Inspections of Electrical Installations

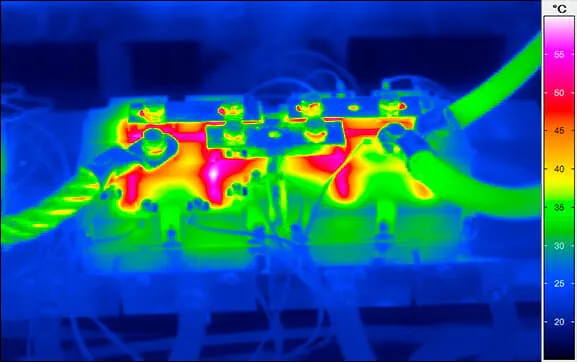

Thermal imaging provides a fast overview of the conditions of electrical installations

Hot-spots are a good indicator for faults when doing comparative thermography

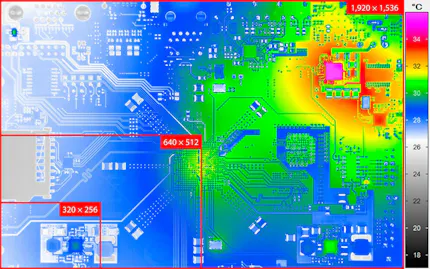

Reliable detection of hot-spots requires a sufficiently high number of pixels

During thermographic measurements load conditions have to be kept in mind

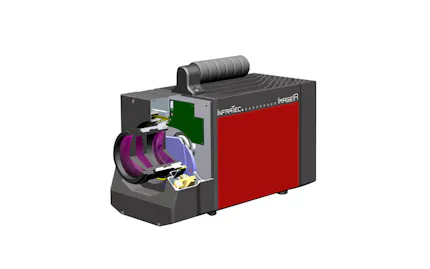

Important flexibility of infrared camera systems is reached by interchangeable lenses

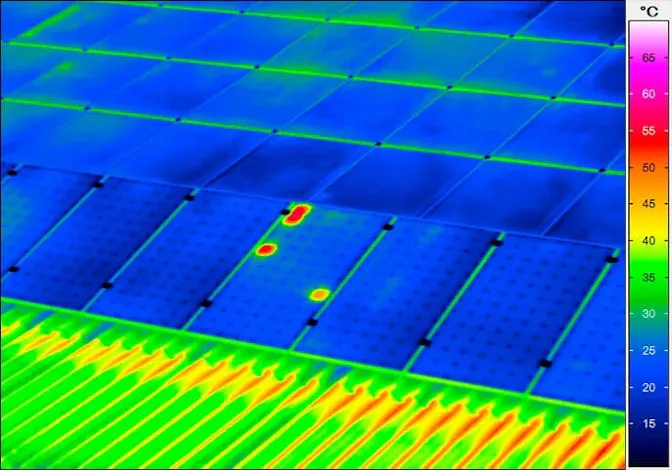

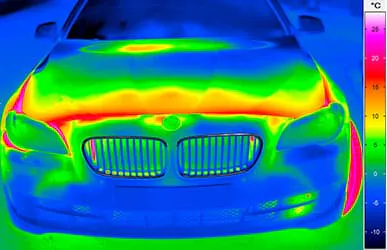

Qualitative Thermography Allows Easy Inspections

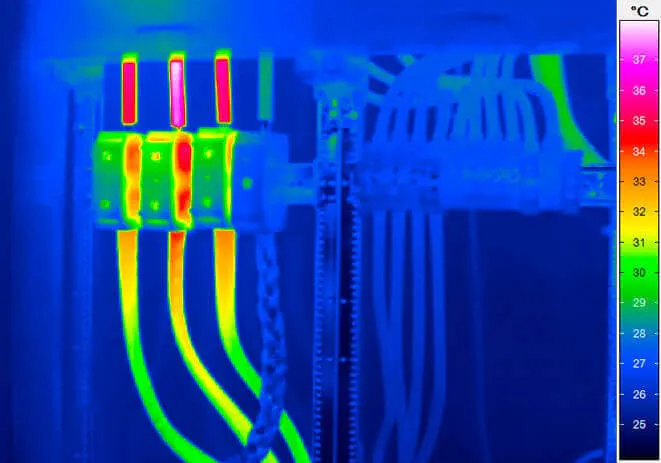

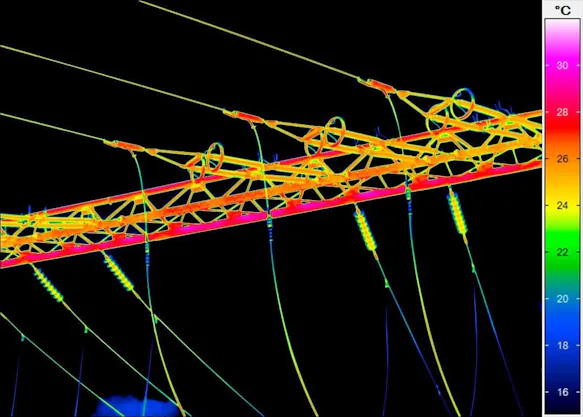

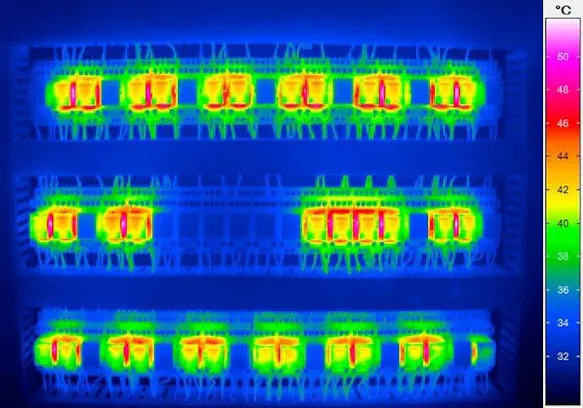

Inspections of electrical installations mostly focus on the detection of hot-spots – areas with excessive temperatures. Those can often be found by comparison of the same kind of components just having different temperatures. For example one phase can have a higher temperature in comparison with other phases due to a poor insulation which results in a creeping current. Already such a comparative analysis called qualitative thermography is absolutely sufficient in many inspection situations.

Faults Can Only Be Identified by Having a Sufficient Number of Pixels

To provide a secure conclusion the infrared camera being used needs to come with an adequate resolution. Inspecting electrical installations especially the geometrical resolution should be focused on which is the number of pixels being available for the measurement. The more available pixels, the smaller are the hot-spots which can be detected from a certain distance and the earlier a developing fault can be discovered, resulting in a more secure inspection result. An infrared camera with a correspondingly large detector format therefore does not determine average values from hotspot temperatures and lower ambient temperatures. This would rather prevent the reliable detection of a hotspot.

Temperature Measurements are Influenced by Load Situation of Electrical Installations

Very important for thermographic analyses of electrical installations is their load behaviour. When thermographic measurements are done in low load situations hot-spots will not be detectable securely as those areas will appear a lot colder than running at full load. Therefore either the measurements will be done at full load or the measured lower temperatures will be converted to those which would be measured when running at full load.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

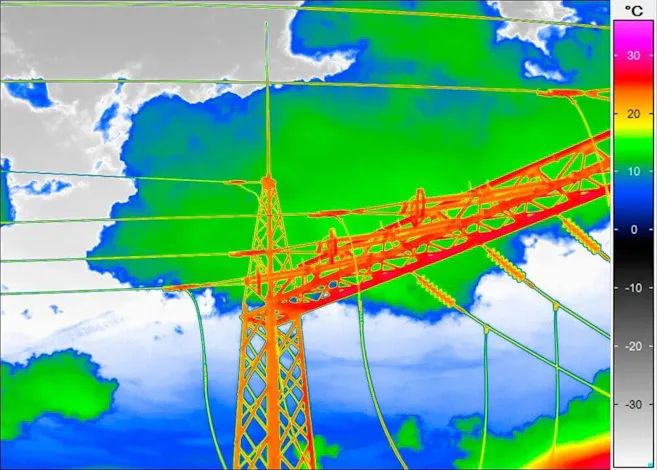

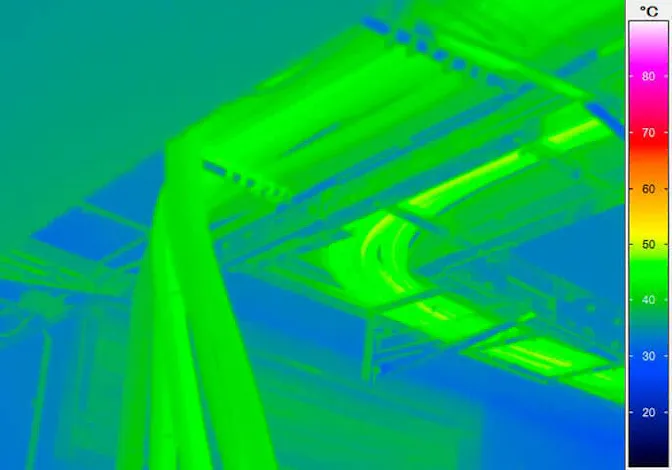

Interchangeable Lenses Allow the Flexible Usage of Infrared Camera Systems

Very often thermography is used for controlling high voltage installations outdoors. To do those measurements correctly measuring smallest details full signal telephoto lenses should be used. In contrast limited space indoors could well result in the need to use wide-angle lenses for coverage of complete switchboards.