Active Thermography

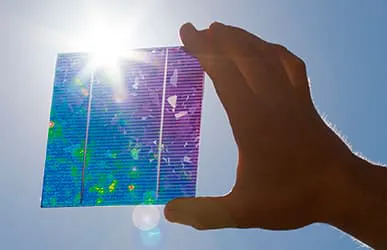

Various methods of active thermography like Lock-In Thermography and Pulse Phase Thermography are imaging procedures that perfectly suit for contact-free and non-destructive material testing. In connection with high-resolution infrared cameras, they allow for quick detection of material defects and open up new possibilities in research, development and quality assurance.

Active Thermography for Non-Destructive Material Testing

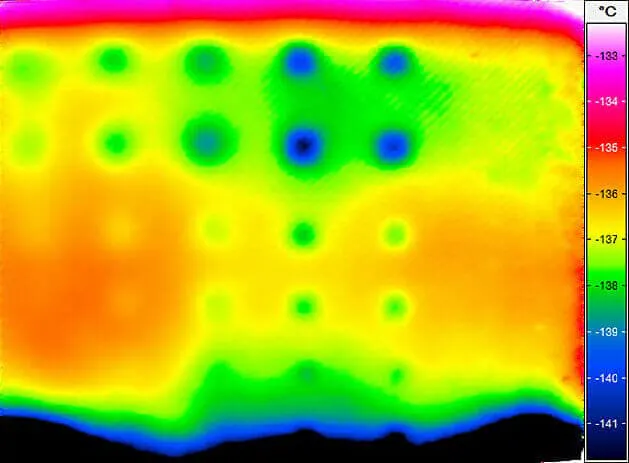

Active thermography is the induction of a heat flow by energetically exciting a test object. The heat flow is influenced by interior material layers and defects. These inhomogeneities can be captured on the surface by high-precision infrared cameras. The additional application of different evaluation algorithms improves the signal-to-noise-ratio which allows for detection of smallest defects.

Modular System Design for Precisely Fitting Inspections

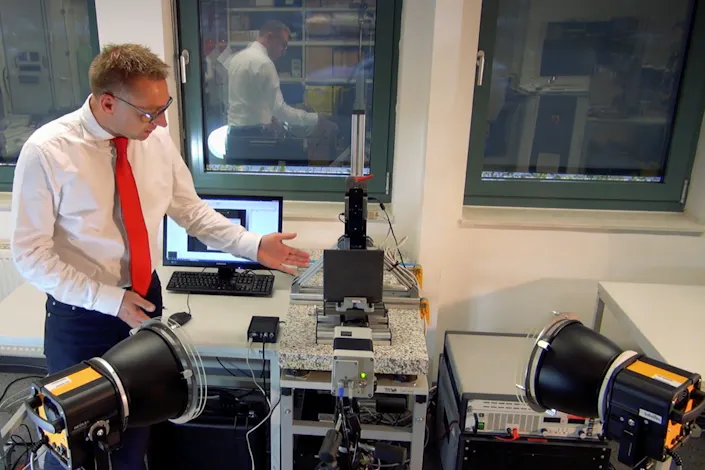

The versatile application options of active thermography require an elaborate configuration of every single inspection system. InfraTec offers a wide variety of necessary components along with a modular system architecture. The high-resolution infrared cameras, efficient control and evaluation software as well as the continuously operable excitation sources and controllers are interchangeable within the system and therefore allow a flexible adaptation to upcoming requirements.

Defect-specific Excitation Sources and Controllers

Different types of defects of various materials can be detected by utilising specific energetic excitation units. InfraTec chooses the suiting excitation source, such as high-performance flashes, inductive units, hot- and cold air blowers and homogeneous halogen radiators, for the respective test situation.

Online Events On Demand: Active Thermography

Efficient Material Testing – Non-destructive and Contactless

Theoretical background – mechanical force, stress and temperature Methods for analysis

Examples from practice with application samples – elastic periodical load test and fatigue test

Short overview about InfraTec products

Complementary technical lecture

"Contribution of Thermoelastic Stress Analysis in mechanics of materials and structures: some illustrations" from Prof. Vincent Le Saux, École Nationale Supérieure de Techniques Avancées Bretagne

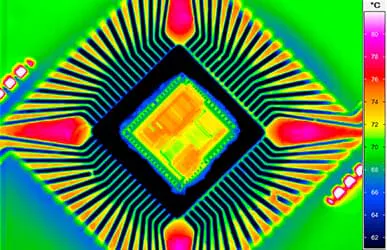

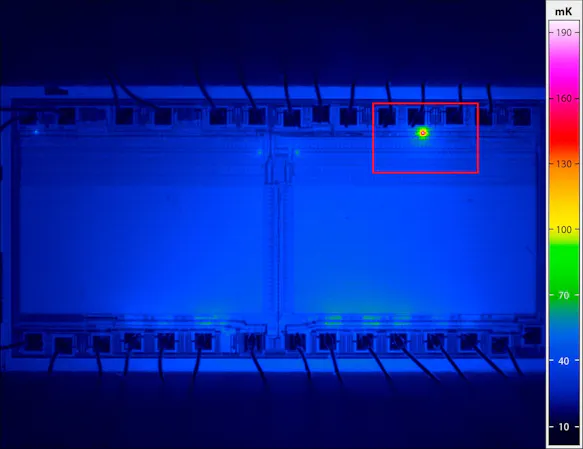

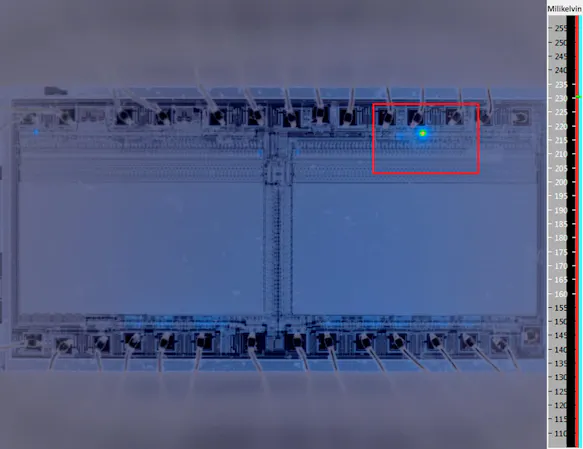

Infrared Lock-in Thermography for Inspection of Electronics and Integrated Circuits

Failure analysis and defect inspection, quality and process control and flexible R&D solution

Hotspot detection on printed circuit boards, integrated circuits, semiconductor material and multi-chip modules

Detection of faulty thermal connections of heat sinks, short circuits, soldering defects and wire bonding errors

Complementary technical lecture Semiconductor IR-LIT Analytics – Challenges and Case Studies from Marko Hoffmann; Infineon Technologies Dresden GmbH & Co. KG

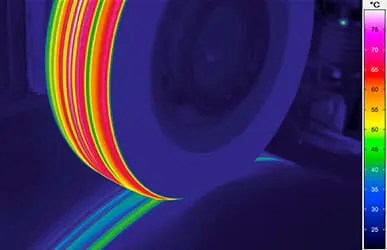

Lock-in Thermography in Electronics and Electrical Engineering

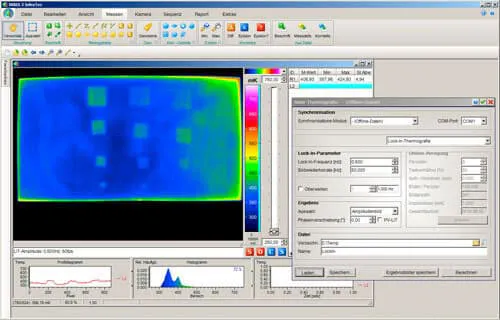

By means of lock-in analysis procedure of InfraTec's IRBIS® 3 active, errors that only cause mK or μK deviations can be reliably detected and assigned to their location:

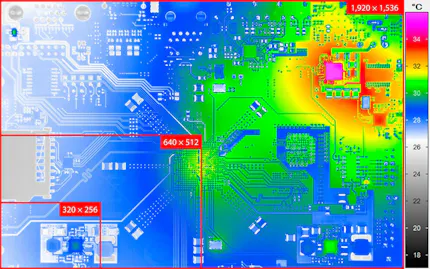

Infrared Cameras with Highest Precision

Cooled high-end infrared cameras with fast photon detectors of the ImageIR® series and non-cooled microbolometer cameras of the latest VarioCAM® High Definition generation are used for active thermography.

Geometric resolutions of up to (1,280 x 1,024) IR pixels and thermal resolutions far below 0.015 K are a precise technical basis for the detection of smallest material defects. High image acquisition frequencies allow for measurements of materials with high heat conductivity, such as metals. We also offer an extensive assortment of lenses and optics to image large test objects as well as microscopic structures.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

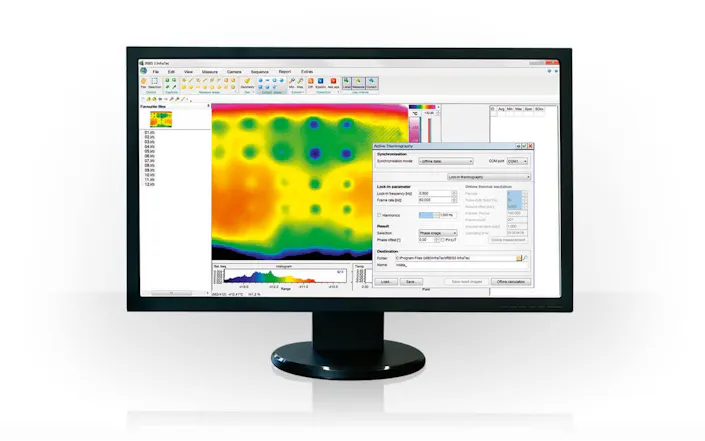

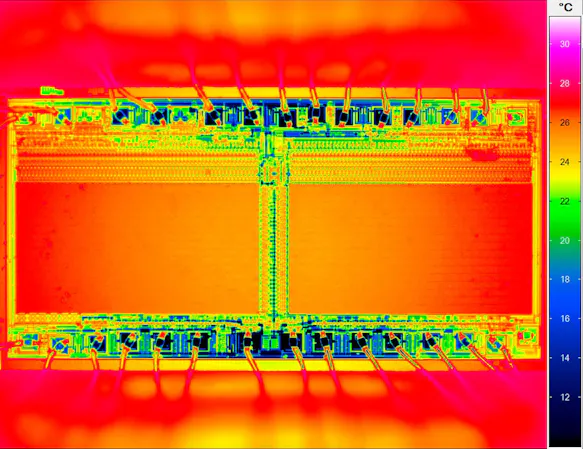

Efficient Control and Analysis Software for Active Thermography

The thermography software IRBIS�® 3 active analyses the thermo-graphic sequences, which have been generated during the test, and edits them to create a false colour image, in which defects can be marked for further evaluation or documentation. For this purpose, several different analysis procedures are available. The choice of the correct algorithm depends on the material characteristics, geometry and type of defects to be detected.

While the quotient method investigates the heat flow of the test object by reference to the increase and decrease of the surface temperature, the pulse-phase thermography (PPT) relies on the analysis of the temperature profile of different frequencies. For each frequency, two event images are generated, one amplitude- and one phase image. The lock-in thermography (LIT) analyses the sequence of periodic excitation of the test object.

Lock-In Measurement

Applications of Active Thermography

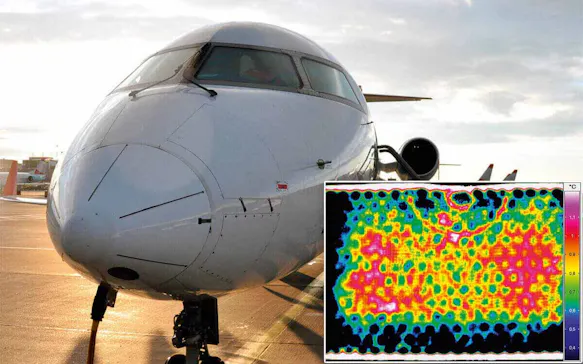

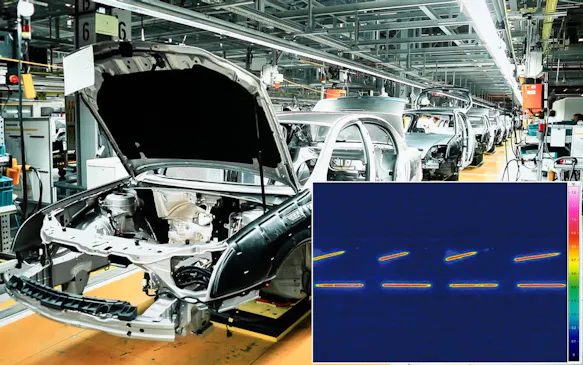

Active thermography is applied in most diverse manufacturing technologies for offline testing as well as inline testing of series production.

Detection of layer structures, delaminations and inserts in plastics

Detection in CFRPs of the automotive and aerospace industry

Investigation of interior structures or impacts on honeycomb lightweight constructions

Recognition of deeper material deficiencies, such as blowholes in plastic parts or ruptured laser welding seams

Product Flyer

Get all the information you need at a glance in our product flyers