Thermal Resolution

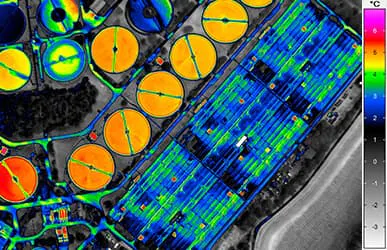

Thermal resolution describes the smallest temperature difference between objects or areas that an infrared camera can reliably resolve. This value – also known as temperature resolution or NETD (Noise Equivalent Temperature Difference) – is a measure of the detector's sensitivity and a key parameter for the performance of an infrared camera.

A higher thermal resolution means that the camera can measure finer temperature differences. In other words, it provides more detailed and reliably evaluable thermal images.

Infrared cameras detect the heat or infrared radiation emitted by a measured object and convert it into an electrical signal. This signal consists of the useful signal and noise.

Signal-to-noise Ratio: A Key Factor for Measurement Accuracy

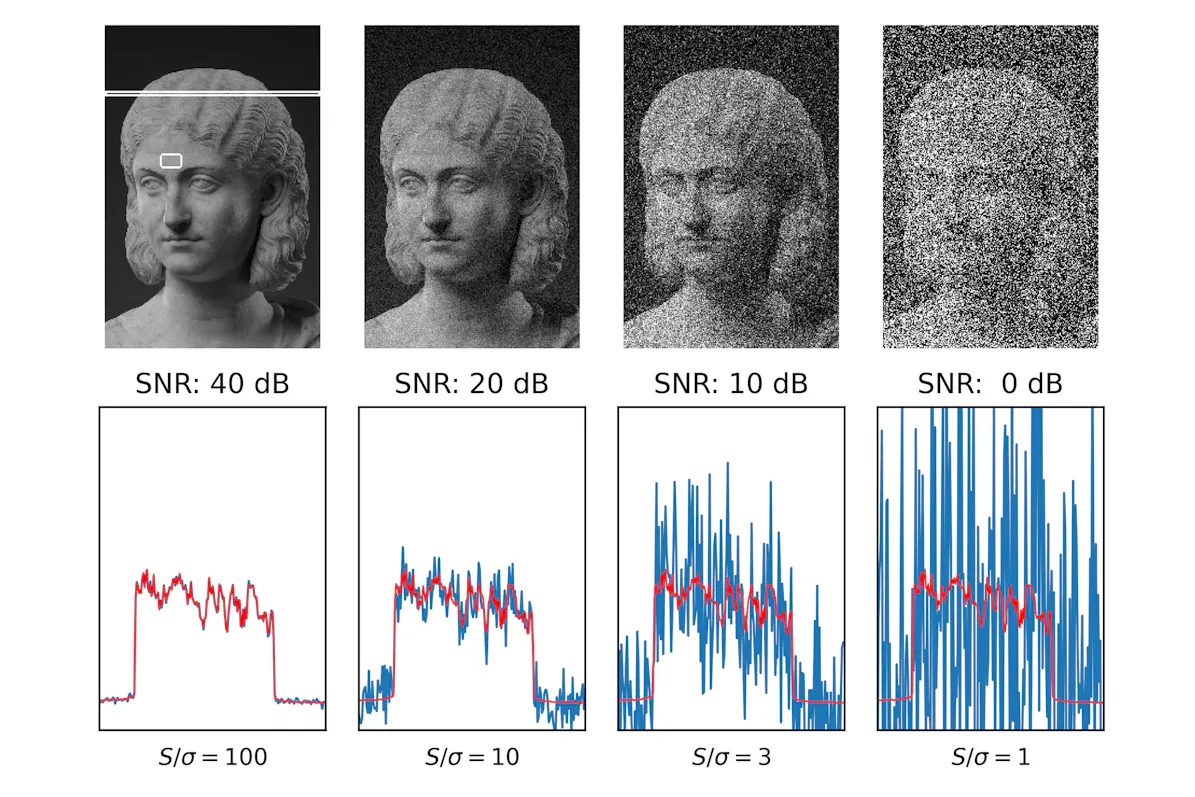

In addition to correct calibration (see below), the signal-to-noise ratio (SNR) plays a crucial role in measurement accuracy. This quality criterion, which is commonly used throughout measurement technology, describes how clearly the useful signal (the desired measurement information) is distinct from the interference signal. These are signal components that arise, for example, due to environmental influences, the internal structure of the camera (for example, heat radiation from the aperture), system properties of the measurement setup (drift), or properties of the detector (noise).

The greater the ratio between the useful signal and the interference signal, the more reliably small temperature differences can be detected and the more informative the measurement. Higher temperatures always generate a higher signal intensity and thus a better signal-to-noise ratio.

Since all bodies above absolute zero (-273.15 °C) emit thermal radiation – including the infrared camera itself – an influence on the measurement result is unavoidable in thermographic measurements, meaning that an objective comparison of different devices is only possible at a reference temperature. Manufacturers usually specify the thermal sensitivity of their infrared cameras for 30 °C.

Example:

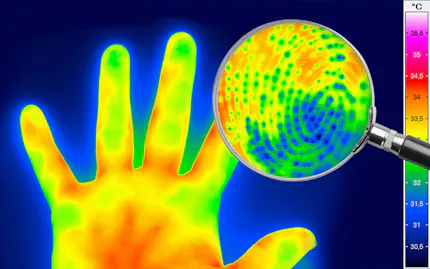

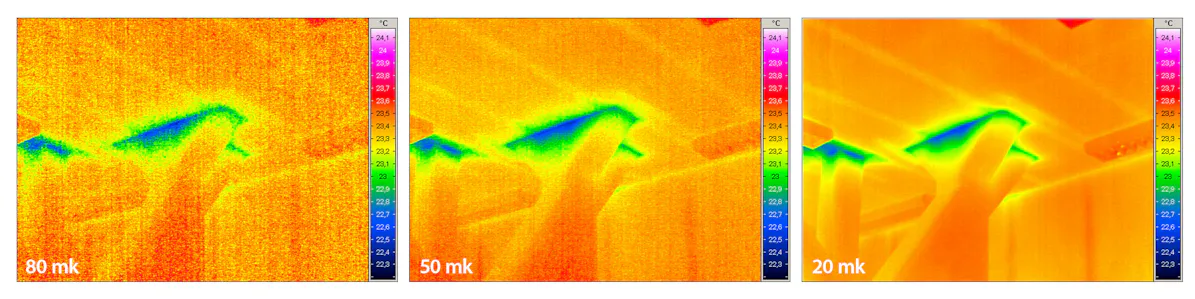

A thermal resolution of 30 mK means that at an object temperature of 30 °C, a temperature difference of 0.03 K (for example, the difference between 29.99 °C and 30.02 °C) can be detected or resolved by the camera and is not masked by the inherent noise of the camera system.

Appropriate Measuring Ranges

For the best results with high thermal resolution, it is recommended to use a thermal imaging camera that measures in the spectral range where the maximum signal from the object's radiation is expected. The temperature and the wavelength at which maximum emission occurs are inversely proportional to each other according to Wien's displacement law. This means that the lower the temperature of the object being measured, the higher the wavelength of maximum emission.

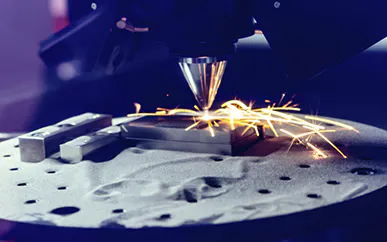

At moderate temperatures (for example, room temperature), it is advisable to use an infrared camera that operates in the long-wave infrared (LWIR) spectral range. For high object temperatures, however, thermal imaging cameras that measure in the short-wave infrared (SWIR) spectral range are more suitable. InfraTec offers solutions for all thermographic measurement tasks.

Calibration Allows for Precise Absolute Temperature Measurement

Infrared cameras are very good at detecting temperature differences – using special methods such as Lock-in Thermography, up to the µK range. However, high thermal resolution alone is not sufficient for accurate temperature measurement. The camera and lenses used must be carefully calibrated for the respective temperature range.

At InfraTec, radiometric calibration is standard, i.e., absolute temperature measurement is possible with all infrared cameras.

High Thermal Resolution

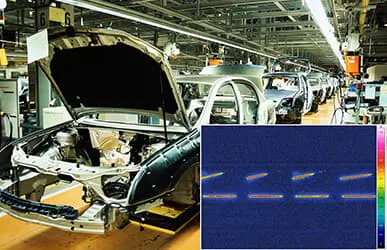

High thermal resolution is particularly important when even the smallest temperature differences can indicate defects and faults or anomalies. Typical applications include:

Troubleshooting electronic components

Material testing in research and development

Quality control in industry and aerospace

Medical diagnostics

Determinants of Thermal Resolution

Thermographic measurement quality depends on various factors.

These include:

Type and quality of the IR sensor implemented

Spectral sensitivity range of the camera

Optical design (lens material, coating, aperture (F/1))

Internally used image processing algorithms (special filters, image accumulation, shutter regime)

Measurement ranges (integration times, apertures, gray filters)

Advantages of InfraTec Infrared Cameras

InfraTec's cooled and uncooled camera systems offer maximum thermal resolution – a decisive advantage for precise measurement results and reliable analyses. Even at low object temperatures with low signal intensity, they enable noise-free and detailed thermograms with excellent image homogeneity.

Overview of advantages:

Thermal resolution of 0.015 K (15 mK) – reliable detection of even the smallest temperature differences on the measurement object

High-precision absolute measurement with a measurement accuracy of ±1 °C or ±1 % thanks to complex radiometric calibration

Noise-free, detailed visualization, revealing the finest temperature variations, even at low temperatures

Outstanding image quality thanks to fast and precise infrared optics

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Send request