PIR uc LWIR 600

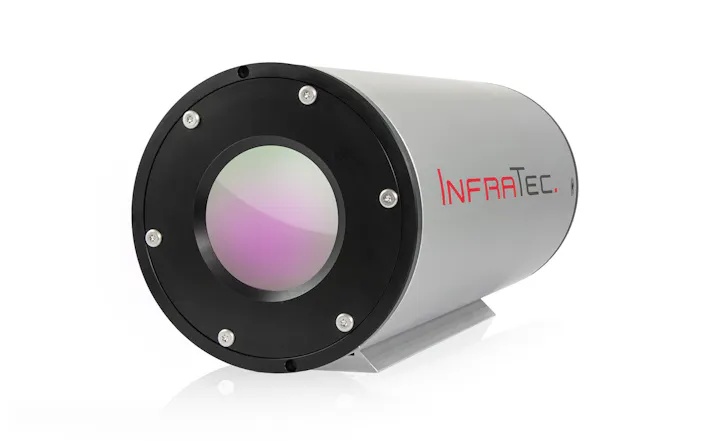

Stationary thermographic camera for industrial use.

Microbolometer detector with up to (640 × 480) IR pixels

Longwave spectral range (7.5 … 14) µm

IR frame rate up to 30 Hz

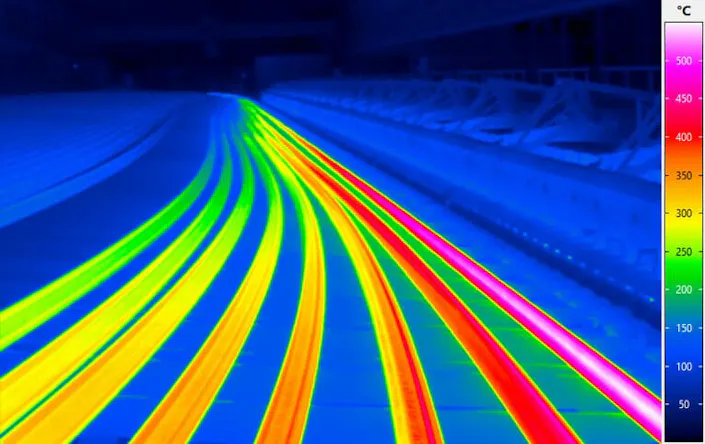

Temperature measuring range of (-35 … 545) °C

Robust industrial cameras with protection degree IP65

Compact light metal housing

Attractive price-performance ratio

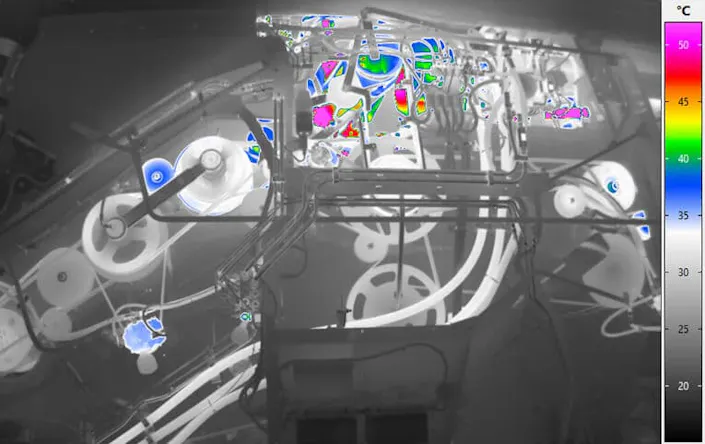

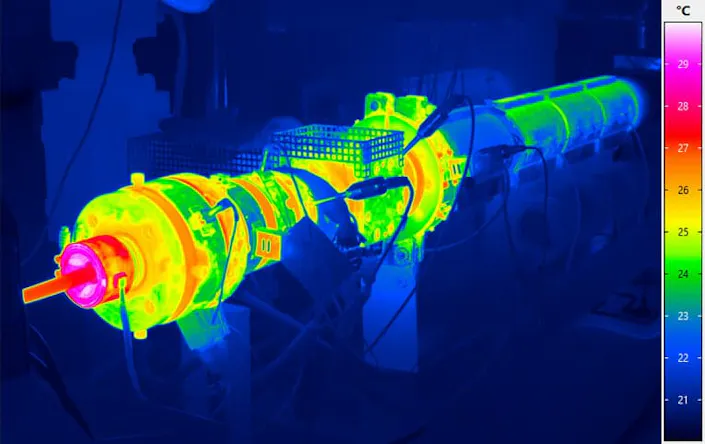

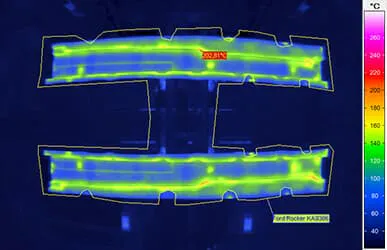

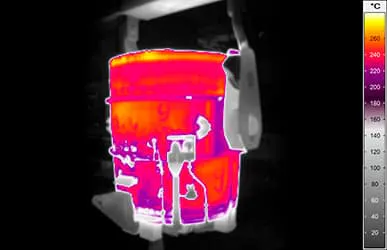

High resolution thermal images for temperature measurement

Constant excellent optical and metrological performance even in harsh industrial environments

Adaptation of the image geometry to almost every measuring situation

Optional power supply via data network

Versatile Industrial Camera

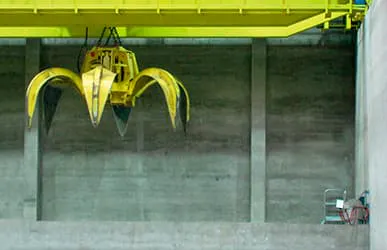

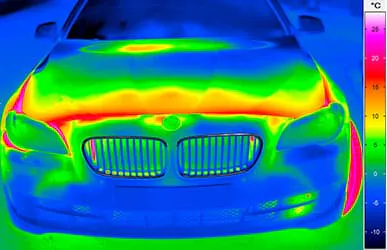

The robust light metal housing reliably protects the inside of the models in the camera series PIR uc LWIR 600 for the longwave spectral range from climatically and mechanically extreme conditions. High temperatures, dust, dirt – these thermographic cameras with protection degree IP65 are able to withstand very much. This qualifies them for numerous applications, such as in the area of process monitoring and security technology, which require a stationary camera for the contactless temperature measurement on many different surfaces. In addition to this robustness, the compact design and small dimensions simplify the integration into diverse industrial processes.

Usage for Turnkey Thermography Automation Systems

Easy handling, enormous resistance of the cameras in continuous operation and low maintenance already characterise the PIR uc LWIR as a standalone solution. Above all, however, such characteristics qualify these models as components of turnkey thermography automation systems. These can be combined so flexibly with numerous evaluation and analysis programs of the IRBIS® 3 software range. Thus, users can adjust the control of the cameras and the recording of data optimally to their specific requirements.

Product Flyer

Get all the information you need at a glance in our product flyers

Technical Specifications

| Spectral range | (7.5 … 14) µm |

| Pitch | 17 µm |

| Detector | Uncooled microbolometer focal-plane array |

| Detector format (IR pixels) | (640 × 480) |

| Temperature measuring range | (-20 ... 135) ℃ / (0 ... 400) ℃ |

| Measurement accuracy | ± 5 °C or ± 5 % |

| Temperature resolution at 30 °C | 0.05 K |

| Frame rate | 25 Hz |

* Depending on model

** In selected measurement ranges

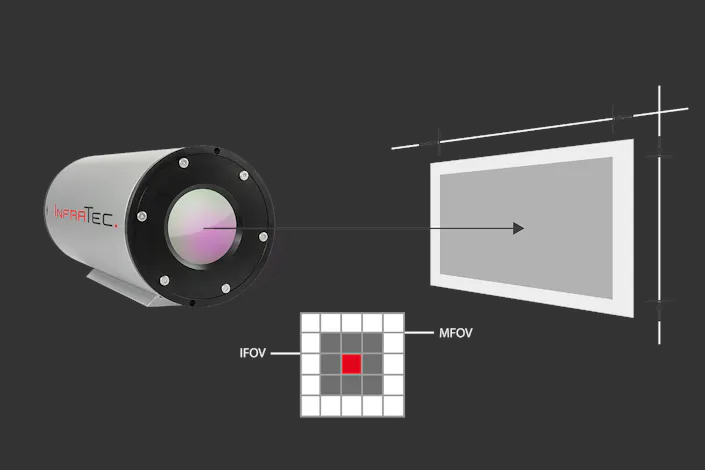

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.