testing of Reactor Insulation with Thermography

Reactors in chemical industry are strongly insulated in order to ensure the required reaction temperatures while protecting the environment against too high temperatures. Reactor insulations as well as any of their supply pipes and discharges have to meet highest requirements and must be checked in the respective way. Infrared camera systems provide a quick and detailed overview on leakages.

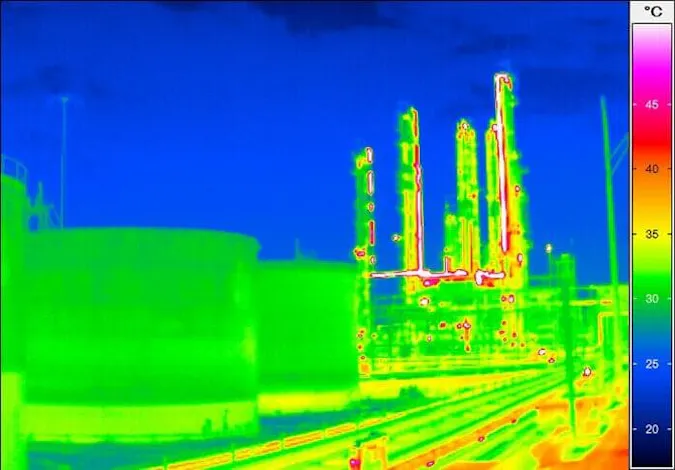

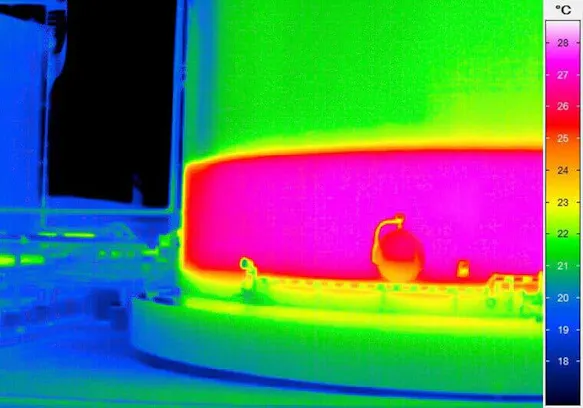

Liquid Level Monitoring of Tanks by Means of Infrared Camera Systems

Liquid and foamed chemicals are often kept in tanks. For this purpose, thermography provides an opportunity to monitor the liquid level of tanks. The temperature difference between the area containing liquids or foams and the empty one above is used for detection with thermal camera systems.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.