Tire Inspection with Thermography

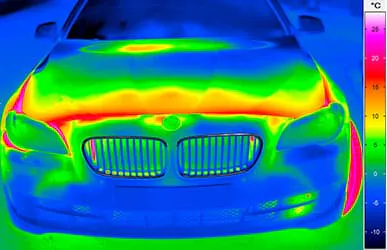

Mechanically stressed car components like tires are a continuous issue for quality inspection and related R&D improvements. At Bridgestone Corporation in Hofu (Yamaguchi prefecture in South-Western Japan) new test procedures for off-the-road tires for construction and mining vehicles (OR tires) had to be developed to meet the literally growing scale of performance concerning the carrying capacity.

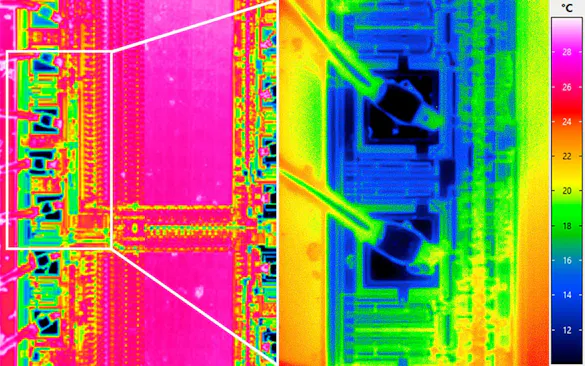

Huge dump trucks like a Komatsu 960E-1K can carry more than 300 tons of mine rock. When this monster moves on stony soil for many hours a day the workload on those tires is enormous. The long-term tests realised by Bridgestone run in different factories and include parallel inside and outside thermal inspections. The inside inspections are accomplished after several holes have been drilled into the tires carcass, while the outside measurements concentrate on external peripheral structures.

InfraTec Solution

Bridgestone Corporation

Ozaha Hamajata / Japan

www.bridgestone.com

Infrared camera

ImageIR® 8300

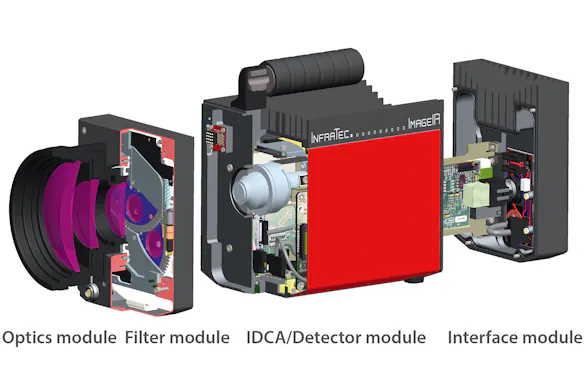

To allow a precise measurement during different rotation speed settings a very exact triggering interface for the infrared camera is required – no problem for an ImageIR® 8325. Utilising its nanosecond precision trigger interface the high precision camera collect data with a temperature resolution of 20 mK, very short integration times in the microsecond range and extreme high frame rates.

InfraTec’s Japanese partner IR Systems has developed a complete turnkey solution which allows long-term automated test sequences with constant thermography measurements. Since the chosen cameras are equipped with 10,000 hour MTBF longlife coolers the monitoring processes can be performed for extensive test periods. An exploding 2 m tall tire can cause pretty severe damage, so the low-maintenance and stable running cameras were installed in a protected, hardly accessible operational test cell.

Bridgestone Corporation was so much convinced by the first ImageIR® units being chosen that they decided to use this camera as measuring device for several test facilities they are realising.