Infrared Thermography During Bonding and Sealing

From the car body to the headphone – innovative material mixes made of modern fibre composites and well-tried metals are playing a more increasingly important role as materials in lightweight construction for industrial and household goods. The most varied composite fibre materials, such as carbon-fibre reinforced plastic (CFRP) and glass fibre reinforced plastic (GFRP), are combined with aluminium and magnesium as well as with high-strength and ultrahigh-strength steels. Joining such multi-material mixes imposes partially very high demands on the technology and manufacturers involved in this.

Bonding and sealing have established themselves as practicable joining technologies besides riveting, screwing and clinching. Thus, for example, the typical large contact surfaces facilitate the strength of large, thin lightweight composites for bonding. Consequently, components with less wall thickness and thus less weight can be installed. At the same time, the use of adhesives and adhesive tapes increases technological flexibility. Both can be processed manually and automatically. This opens up new possibilities for the production of single pieces as well as for serial production.

Detect and Exactly Localise Errors

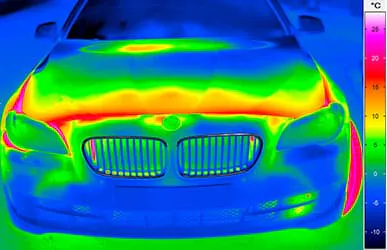

Infrared thermography has already been used for years during bonding and sealing for monitoring and controlling technological parameters, such as the geometry of the adhesive application, adhesive temperature and adherend temperature as well as curing temperature.

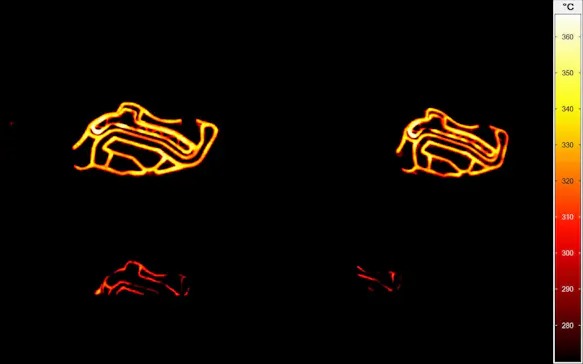

Whether an adhesive joint actually has the required properties with regard to geometry of the adhesive area and adhesive bond, for example, can also now be tested by means of infrared thermography. The quality of the respective joint can be accurately tested non-destructively by means of images taken by a thermal and geometrical high-resolution thermographic camera. Certain methods of active thermography, such as lock-in thermography, have proven to be particularly suitable in practice. Thus, users have the possibility to characterise even more complex lightweight components, which consist of various structures and partially multi-layered material mixes.

The Following Types of Errors Can Be Detected by Using Thermographic Systems

Errors regarding adhesive application, temperature of the adhesive and adherend temperature

Shape/size errors as an indication of just partially joined components

Errors in the temperature curve with conclusion based on e.g. the amount of adhesive used

Position errors with reference to incorrectly positioned tools and joined parts

Faults in the curing and cooling process as well as in the mould temperature control

Material defects, cavities, inclusions, holes, etc.

Delamination

Suitable Thermography Systems

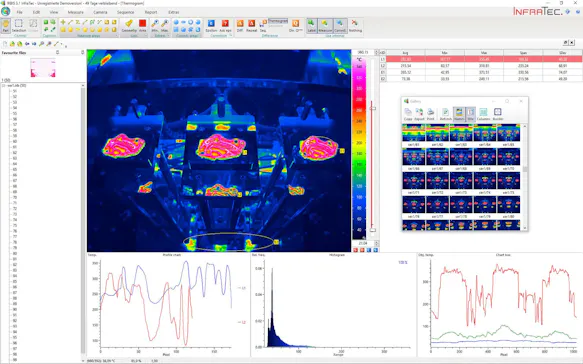

InfraTec offers a wide range of hardware and software for testing joints – ranging from single fixed thermographic cameras with cooled and uncooled detectors up to complex turnkey thermographic automation solutions using thermographic systems of various technologies. The measurement accuracy of the cameras used provides the basic requirement for reproducible tests. Due to high geometrical resolutions up to (2,560 × 2,048) native IR pixels and excellent thermal resolutions up to a range of just a few thousandths of a degree even slightest variations can be detected, which can provide indications of technical deviations. At the same time, the wide range of powerful lenses ensures optimum adjustment to the overall conditions of the measuring task as well as to the size of the measurement objects.

Record and Evaluate Data in Real Time

The recording of thermal image data is normally triggered by the machine control system of the production plant. Sturdy, GigE-Vision compatible interfaces ensure loss-free transmission of the data to powerful, passively cooled, continuously operational industrial PCs, which are integrated into modern industrial control cabinets. The recorded images and sequences are evaluated simultaneously in real time by means of the corresponding thermographic software for the actual production process. At the same time, numerous algorithms are available, which enable multilevel, non-linear evaluation under thermal and position-related aspects. Based on this data evaluation, users can monitor processes exactly and optimise process times. Recipes and user accounts can be conveniently managed with the software. A database connection ensures integration into the existing system environment of the user.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Your Benefits at a Glance

The use of high-quality thermographic cameras with detector formats up to (2,560 × 2,048) native IR pixels and a thermal sensitivity in the millikelvin range

Specially designed INDU-SCAN software, based on application experience developed from a variety of industries

All system components are suitable for rugged 24/7 continuous use in an industrial environment

The use of various fieldbus interfaces such as Profinet, PROFIBUS, CC-Link

Competent support from the feasibility study, including the development of the task and project outline right up to the preparation of a specification sheet

Planning and implementation based on standardised solutions such as in Eplan, CAD, etc.

Implementation and commissioning of turnkey solutions including briefing and training of staff

Support and service from a single source

Innovative measurement technology based on skills, which have been developed from more than 30 years of practical experience in the field of thermography