Receive the Following Services with System Solutions from InfraTec

Events On Demand: System Solutions

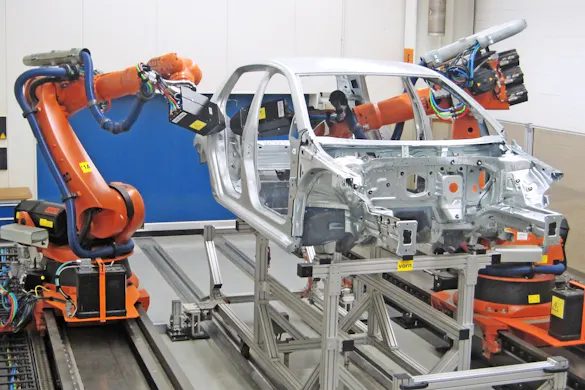

Thermography for Industrial Automation

Efficient quality control through fast, contactless temperature measurement during ongoing production

Flexible system solutions from modular components to fully customized turnkey setups

Integrated software for automated evaluation, documentation, and triggering of follow-up processes

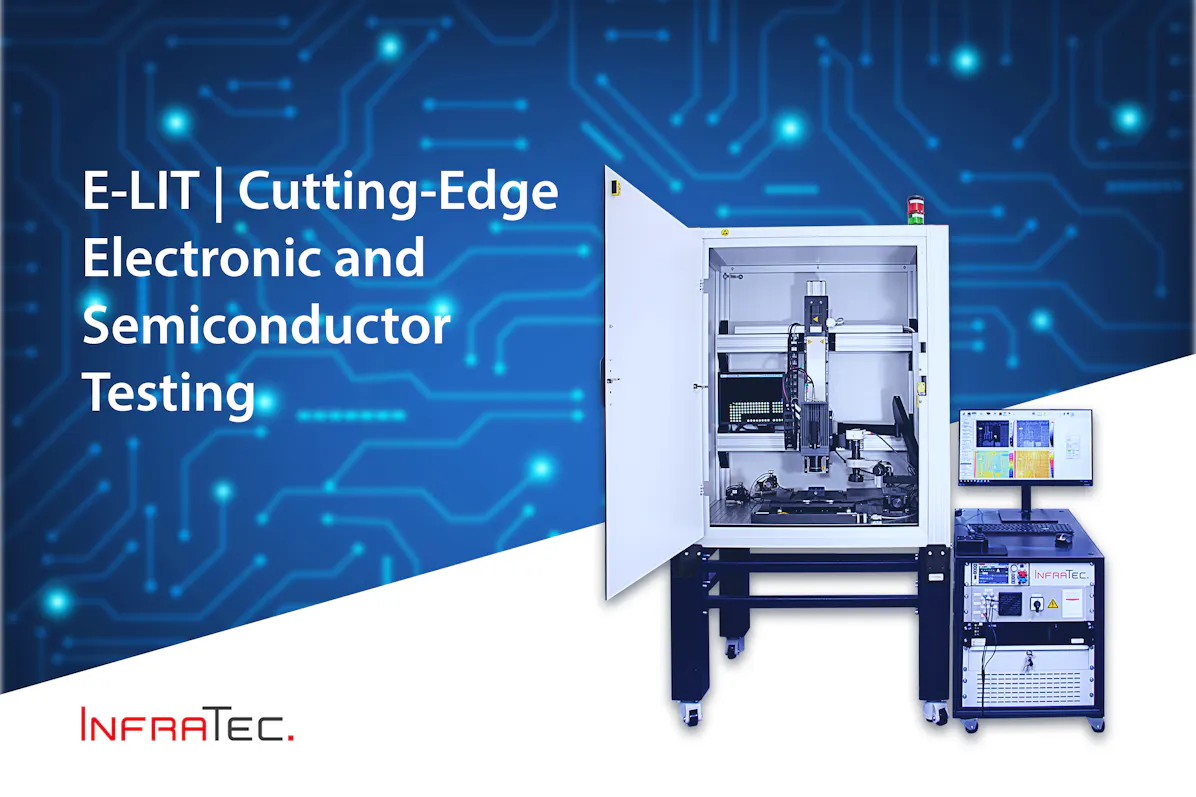

Infrared Lock-in Thermography for Inspection of Electronics and Integrated Circuits

Failure analysis and defect inspection, quality and process control and flexible R&D solution

Hotspot detection on printed circuit boards, integrated circuits, semiconductor material and multi-chip modules

Detection of faulty thermal connections of heat sinks, short circuits, soldering defects and wire bonding errors

Complementary technical lecture Semiconductor IR-LIT Analytics – Challenges and Case Studies from Marko Hoffmann; Infineon Technologies Dresden GmbH & Co. KG

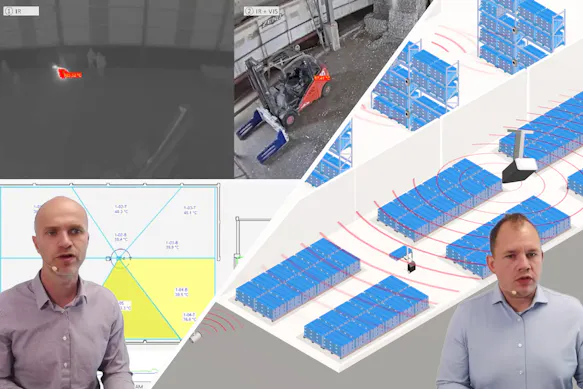

Thermographic Warehouse Monitoring for Fire Prevention

Thermography in early fire detection: challenges, important parameters and their influence

FIRE-SCAN for thermographic warehouse monitoring

FIRE-SCAN for monitoring Lithium-ion batteries

High resolution infrared cameras with pan/tilt heads

Special infrared cameras for stationary installation

High-Speed Thermography for Rotating Parts

Existing temperature measurement methods

High-speed thermography TRC mode: Setup

TRC hardware and software

Advantages of TRC mode and sample measurements

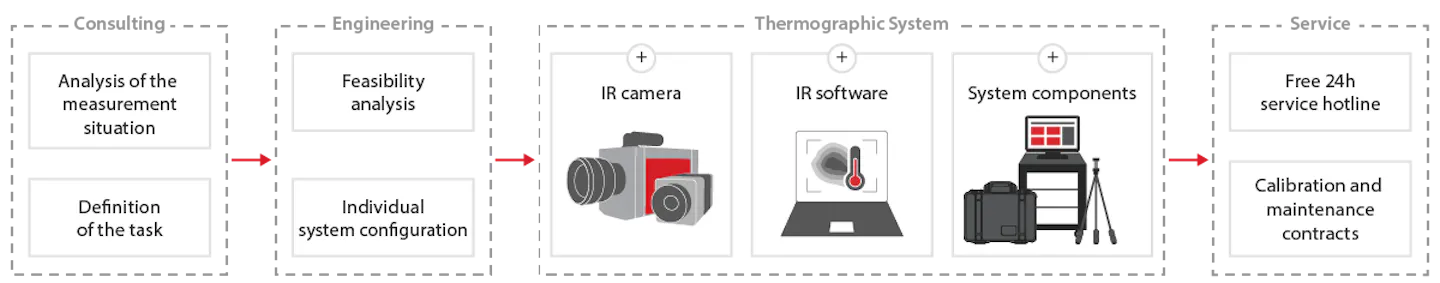

Thermographic Automation Solutions at a Glance

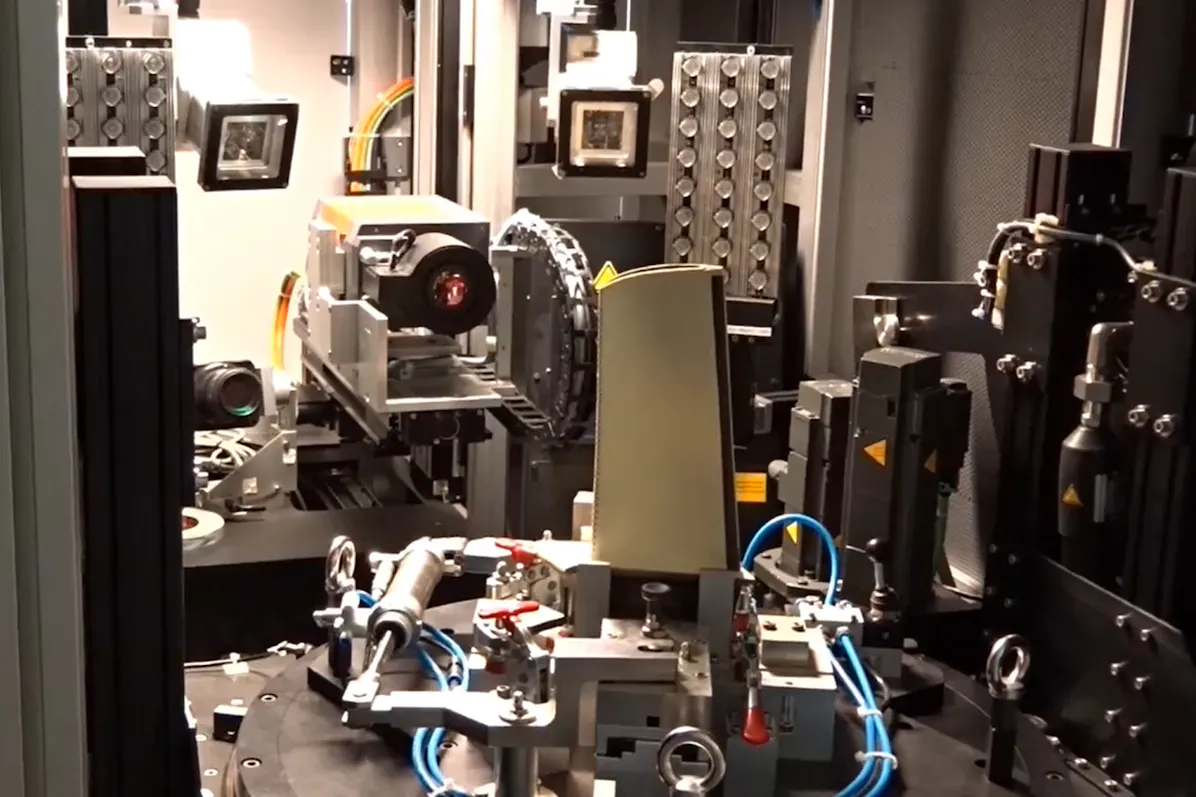

Regardless of how diverse your task is, a thermography automation solution from InfraTec allows you to master the challenge efficiently and cost-effectively. Our proven modular system, consisting of a thermographic camera, transmission, display, interface, industrial PC and software components allows flexible adaptation to your specific requirements.

The core of the turnkey thermography automation solutions are our innovative, robust thermal imaging cameras with detector formats up to (2,560 × 2,048) IR pixels and frame rates into the kilohertz range. In conjunction with our modular hardware and software system, you receive tailored solutions for virtually all fields of industry and research.

Automated thermography solutions from InfraTec provide you with reliable knowledge about even the smallest temperature developments and distributions. Over 30 years of thermal imaging experience and more than 6,000 satisfied customers confirm our competence in this field.

Download Product Flyer

Get all the information you need at a glance in our product flyer.

Your Benefits at a Glance

InfraTec systems have proved effective in practice, are robust and have been designed for continuous industrial operation.

Professional thermographic technology from Germany guarantees you maximum system availability.

You can choose from a wide range of infrared cameras from very compact microbolometer cameras up to cooled high-end cameras with focal plane array photon detectors featuring highest detectivity of (320 × 256) to (2,560 × 2,048) IR pixels and a frame rate of up to 105,000 Hz.

The modular system design offers variability at the highest level and at a good cost-performance ratio.

Your specific requirements determine the subsequent implementation.

Extensive feasibility studies guarantee the lasting success of your investment.

Modern interface concepts enable reliable camera control, data acquisition and online data evaluation even over extremely long distances.

Experienced project engineers support you with the professional installation and commissioning at your premises.

Thermography Systems from InfraTec

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

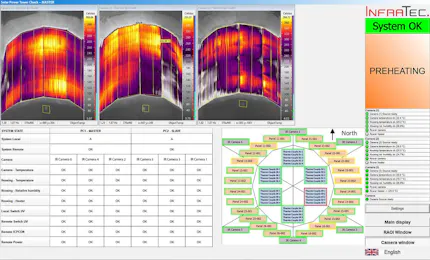

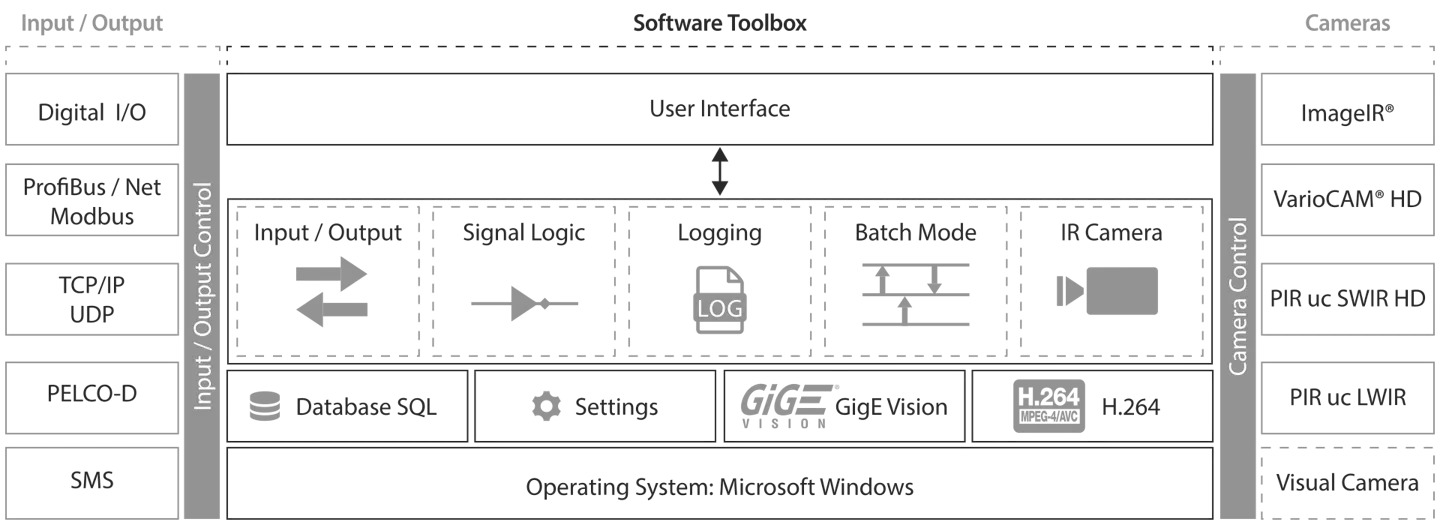

The Software Toolbox for Your Automation Solution

Automation Software from InfraTec

InfraTec's automated thermography solutions provide reliable measurement data. InfraTec developed a special automation software so that these can be analyzed and evaluated by users in a useful way. With extensive analysis and configuration options, the software can be precisely adapted to the individual requirements of the measurement situation and integrated into existing system environments. The application-specific user interface can be operated intuitively.

Flexible integration into the local system structure via universal interfaces and bus systems

Comprehensive representation of results

Reliable alarm release at defined pre and main alarm limits

Customised system alignment and adjustment

Statements of our Customers