Early Fire Detection in the Power Plant

Today's power and heating supply in the city of Bern is hardly imaginable without the Forsthaus energy centre (Energiezentrale Forsthaus – EZF). This power plant combines a refuse incineration plant (KVA) with a wood heating power plant and a combined gas‐steam power plant. About 120,000 tons of waste are recovered in it annually. This results in about 360 GWh of electrical energy and 290 GWh of thermal energy. The Swiss company relies on the WASTE‐SCAN infrared monitoring system from InfraTec for the early fire detection.

Monitoring with Seven Thermographic Cameras

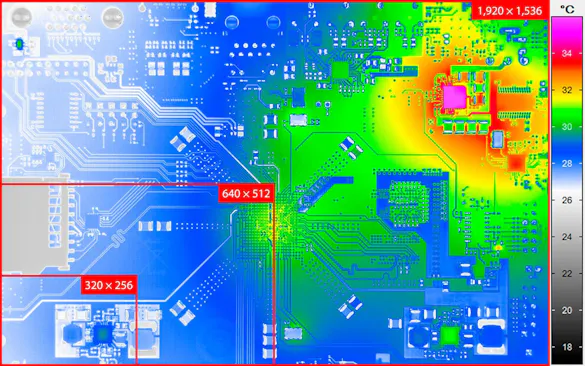

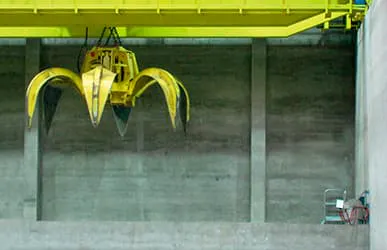

On peak days, significantly more than 100 vehicles deliver up to 700 tons of waste in the large storage bunker of the refuse incineration plant, in which several thousand tons of waste are stored. To ensure that this volume can be monitored efficiently and reliably around the clock at ignition sources, e.g. from glowing embers brought in externally or heating induced by the activity of microorganisms, multiple infrared cameras have been used since 2015. Originally started with five cameras, the thermal imaging early fire detection installed onsite meanwhile records a total of seven cameras, which are located in special protective housings. "Two of them are fixed mounted. The employees monitor the hoppers and shredder hole," explains Thomas Andres, operations manager of the EZF. "The remaining cameras are equipped with pan/tilt heads and are used for safeguarding the waste bunker, two storage areas and both crane parking spaces."

InfraTec Solution

Amager Ressource Center (ARC)

Waste Incineration Plant

www.a-r-c.dk

Thermography automation system:

WASTE-SCAN infrared monitoring system

Some of these cameras combine an infrared camera with a visual camera as a so-called twin-system. Together with their powerful, electronically controlled pan/tilt heads they provide the possibility of optimised area monitoring. Twin systems and single cameras are divided into two separate asynchronous systems, both having their own computer software architecture. If one system fails, the other one can be further used autonomously.

The handling of the systems has been solved in a similarly flexible manner. The operation is basically fully automated. The infrared cameras and their positions can also be controlled at any time directly by hand, however. All it takes is to switch to manual control. The operating personnel are thus able to effectively neutralise the ignition sources detected below the angle of view of the camera automatically. All other functions of WASTE-SCAN remain unaffected and continue to operate to the full extent. The very latest digital interfaces secure the connection to the cameras via a network allowing for convenient remote control as well as the implementation of routine diagnostics. This can take place from multiple maintenance and operating stations. The results can then also be checked on monitors immediately.

Protection of Bunkers and Surrounding Areas

This complex concept guarantees maximum security and reliability. Apart from the actual storage bunker, the monitoring also includes the surrounding open areas. The waste stored there is very often covered with dust and highly flammable materials. If ignition sources reach this area during transportation with the crane or in some other way, this also signifies a serious fire hazard. With WASTE-SCAN, effective early fire detection can thus be ensured even beyond the bunker.

The EZF is optimally equipped even in the case of an emergency. The infrared cameras are connected directly to all control and extinguishing systems via Profibus interfaces. If a fire is detected by means of the cameras or other sensors, this automatically triggers an alarm, which is signaled to the extinguishing system and activates a corresponding sprinkler system. Thomas Andres does not need an additional employee who constantly keeps an eye on the early fire detection system, "The camera system runs fully automatically. Our two crane operators only check whether it is in operation."

Long-term Stability of the Complete System

One of the main focal points of the development engineers at InfraTec is the trouble-free and preferably comfortable, continuous operation of WASTE-SCAN. This is because there are many other components that have to work flawlessly for a long period of time besides the infrared cameras. This includes, for example, the industrial computers and control cabinets of the system, even when these are not exposed to any exceptional environmental conditions. Pan/tilt heads, connection cables that move almost continuously, and of course the cameras themselves, constantly have to withstand loads due to dirt, heat and smoke.

Reliability at the highest level is extremely important for the operation of such power plants. After all, the EZF covers about one third of the power requirement and twelve percent of the heat requirement of Bern's inhabitants. None of them wants to be sitting in the dark without any heating.