Steel Production and Steel Processing

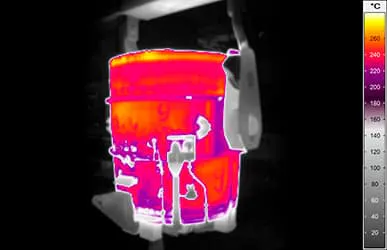

Modern lightweight components and the higher stress of components require the manufacturing and processing of new steel alloys. Such treatment processes involve significant thermal sequences which can be captured by infrared systems. Anyone controlling these sequences directly in the production process secures a decisive competitive edge. For by using thermography, you improve your quality assurance and minimize production losses during production of high-grade steels at the same time.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Steel Production: Benefits of Using Thermography

Permanent monitoring and process control

Savings in maintenance thanks to low-maintenance operation of infrared measurement and monitoring systems

Longer service life of equipment (e.g. ladles, torpedo cars)

Maintenance-free continuous operation thanks to special stainless steel camera housing

Use even in adverse industrial environments

Provision of alarm and process data via web interface in the company network

Increase in production safety and avoidance of accidents with at least serious consequences for employees, equipment and production operations (e.g. in the event of ladle breakages)