Thermography in Process Automation

The company Isabellenhütte Heusler GmbH & Co. KG has identified this potential at an early stage and uses infrared thermography for the quality assurance of their low resistance precision resistors.

Heat is one of the most important parameters for weal and woe during production processes and for product quality. Therefore, measuring heat has always had major relevance which is reflected by the early use of temperature sensors during the automation of production processes. Now the fast visualization of temperature distributions with non-contacting infrared thermography allows even more complex automated solutions without using contacted temperature sensors.

InfraTec Solution

Isabellenhütte Heusler GmbH & Co. KG

www.isabellenhuette.de

Infrared camera

VarioCAM® series

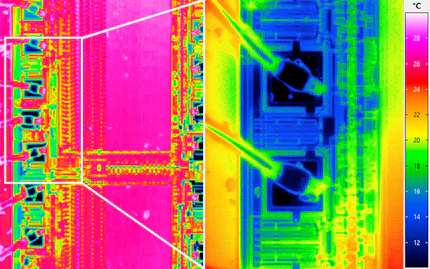

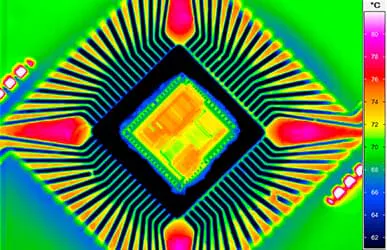

The company Isabellenhütte Heusler GmbH & Co. KG has identified this potential at an early stage and uses infrared thermography for the quality assurance of their low resistance precision resistors. In this application the stationary camera of the VarioCAM® series proves its very high measuring accuracy. Temperature differences of only 35 mK can be detected. Besides this excellent thermal resolution also the possibility to securely measure smallest details provides an essential measuring basis for further automation. This is achieved by a higher detector resolution of (384 x 288) Infrared Pixels, a special close-up focussing as well as by close-up and microscopic lenses.

Furthermore Mr. Dobener of the company Isabellenhütte Heusler GmbH & Co. KG particularly appreciates the very easy integration of the VarioCAM® series into the production facilities. That applies for both the mechanics of the camera that stands out with its compact and rugged design and for the data interface with a speed of up to 60 frames per second. The matching functionality of the software development kit supports the precise control of the camera. The trigger ports of the thermographic camera allow for the direct synchronization with the control software of the measuring device. All measuring data are fully issued digitally in real time. Thereby the production facilities can respond even to smallest temperature variations in order to always keep the products of the company Isabellenhütte Heusler GmbH & Co. KG at the very highest level.

Examples of ow resistance precision resistors

Mikrothermografieaufnahmen von niederohmigen Präzisionswiderständen