Trigger Interface

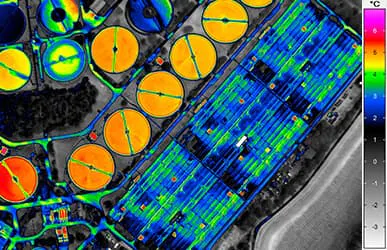

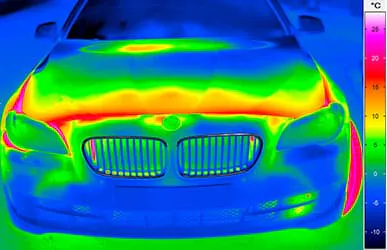

When using an infrared camera as a measurement system – whether in a laboratory setting or for process monitoring – it is essential to precisely control the timing of image data acquisition. For example, if the camera needs to be controlled externally or synchronized with other hardware, a trigger interface is required to input or output control signals.

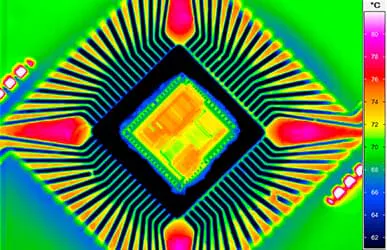

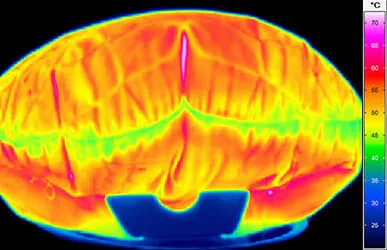

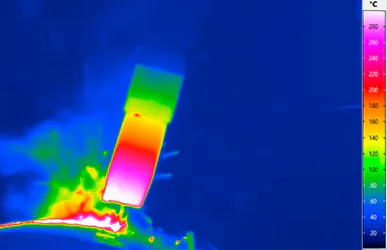

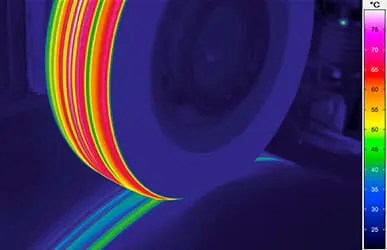

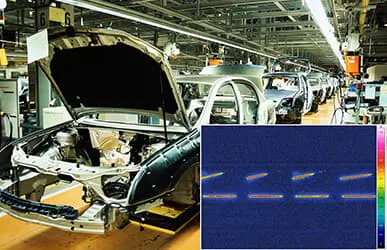

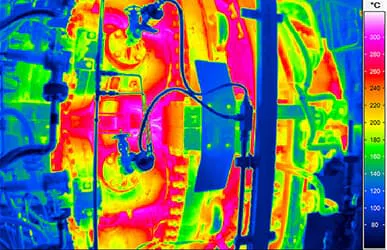

The camera's internal trigger interface guarantees high-precision, repeatable, and delay-free triggering, enabling the reliable capture of even very fast processes. For example, in lock-in thermography of a printed circuit board, the excitation and measurement cycles can be precisely synchronised. In process monitoring, an alarm can be triggered automatically when a threshold value is exceeded. Even significantly more complex trigger processes can run in parallel with the measurement data stream with high repeat accuracy and minimal delay.

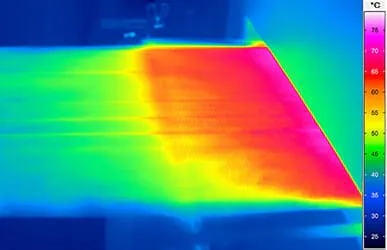

The trigger interface of ImageIR® cameras supports the processing of both incoming and outgoing analogue signals. For instance, an external voltage signal can be read directly from the camera and this information can be embedded into the thermographic image data.

Processing of Trigger Signals

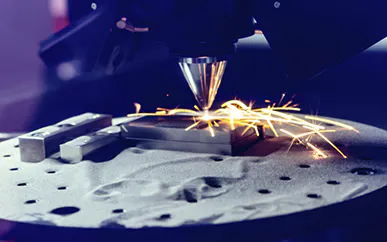

Triggering can be performed either via external hardware, InfraTec’s IRBIS® thermography software or through external software tools. For flexible integration of the thermography cameras into user-specific applications, the supplied Software Development Kit (SDK) enables custom expansion. This allows, for instance, the implementation of evaluation algorithms and their use for camera control via software commands. Control signals can be output through the trigger interface or alternatively via Ethernet or USB. The latest high-end models in the ImageIR® series are already equipped with a lightweight internal SDK that provides direct access to key camera functions.

Types of Triggering

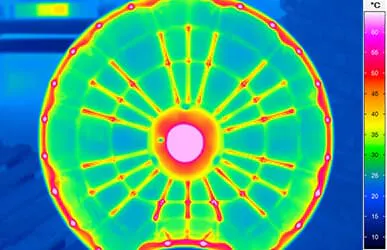

The trigger signal to be processed is generated either by the infrared camera itself or by external devices. To use the camera’s detector signal for synchronizing other devices, those devices must be connected to an output (OUT) of the trigger interface – the camera operates as the MASTER.

In addition to the detector signal, other signal types such as sine, triangle, or square waves can also be output as triggers.

If an external device is connected to an input (IN) of the camera, its signal, such as an analogue voltage, can act as a trigger. A typical application is external frame synchronization, where image acquisition is controlled by an external clock signal (camera as SLAVE). For maximum measurement precision, external detector synchronization is ideal for cooled cameras and higher frame rates.

Another application involves marking triggers, which can be used to “tag” specific image sequences for evaluation. Alternatively, the system can be configured to record only a defined number of frames following a trigger event.

How to Use Triggering

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.