High-end Cameras

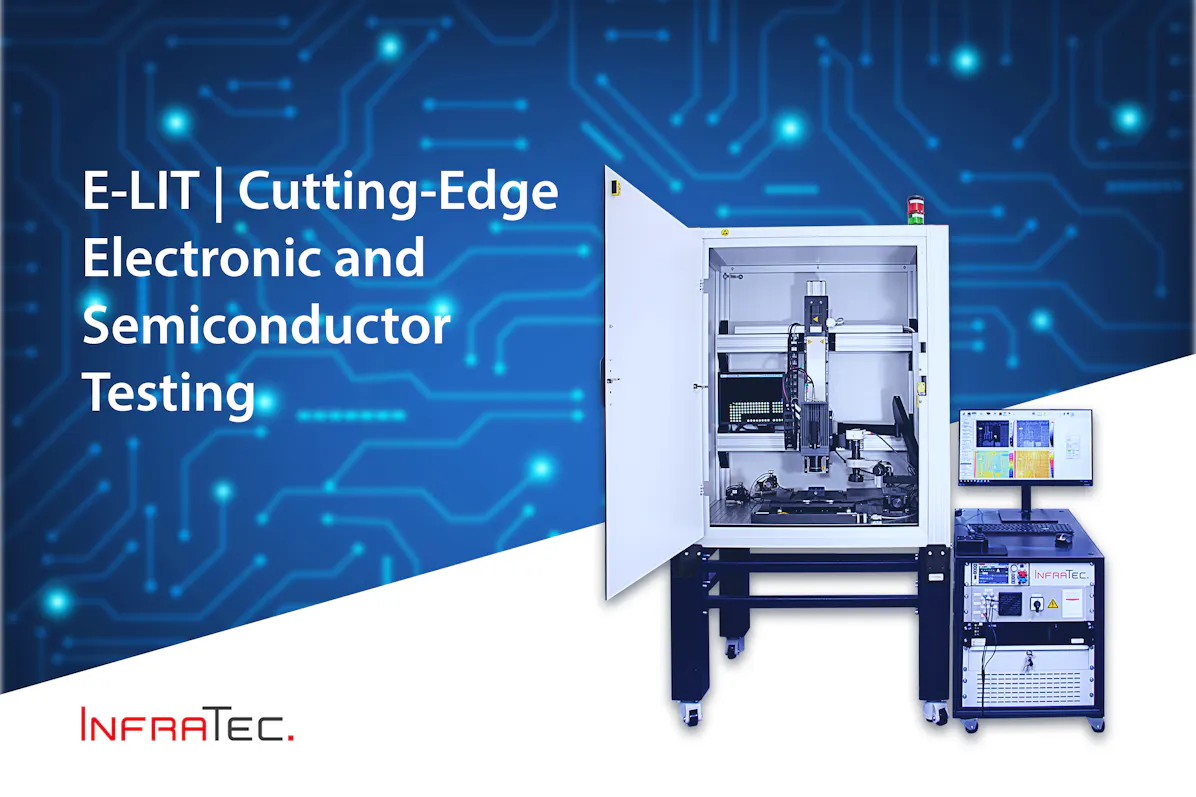

High-end thermographic systems for R&D, process monitoring, and non-destructive testing

Designed to meet the highest demands in challenging applications

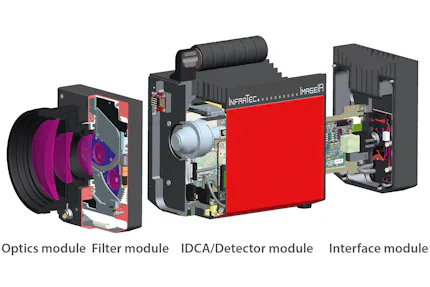

Modular design ensures maximum flexibility and adaptability

Precision optics with interchangeable infrared lenses, filters, and more

Easily configurable to suit specific application requirements

High-end Cameras Meet Highest Demands

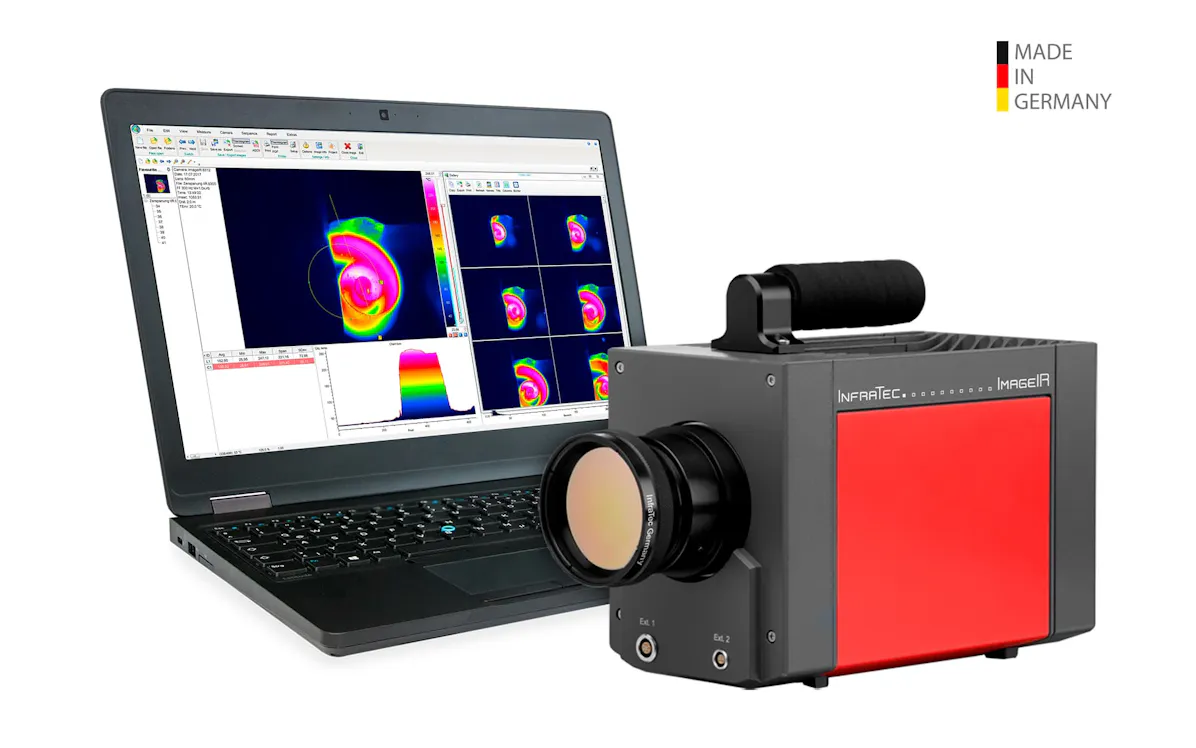

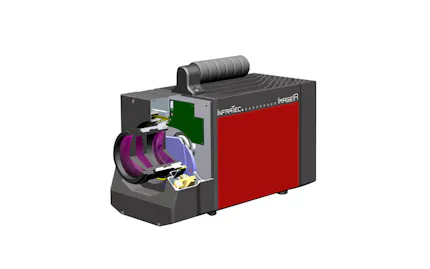

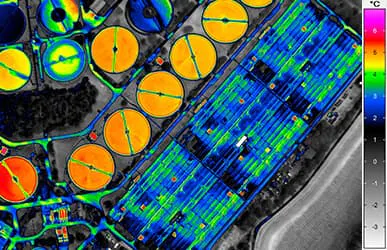

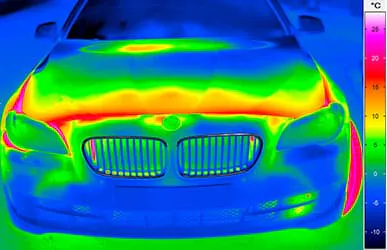

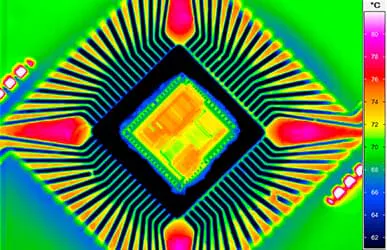

Our high-end cameras are designed for particularly demanding applications and, due to their characteristics, are tailored to users who require high-performance and flexibly configurable thermal imaging camera technology. Cooled photon detectors of different types, spectral sensitivity ranges and formats are used.

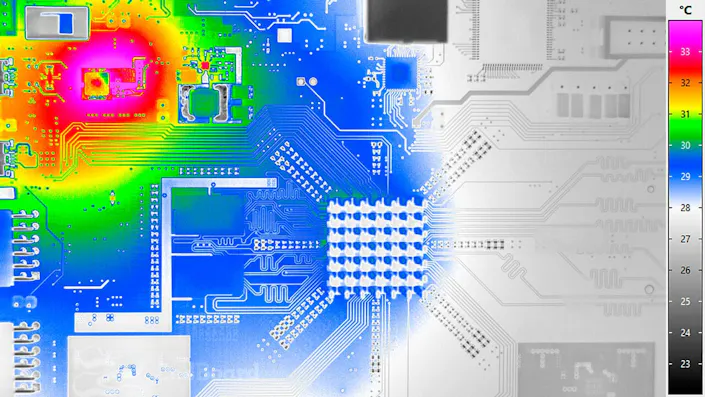

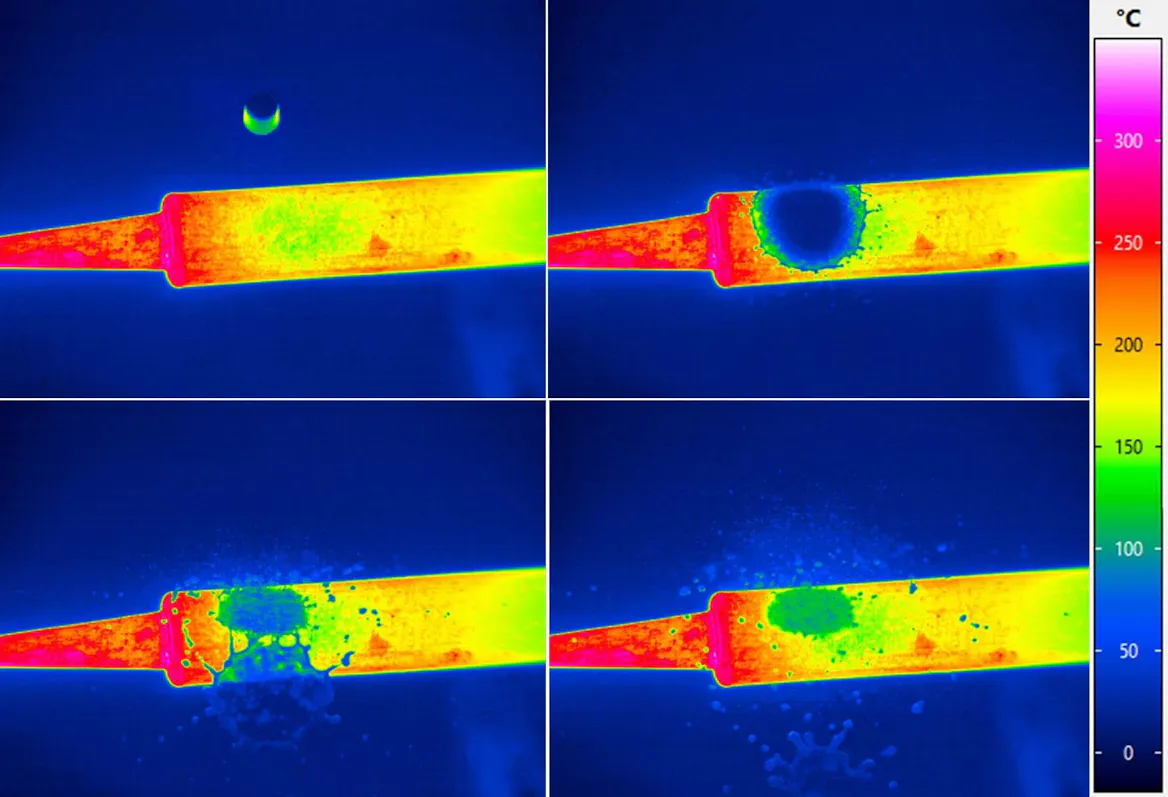

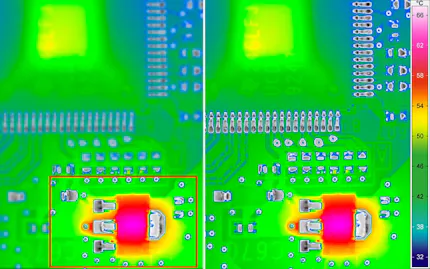

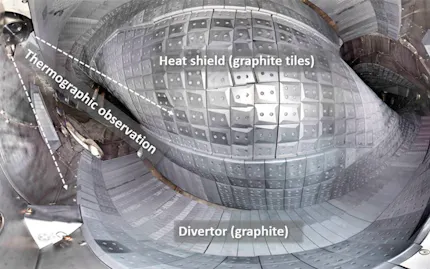

The high-end cameras of the ImageIR® series offer users outstanding performance data, including the highest thermal sensitivity, first-class geometrical and temporal resolution for precise measurements as well as high-speed modes to optimally image even extremely fast processes and moving objects. Due to a modular basic concept, individual system configuration and optimal adaptation of the performance data to the task are easily possible. For example, our ImageIR® cameras are used in research and development, in non-destructive analysis and in process monitoring.

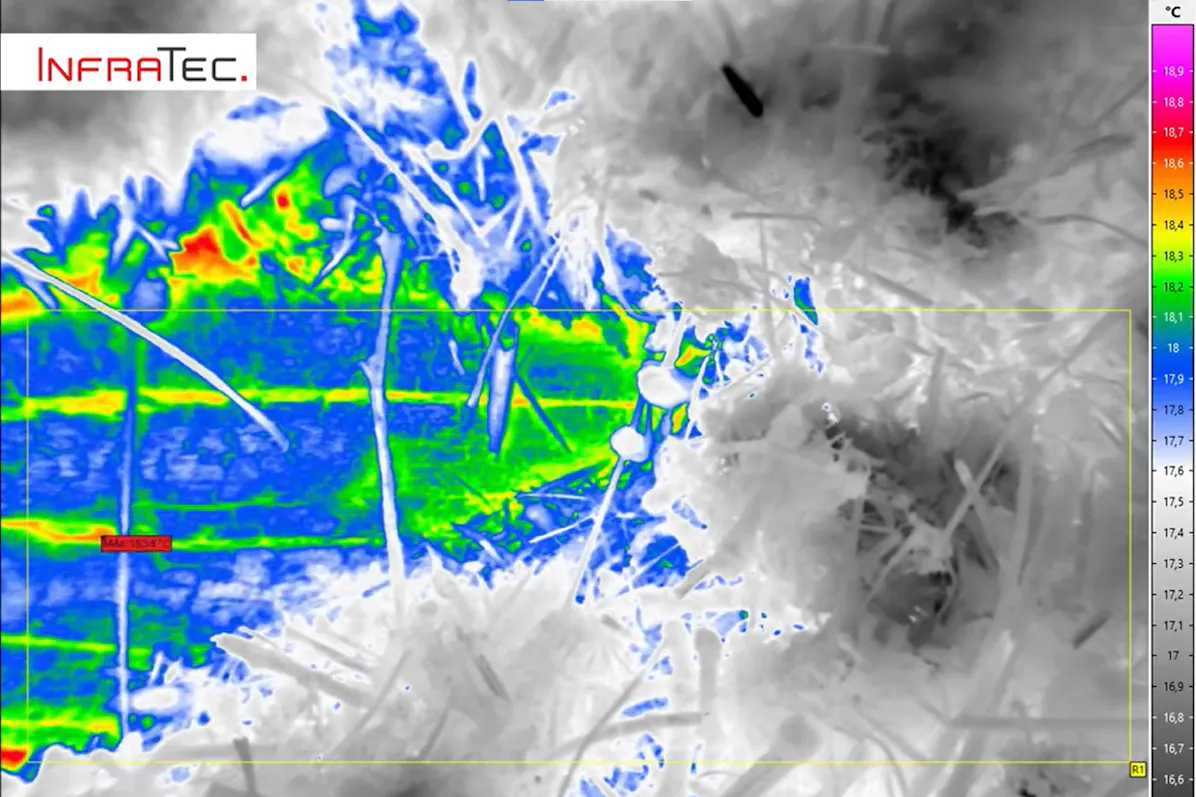

In combination with the thermography control and analysis software IRBIS® developed by InfraTec, the cameras of the ImageIR® series set high standards as an efficient tool for complex thermographic analyses.

Video Gallery High-end Camera Series

Detector Formats of the High-end Thermography Systems ImageIR®

| Detecor fomat / MicroScan resolution (IR pixels) | (2.560 × 2.048) | (1,920 × 1,536) | (1,280 × 720) / (2,560 × 1,440) | (1,280 × 1,024) / (2,560 × 2,048) | (1,280 × 1,024) | (640 × 512) / (1,280 × 1,024) | (640 × 512) | (320 × 256) |

| ImageIR® 12300 | ◼ | |||||||

| ImageIR® 10300 | ◼ | |||||||

| ImageIR® 9800 | ◼ | |||||||

| ImageIR® 9500 | ◼ | |||||||

| ImageIR® 9400 | ◼ | ◼ | ||||||

| ImageIR® 9300 | ◼ | ◼ | ||||||

| ImageIR® 8800 | ◼ | ◼ | ||||||

| ImageIR® 8300 hp | ◼ | ◼ | ||||||

| ImageIR® 8300 | ◼ | |||||||

| ImageIR® 7300 | ◼ | |||||||

| ImageIR® 5300 | ◼ | |||||||

| ImageIR® 4300 | ◼ |

Spectral Ranges of the High-end Thermography Systems ImageIR®

| Camera Series | Spectral Ranges |

| ImageIR® 12300 | MWIR / (3.4 ... 4.9) µm |

| ImageIR® 10300 | MWIR / (3.6 ... 4.9) µm |

| ImageIR® 9500 | LWIR / (7.7 ... 12.5) µm |

| ImageIR® 9500 | MWIR / (3.5 ... 4.8) µm |

| ImageIR® 9400 | MWIR / (1.5 ... 5.5) µm |

| ImageIR® 9300 | MWIR / (1.5 ... 5.5) µm |

| ImageIR® 8800 | LWIR / (7.7 ... 10.2) µm |

| ImageIR® 8300 hp | MWIR / (1.5 ... 5.5) µm |

| ImageIR® 8300 | MWIR / (2.0 ... 5.7) µm |

| ImageIR® 7300 | MWIR / (1.5 ... 5.7) µm |

| ImageIR® 5300 | MWIR / (3.7 ... 4.8) µm |

| ImageIR® 4300 | MWIR / (3.7 ... 4.8) |

Features and Benefits of High-end Cameras

Spatial resolution with detector formats with up to (2,560 × 2,048) infrared pixels

Control via web interface

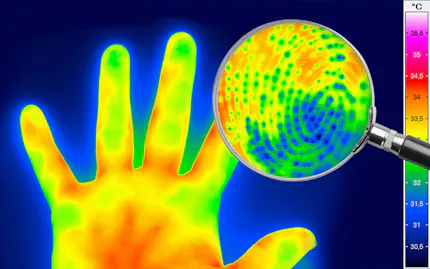

Precise detection of smallest temperature differences

Increases frame rates and thermal resolution at the same time using binning technology

Analysis of high-speed dynamic temperature changes and processes

More flexibility for upgrades and changes of components

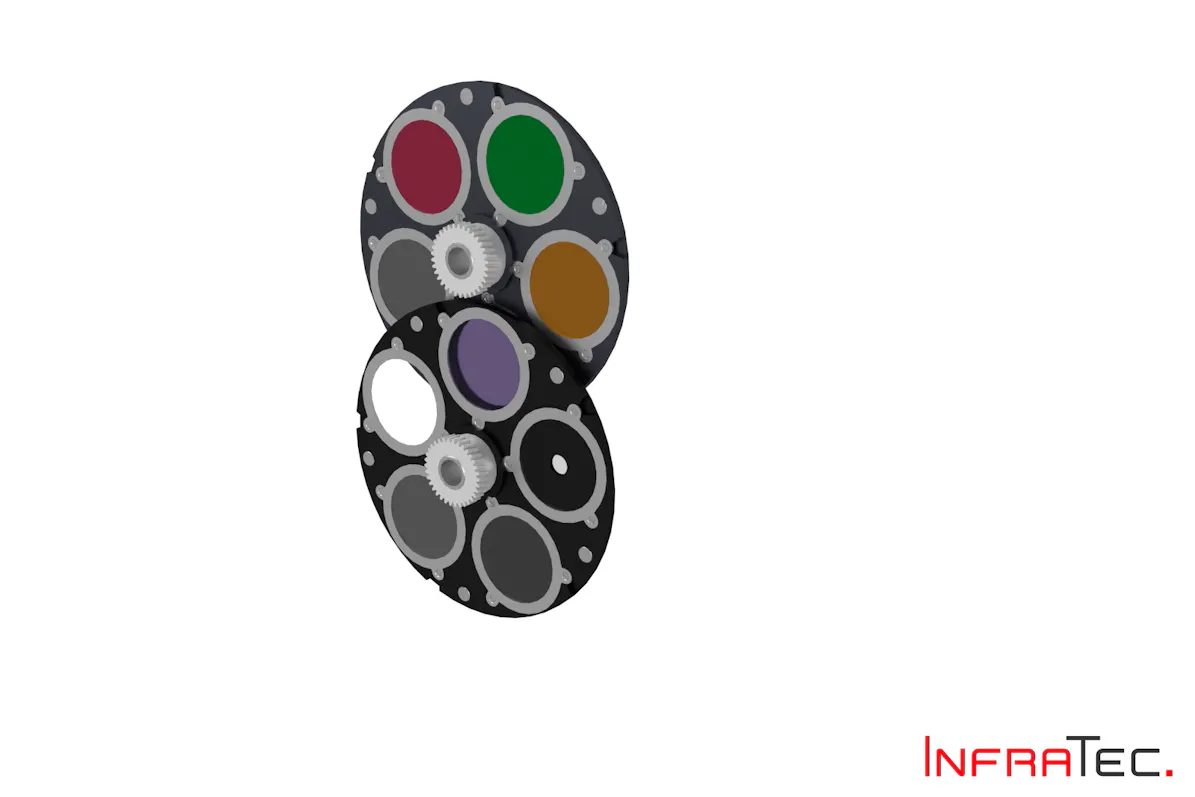

Flexible filtering by inbuilt two filter- / aperture wheels with up to 35 combinations

Precise triggering with only 10 ns jitter

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

You Need More Information about High-end Cameras?

There is high-end camera matching perfectly your specific requirements. To find out which one it is, just check out all the models in detail.