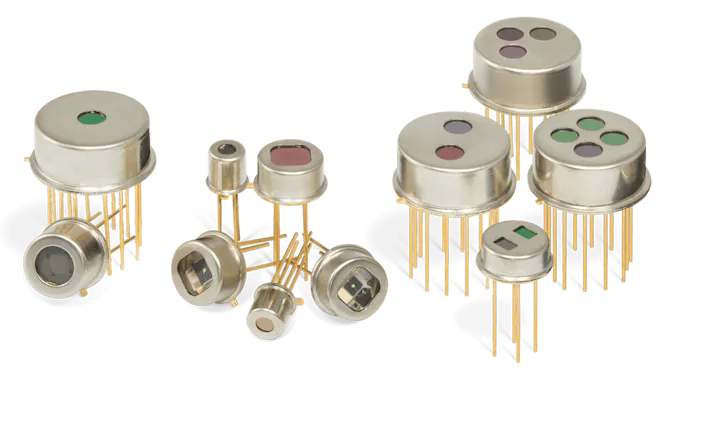

PYRONEER – High-Performance Detectors

InfraTec's PYRONEER detectors based on lithium tantalate (LiTaO3) or deuterated L-alanine doped triglycine sulphate (DLaTGS) have been developed for use in analytical instruments and spectroscopy. The precious metal black layer applied to the pyroelectric element guarantees homogenous absorption behavior in a wide spectral range.

Type | close Number of measuring channelsNumber of Channels | close TO18, TO46: 5.4 mm in diameter Housing | close Size of the circular or rectangular aperture through which radiation hits the sensitive elements.Aperture (mm) | close Voltage Mode: The pyroelectric current is initially converted into a voltage by an RC network followed by a conversion to lower impedance. Current Mode: The pyroelectric current is permanently compensated by an OpAmp. The current required for this generates a voltage drop across an RC network in the feedback path which serves as the measurement signal. Operating Mode | close Integrated signal condition like integrated junction field effect transistors (JFET) for detectors in voltage mode or integrated operational amplifiers (OpAmp) for detectors in current mode. Amplifier | close A pyroelectric detector is sensitive to changes in temperature. Changes in ambient temperature have an influence on the measurement signal and shifts the operating point. This effect reduces a thermal compensation. Therefore, each pyroelectric element gets an additional optically inactive element, which compensates for unwanted currents. Thermal Compensation | close Patented micromechanical chip attachment (LowMicro) by InfraTec to reduce the effects of interfering impact sounds. Low Micro | close As a key parameter, the specific detectivity D* characterizes the signal-to-noise ratio of infrared detectors. Specific Detectivity* | |

|---|---|---|---|---|---|---|---|---|---|

LIE-312 close 1Hz ... 4kHz, metal black coating | 1 | TO39 | ø 5.0 | Voltage Mode | JFET | 1.6 ** | |||

LIE-312f close 10Hz ... 4kHz, metal black coating | 1 | TO39 | ø 5.0 | Voltage Mode | JFET | 1.3 ** | |||

LIE-332f close 10Hz ... 4kHz, metal black coating | 1 | TO39 | ø 5.0 | Voltage Mode | JFET | 1.3 ** | |||

DSV-7311 close single channel; TO39 housing; small chip size; JFET; voltage mode; DLaTGS - Deuterated L-Alanine doped TriGlycine Sulphate; short thermal time constant, metal black coating | 1 | TO39 | ø 5,5 | Voltage Mode | JFET | 3.3 **** |

* in 10

** in 10

*** bei R

**** in 10

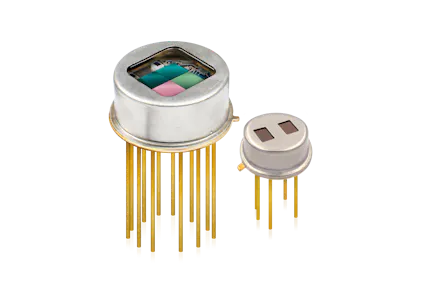

DSV-7311 – The First DLaTGS Detector of the PYRONEER Series

The newest member of the PYRONEER product series is the high-performance detector DSV-7311. This detector with a pyroelectric element based on DLaTGS is an extraordinary performer:

Single channel detector in TO39 housing

One pyroelectric element with a diameter of 1.3 mm

Voltage mode with low-noise junction field effect transistor (JFET)

Specific detectivity (D*) of 3.3×10

8 Jones at 1 kHzThermal time constant of 12 milliseconds

Field of View (FOV) of 110°

LiTaO3-Detectors (Type LIE)

Pyroelectric detectors for analytical devices have been part of the InfraTec portfolio for over 20 years. to the InfraTec portfolio. The first detectors in this series were based exclusively on high-quality, single-crystalline lithium tantalate (LiTaO3). This material offers a robust and reliable detector performance with a very low temperature coefficient and excellent long-term stability. With a precious metal black layer on the pyroelectric elements specially adapted for these detectors, they meet the highest requirements that are common in FTIR spectroscopy.

DLaTGS-Detectors (Type DSV)

The DLaTGS detectors are a real performance boost for FTIR spectroscopy. Based on the high-performance, pyroelectrically sensitive material DLaTGS (deuterated L-alanine doped triglycine sulphate), these detectors are clearly superior to LiTaO3 detectors with a triple detectivity (D*) at modulation frequencies in the kHz range. This combination of high pyroelectric coefficient, low heat capacity and low relative permittivity meets all requirements for achieving very good signal-to-noise ratios at very high modulation frequencies.

In Fourier transform infrared spectrometers (FTIR) they are considered the gold standard among infrared detectors.

LiTaO3 vs. DLaTGS – Features in Comparison

| Detector | PYRONEER LiTaO3 | PYRONEER DLaTGS |

| Detector series | LSV, LIE-312(f), LIE-332(f) | DSV |

| Pyroelectric material | Lithium tantalate (LiTaO3) | Deuterated L-Alanine doped Tri-Glycine-Sulfate (DLaTGS) |

| D* Detectivity | + | +++ |

| Flat spectral response (2 ... 10 µm) | +++ | +++ |

| Thermal stabilization | No | In development |

| Operating mode | Voltage mode | Voltage mode |

| Active area | Ø 1.3 mm, Ø 2.0 mm | Ø 1.3 mm, further formats in development |

| Package | TO39 | TO39 |

| Response time | + | ++ |

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our experienced engineers, receive further technical information or learn more about our additional services.

One-stop Solution

The production process for the DLaTGS detectors takes place from start to finish at InfraTec's headquarters in Dresden:

Growing the sensitive DLaTGS crystal material

Preparation of DLaTGS sensor elements

Assembly of the detector with applying the precious metal black layer

Thanks to its modular design, the Pyroneer series can be flexibly adapted to your application-specific requirements.

For a Clear View

When selecting the entrance windows for the detectors, a wide range of materials is available that are characterized by consistently high transmission over a wide wavelength range. Up to now, they have been available with an optional anti-reflective coating:

Barium fluoride

Potassium bromide

Caesium iodite

Zinc selenid*

* Zinc selenide windows with an antireflection coating (ARC) are a good alternative for particularly harsh environments. ZnSe is inherently more resistant to moisture than KBr. Soldering the ZnSe window into the detector cap also creates a hermetically sealed connection, preventing moisture from entering the detector.

Learn more about Soldered ZnSe ARC window

In the future, InfraTec will also offer window materials that possess good transmission properties in the far infrared (FIR) and terahertz range. In particular, CVD diamond and polyethylene should be highlighted here.

Detector Search

InfraTec offers different product groups including approximately 50 standard pyroelectric detectors. Detectors with reduced microphone technology and integrated operational amplifier as well as digital detectors are part of our product range.

Choose your suitable infrared detectors with the help of our detailed detector search.