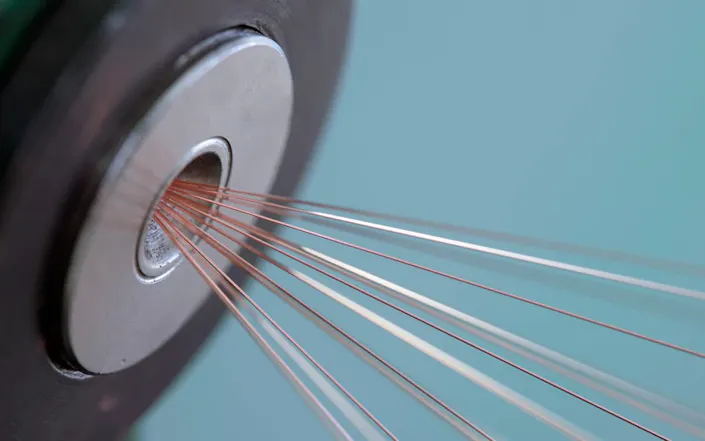

Nickel‐titanium Wires in Tension Test

How do solid materials change structurally? The engineers Prof. Stefan Seelecke and Marvin Schmidt from Saarland University investigate this fundamental question in materials research. Both consider this topic with the help of micro-thermography. Their cutting‐edge basic research ensures that we will have even more energy‐efficient electric devices to use at home in future.

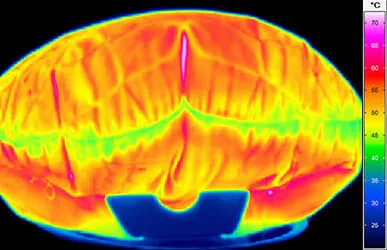

In the last few decades, researchers have worked increasingly on alternative cooling technologies that do not use refrigerants containing fluorocarbons. Technologies such as ferroelastic cooling promise high effectiveness, a more efficient use of resources and reduction of greenhouse gas emissions. This form of cooling uses wires of a pseudoelastic shape memory alloy based on nickel/titanium (NiTi). A mechanical load on the NiTi wires causes large, reversible deformations due to a stress‐induced martensitic transformation. A martensitic structure is created, and thermal energy is given off to the surroundings. With removal of the load, the stress‐induced martensitic structure changes back into the original austenite. Thermal energy from the surroundings must be expended for this.

InfraTec Solution

Saarland University

Zentrum für Mechatronik u. Automatisierungstechnik

www.zema.de

Infrared camera

ImageIR® 9300

To achieve the maximum savings potential of ferroelastic cooling, the entire deformation process must be regulated optimally. The researchers want to control parameters independently, such as frequency or phase shift between the mechanical stress and heat transfer. In addition, they want to measure the resulting cooling performance for a specific material and a specific device geometry. To do this, Seelecke and Schmidt have developed an imaging measurement platform.

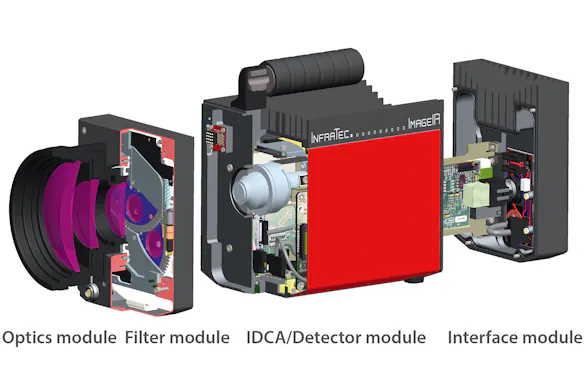

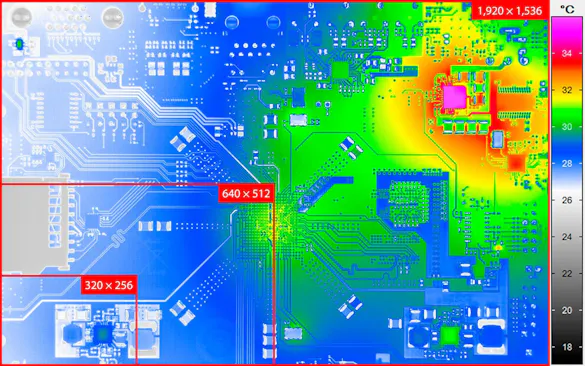

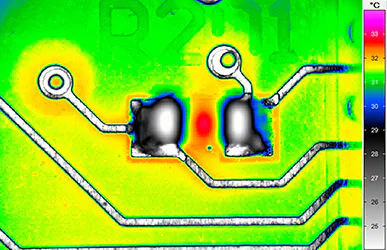

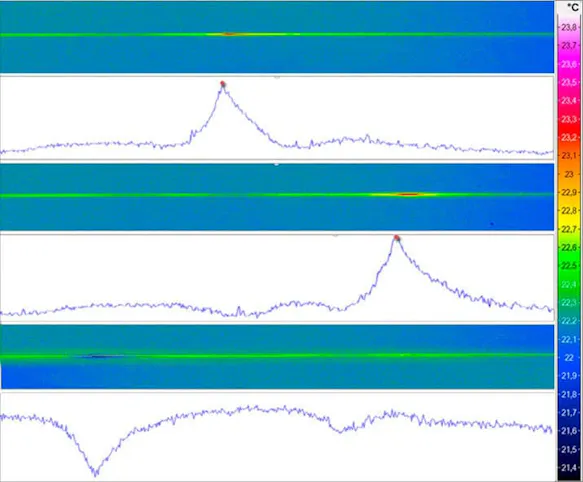

It works with an ImageIR® 9300. The high‐end thermal imaging camera is equipped with a 1x microscope lens and detects the wire to be measured, whose diameter is only approximately 150 μm. Exact thermographic temperature measurement even on longer wire sections is ensured through the geometric resolution of 15 μm. In this way, the researchers can retrace the ferroelastic cooling effects very precisely. Thanks to the camera's (1,280 x 1,024) IR‐pixel detector, the Saarbrücken‐based scientists can monitor long parts of the tiny wire and record the structural changes. The high temporal resolution of the ImageIR® 9300 of up to 106 Hz in full‐frame format also lets them follow even brief temperature changes.

Evaluation of the thermograms is just as sophisticated. Reflection effects and emission coefficients that are complicated to determine are among the regular challenges. Seelecke and his team therefore value the integrated correction model of the supplied IRBIS® 3. “With the software we can compensate for astonishingly many effects. That clearly makes our work easier.” The software, together with the large detector format and the high geometric, thermal and temporal resolution, forms a package that makes the ImageIR® 9300 ideally qualified for use in materials research. And by the way, this combination will hopefully do its part to ensure that we all can save more energy and protect the environment in the foreseeable future.