Thermography-based OEM Solutions for Industrial Use

Due to their modular basic concept, InfraTec thermography systems can be configured so flexibly that they can also be efficiently integrated into your process solution or product as an OEM solution. You too can integrate InfraTec thermal imaging cameras and gain a competitive edge through precise temperature measurement, even in the machine vision environment.

Integrators Benefit from Numerous Advantages

Application-specific customisability of the systems due to high modularity and professional engineering processes at InfraTec

Accumulated competence from more than 30 years of experience in the application of thermography systems for demanding, customer-specific measurement and inspection tasks

Industrial, flexible interfaces for automation and image processing PCs, compatible with industrial standards such as 10 GigE, GenICam, GigE Vision and Camera Link

Easy plug-and-play integration of thermographic cameras

Fast and seamless integration into existing systems through a powerful SDK (Software Development Kit) and excellent technical support

ITAR-free products

Long-term availability of systems ensures sustainable investment protection

InfraTec as a reliable European partner for development, supply and service

Advantages of Working with InfraTec

Easy Integration in a Direct Way

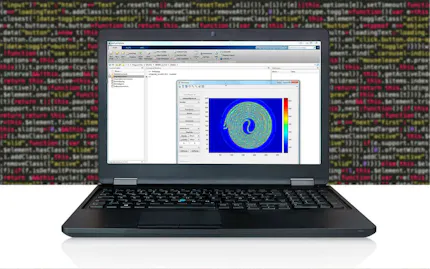

Regardless of the specific application, the decisive factor for OEM partners is, how easily the system can be integrated into the existing environment. InfraTec’s powerful SDK offers best conditions for a convenient integration:

WINDOWS oder LINUX, X86 oder ARM

Recording of real-time thermographic data in various adjustable formats (temperature data in Kelvin, 16-bit digital values, 32-bit bitmap, 8-bit data)

Real-time calculation of temperature values in °C as well as relevant characteristic values such as minimum, maximum, mean value and standard deviation

Operation, control and parameterisation of the thermographic camera via remote access

Optional connections for the development environments LabVIEW and MATLAB

Software development is being conducted at InfraTec's headquarters in Germany

Interfaces for Camera Control and Data Transmission

State-of-art interfaces enable reliable camera control and data acquisition even over very long distances. All InfraTec thermographic cameras are equipped with GigE Vision and industrial GigE compatible interfaces. Alternatively, 10 GigE interfaces can be used. These enable high-speed data transmission at ten times faster transmission speed. Fibre optic versions allow data transmission with high electromagnetic immunity and over extremely long distances in addition. Alternatively, CAMLink interfaces are available for ImageIR® models, too.

Depending on the respective camera model, the following interfaces can be selected:

10 GigE / GigE

CAMLink / DualCAMLink

To ensure that the protection degree of the cameras is maintained even under harsh operating conditions, the connections at our VarioCAM® High Definition are equipped with LEMO® plug connectors that maintain that level of protection.

Reliable Protection Even in Harsh Industrial Environments

An indicator of a thermographic camera durability is always its housing. Therefore, InfraTec attaches great importance to high standards. Closed housings made of high-tensile aluminium alloys with a degree of protection up to IP67 guarantee such standards. Thus, the sensitive sensors and electronics remain protected at all times, even when used in harsh industrial environments.

Suitable protective housings, for example made of stainless steel, are available for applications under extreme environmental conditions. Optionally equipped with cooling and heating, certain models are also certified according to ATEX directives.

First-class Service Ensures High System Availability

From the idea for an OEM solution to the subsequent 24/7 continuous operation of a complete thermographic system, the path leads through numerous stages. InfraTec accompanies integrators from the first step, conducts feasibility studies, develops and produces OEM solutions in cooperation with its partners. Experienced engineers from the in-house service department support users in their daily work with the system and ensure its maintenance.

Our Services in Detail

Multilingual expert support by qualified engineers

24-hour hotline

Rental service for cameras and further equipment

Stock of cameras to cover temporarily shortages

Short service processing times

Calibration in our own laboratory

Thermal Imaging Cameras for a Wide Range of OEM Applications

InfraTec offers OEM partners a wide range of thermal imaging cameras that can be integrated into a wide variety of applications thanks to their modular design. Depending on your requirements, you can choose from different camera categories, all of which impress with their precision, reliability, and ease of integration.

Selection of Possible Applications for OEM

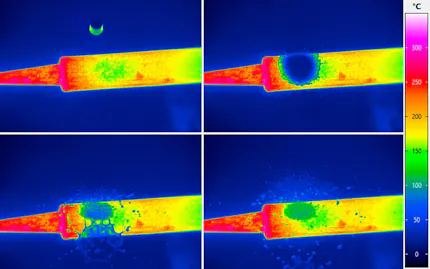

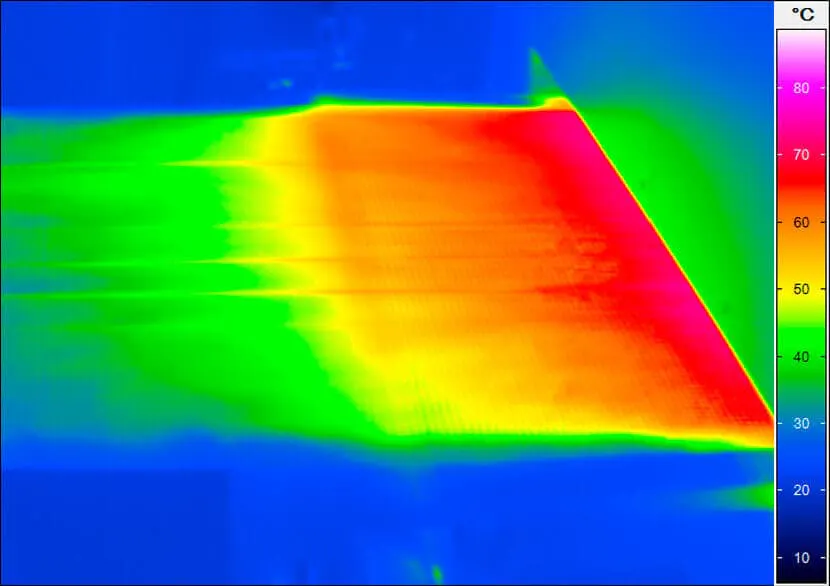

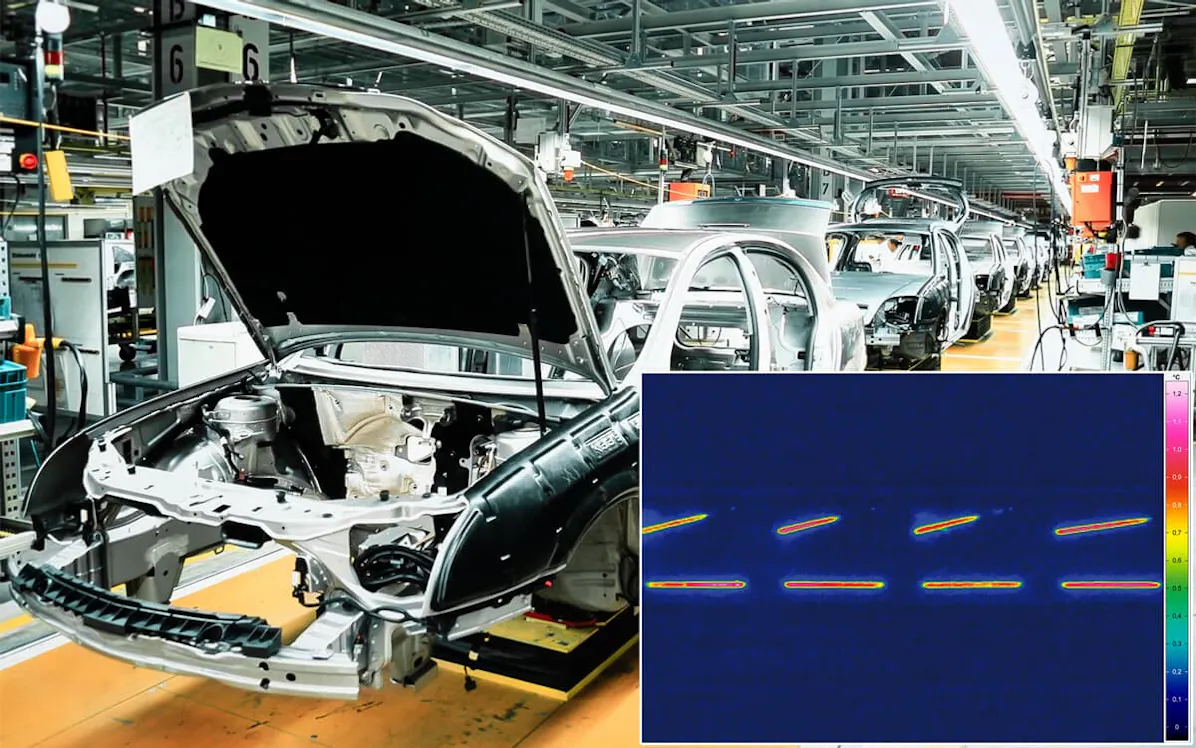

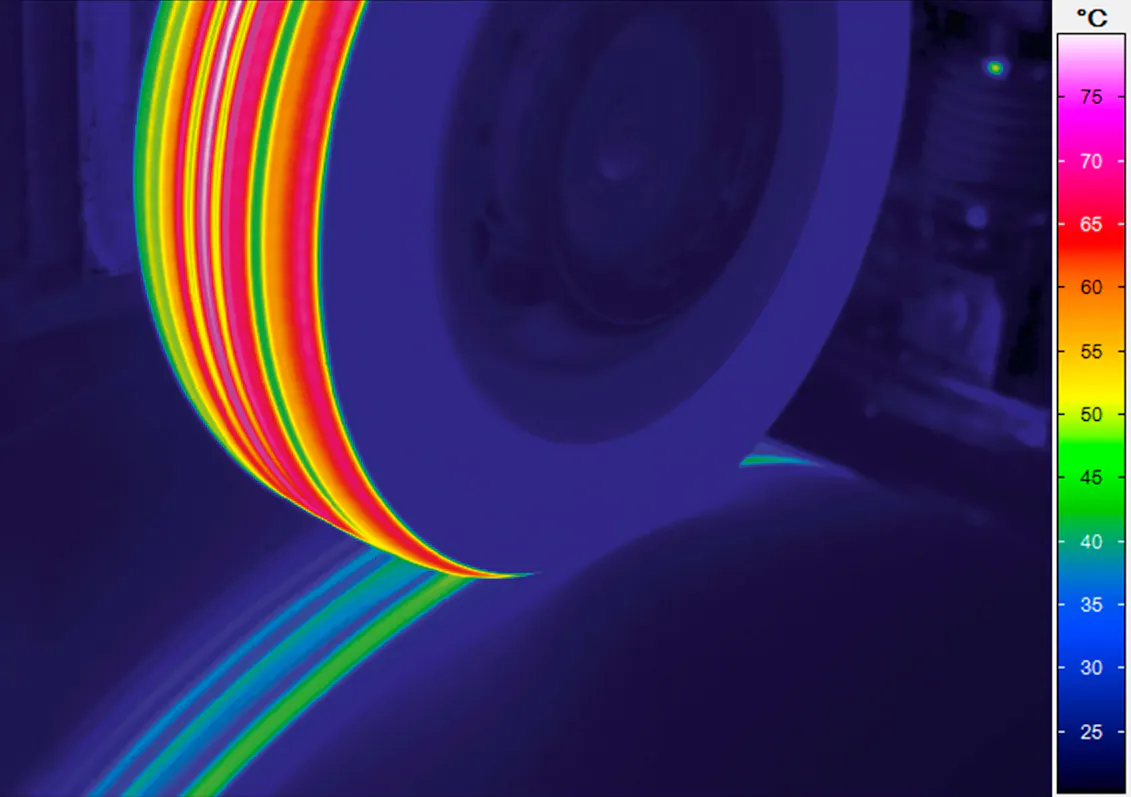

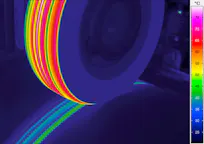

Automation of industrial processes such as quality control and assurance, process control and monitoring, production monitoring

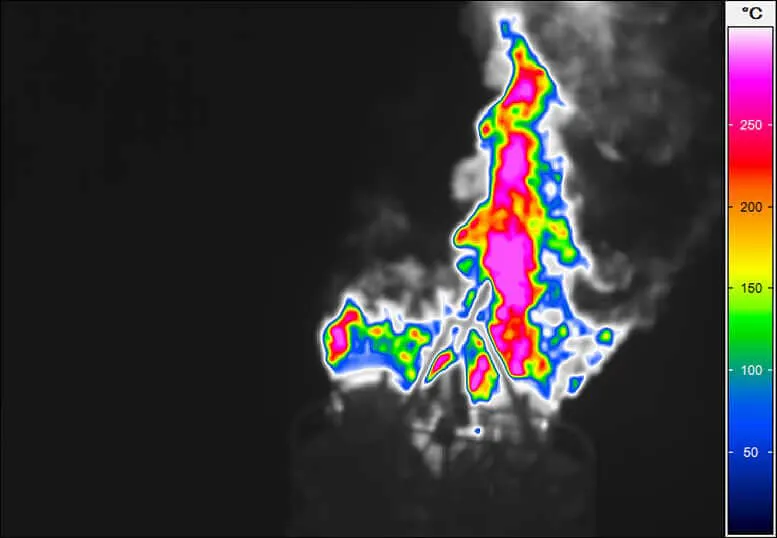

Non-destructive testing such as locating defects in joints and evaluating thermal cutting and spraying processes

Active thermography such as lock-in and pulse-phase thermography for failure detection in assembly and electronic components

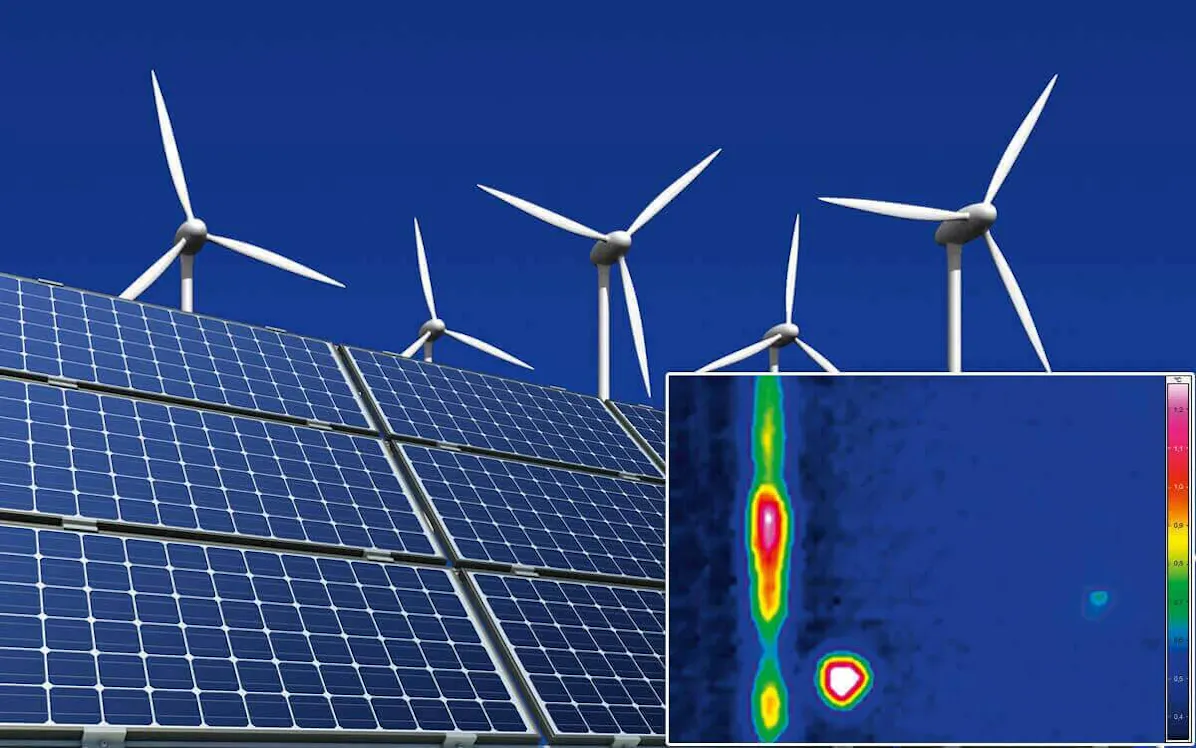

Temperature monitoring at absorbers of solar tower power plants

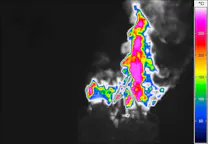

Security applications such as border protection, object surveillance and SAR missions

Gimbal Systems for Helicopter Mounting

InfraTec offers various infrared camera systems for fixed mount use in airplanes as well as for integration into precision gimbals. Thereby, the infrared camera can be exactly positioned within a µrad range to track automatically. A handy remote control allows for camera operation directly via the control of the gimbal.

Gimbals, or gyro-stabilized platforms, have been used for many years as very effective systems for airborne thermography in the inspection of high-voltage power lines, pipelines and industrial plants, as well as in the search for energy and material pollution.

FAQs for Reliability of Supply

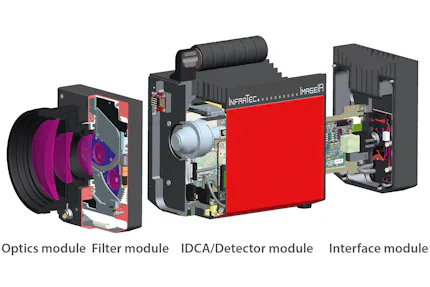

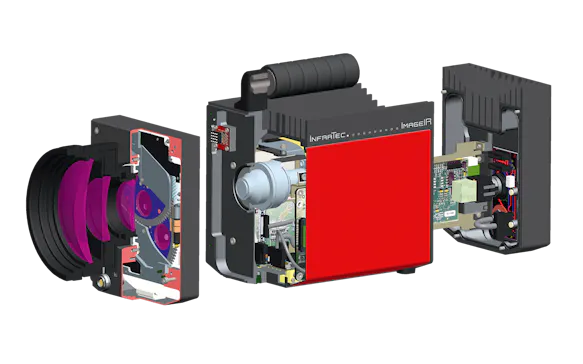

Yes. The high-end infrared cameras of the ImageIR® series are developed and manufactured at InfraTec's headquarters in Dresden. In production, approximately 20 employees configure the modular cameras according to requirements and the specific measurement and testing situation. The selection of the appropriate precision infrared lenses is also carried out at InfraTec. The cameras are calibrated on site using a fully automatic calibration machine.

The high-end infrared cameras of the ImageIR® series are developed and built at the company's headquarters in Dresden. A team of experienced scientists, engineers, and technicians are constantly working to improve the products and open up new areas of application for InfraTec cameras.

The ImageIR® infrared cameras are unique: each of the modular devices is manufactured in a modern production facility according to customer requirements and calibrated on a fully automated calibration stand.

Within Europe, there are no customs or trade restrictions on InfraTec infrared cameras or on the products used by suppliers in their production concerning InfraTecs infrared cameras. Our strategic purchasing and professional supplier management ensure the availability of our infrared cameras at competitive prices.

None of the cameras sold by InfraTec are subject to the International Traffic in Arms Regulations, the US government's regulations for controlling the export and import of defense goods and services. The classification as ITAR-free allows worldwide export, for example to the USA or China.

InfraTec products are used worldwide. The delivery of infrared cameras is organized from the headquarters in Dresden, where experienced employees take care of all formalities such as the preparation of waybills, packing lists, customs declarations, etc., and ensure compliance with import and export regulations. InfraTec relies on established logistics service providers for the transport and delivery of infrared cameras.

Infrared cameras are high-quality, technically complex products. InfraTec supports its customers far beyond the purchase of a thermography system. The in-house service department staff assist users with questions or technical challenges, for example, via remote maintenance. They also recalibrate infrared cameras as needed.

InfraTec offers a comprehensive range of accessories. In the event of a defect, replacement parts can be provided at short notice. In addition, the accessories offer the opportunity to flexibly adapt testing and measurement systems to new and changing tasks.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

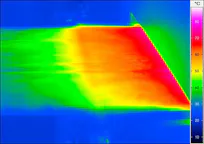

Infrared Thermography – A Smart Temperature Measurement Method with Enormous Potential

Thermal imaging is a passive imaging method for contactless temperature measurement. It uses the fact that every object with a temperature above absolute zero (-273.15 °C) emits electromagnetic radiation. The focal plane array infrared detector of the thermal camera, which is equipped with individual elements arranged in a matrix, uses an optical system to capture the intensity distribution of the radiation emission from the measurement object over a large area. The camera converts the radiation intensities into measured temperature values for each individual pixel of the radiometric thermal image. This results not only in a few temperature readings from individual measurement points, as for example in the case of using thermocouples and pyrometers, but also in hundreds of thousands to millions of temperature readings that are completely distributed over the measurement object.