Increasing the Geometrical Resolution with MicroScan

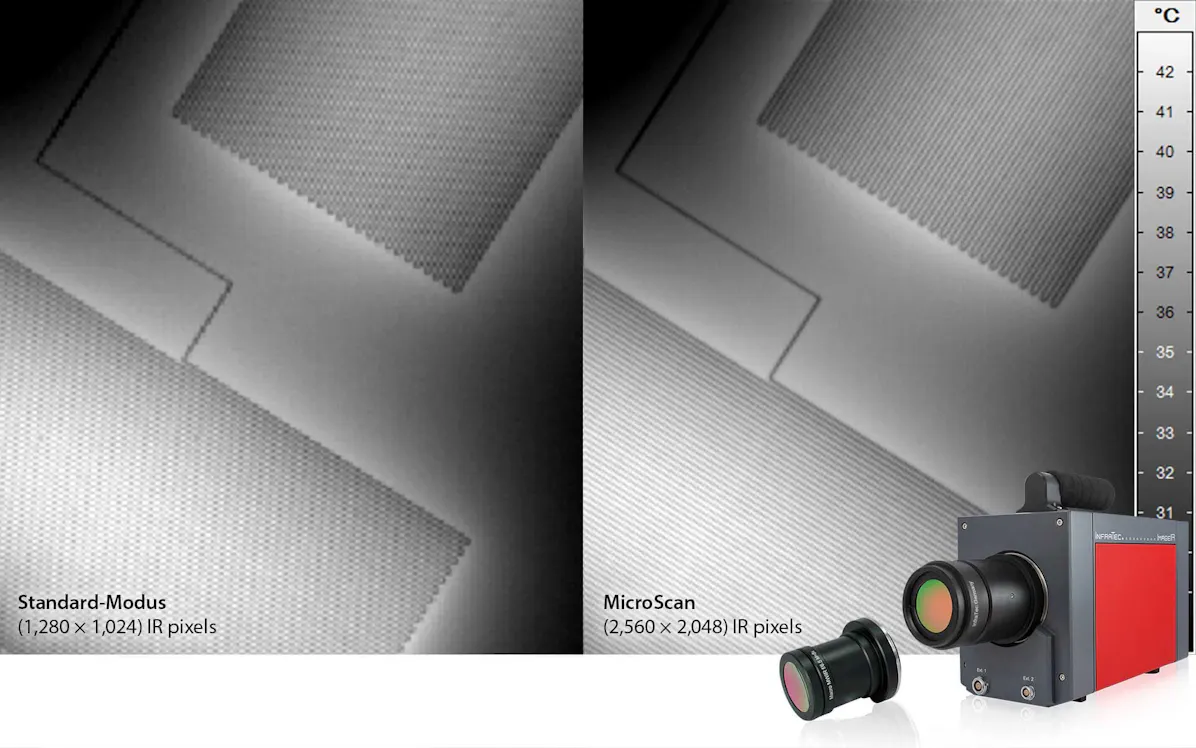

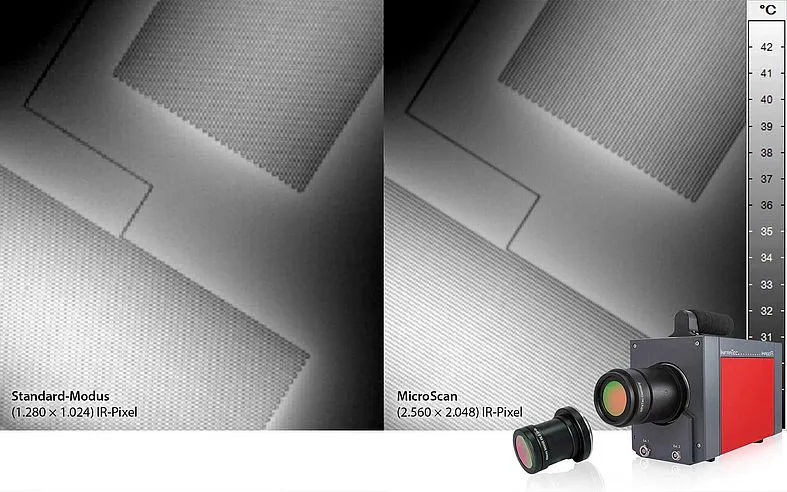

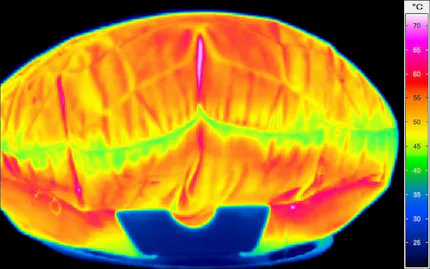

One of the key innovations of the high-end camera series ImageIR® and VarioCAM® High Definition is MicroScan. With the help of this function the number of pixels being used can be quadrupled compared to the native number of pixels of the FPA detector being used. This allows thermography of significantly higher image quality. Users can apply infrared cameras to produce thermograms with geometrical resolutions up to (2.560 x 2.048) IR pixels. Such recordings show measurement objects with a superb image quality.

Usage of MicroScan Function

The Following will be Achieved by MicroScan

Depending on the point of view, MicroScan has the following effects:

It...

quadruples the number of pixels

doubles the spatial sampling rate and thus the (spatial) Nyquist frequency of the measurement system

divides the pixel grid in half

reduces aliasing artefacts

increases the quality of the images

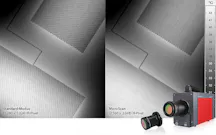

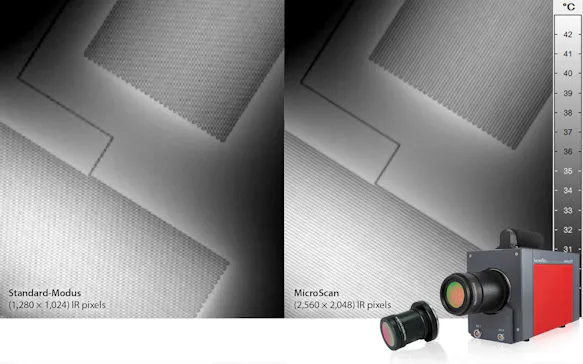

The practical significance of the difference between the use of the native detector format of an infrared camera and the image format obtained using MicroScan can best be depicted visually. The following comparison shows the images of a Siemens star – one without and one with the MicroScan function activated. In each of the two figures two red, circular markings are shown. Inside the large circle, the frequency of the Siemens star's rays exceeds the Nyquist frequency of the detector. The smaller circle encloses the part of the Siemens-star in which the ray’s frequency exceeds the Nyquist frequency with MicroScan. For reasons of mechanical stabilization, however, the Siemens star here no longer has a ray structure, but is compact.

Aliasing and Nyquist Frequency

This example of the Siemens-star reveals the significant improvement in image quality with MicroScan. The sampling frequency of the infrared camera results from the reciprocal of the so-called pixel pitch, which is the distance between the centre of two neighbouring pixels. These are effects, which cannot be eliminated by the application of software-based filters. Aliasing occurs if the sampling rate of a measuring instrument is lower than half of the frequency of the measured signal. This frequency is called Nyquist frequency:

ƒnyquist = ½ · ƒsampling

In our application, however, this is not a temporal frequency, which is expressed in Hz, but spatial frequencies with the unit m-1 (1 / meter). The sampling frequency of the thermographic camera results from the reciprocal of the so-called pixel pitch, which is the distance between the centre of two neighbouring pixels. Assuming that this pixel pitch of a thermogram corresponds to a distance of 2 mm on the measurement object, the Nyquist frequency would be 1/2 * 1/(2 mm) = 0,25 mm-1. Structures in the object that have a periodicity < 4 mm therefore generate aliasing artefacts. Thus, the sampling frequency at which the original signal is measured, has to be more than twice as high as the highest frequency contained in the original signal ƒsignal:

ƒsampling > 2 · ƒsignal

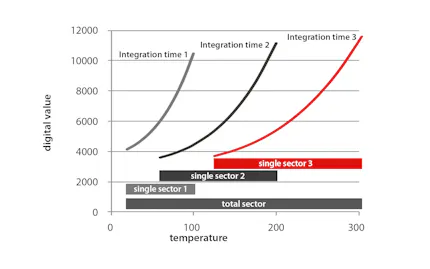

This is How MicroScan Works with the Camera Series ImageIR®

In the models of the camera series ImageIR®, a fast-rotating MicroScan wheel integrated in the infrared camera ensures the practical implementation of MicroScan. Four plane-parallel windows permeable to infrared are integrated in the filter wheel, each tilted by a precisely defined angle. The tilting causes the image on the detector to be displaced laterally by half a pixel pitch for each window. These individual images are merged in real time to form a thermogram with four times the number of pixels. Each pixel in the image represents a real temperature measurement value and not an interpolated pixel.

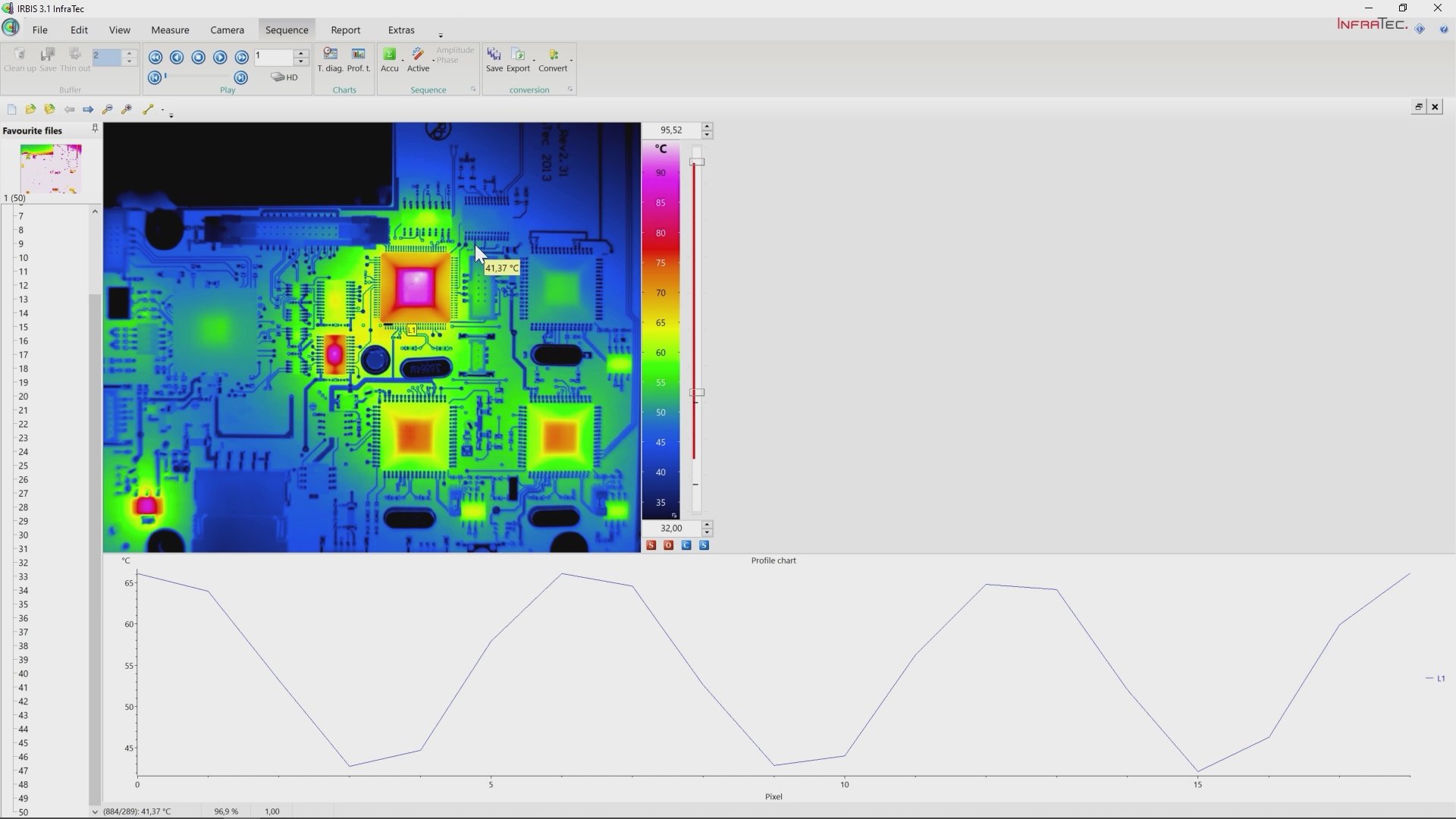

This is not only very precise, but also very fast. How fast can be demonstrated on the example of the ImageIR® 8300 hp. If the infrared camera runs with (640 x 512) IR pixels in full frame mode at its maximum frame rate, the MicroScan wheel spins at more than 5.000 rotations per minute. Due to such high speeds, users applying MicroScan can thermographically analyze processes with fast moving targets or rapidly changing temperatures. Therefore, this technology is predestined not only for use in microthermography, but also for a wide variety of security applications.

In the VarioCAM® High Definition camera series the MicroScan function is implemented via a tilted germanium disc positioned between the IR detector and the optics.

The disk rotates and deflects the beam path for all pixels of the sensor matrix. Four individual images, taken every quarter turn of the disk, are then combined to form a high-resolution thermal image. The offset between images is precisely defined, so that the distances between the pixels are fully filled. The fill factor, which describes the relationship between the sensitive cell and the insulation, increases to 100%. This results in a complete image of the measurement object.

Infrared Cameras from InfraTec with MicroScan Function

Users of the MicroScan Function Benefit from The Following Advantages

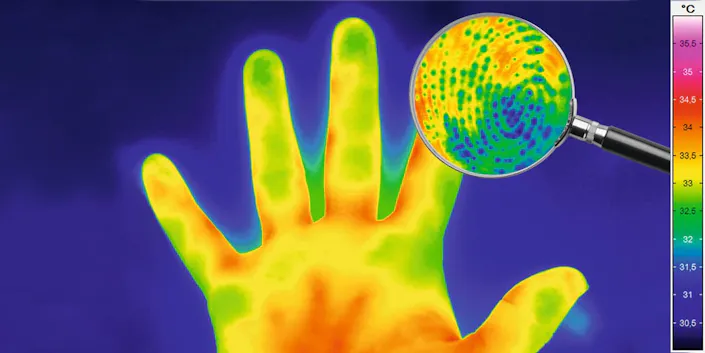

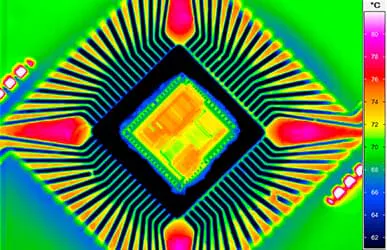

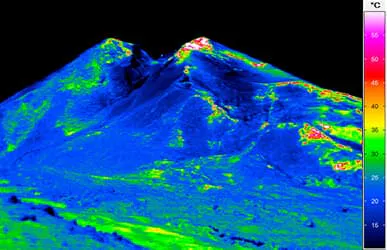

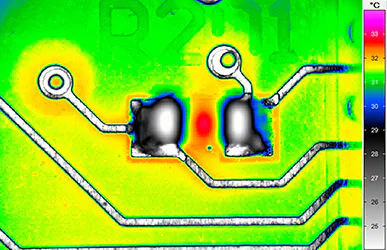

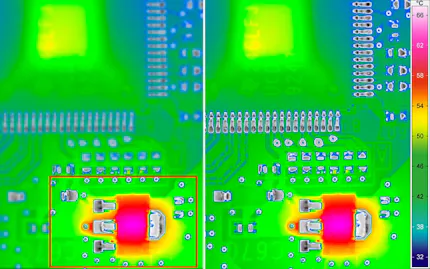

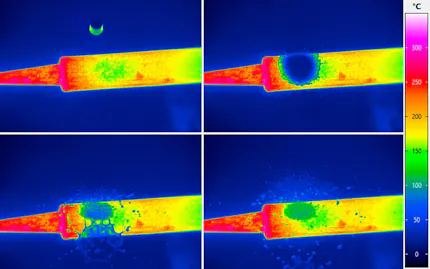

In the everyday use of thermographic cameras, MicroScan proves itself particularly through an obvious quality gain with regard to the recognisability of details. The images show the objects to be measured in extremely high resolution. This is illustrated by a glance at the edges and structures of the objects: Even oblique object edges or curves are exactly reproduced by digital zoom. The use of MicroScan simplifies the evaluation and analysis in the field of thermography for users because significantly more details can be easily recognized in the images. The MicroScan function is suitable for continuous operation and can be used without time restrictions.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.