InfraTec Detector and Filter Overview

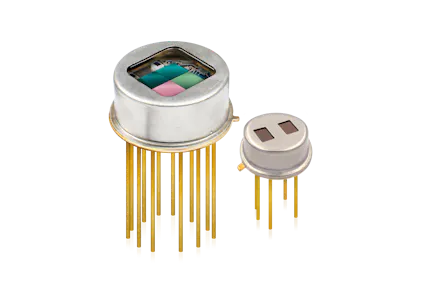

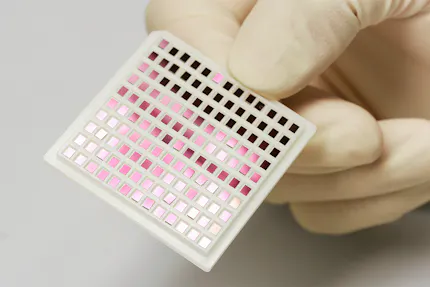

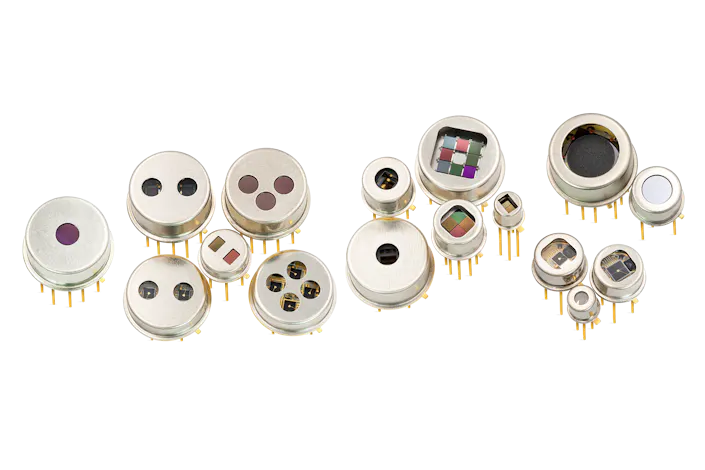

The modular construction system of InfraTec’s pyroelectric detectors consists of approximately 50 standard types and therefore offers optimized solutions for a variety of applications in the field of sensor technology. Detectors with reduced microphone technology and integrated operational amplifier as well as digital detectors are part of our product range.

Type | Product Group | close Number of measuring channelsNumber of Channels | close TO18, TO46: 5.4 mm in diameter Housing | close Size of the circular or rectangular aperture through which radiation hits the sensitive elements.Aperture (mm) | close Voltage Mode: The pyroelectric current is initially converted into a voltage by an RC network followed by a conversion to lower impedance. Current Mode: The pyroelectric current is permanently compensated by an OpAmp. The current required for this generates a voltage drop across an RC network in the feedback path which serves as the measurement signal. Operating Mode | close Integrated signal condition like integrated junction field effect transistors (JFET) for detectors in voltage mode or integrated operational amplifiers (OpAmp) for detectors in current mode. Amplifier | close A pyroelectric detector is sensitive to changes in temperature. Changes in ambient temperature have an influence on the measurement signal and shifts the operating point. This effect reduces a thermal compensation. Therefore, each pyroelectric element gets an additional optically inactive element, which compensates for unwanted currents. Thermal Compensation | close Patented micromechanical chip attachment (LowMicro) by InfraTec to reduce the effects of interfering impact sounds. Low Micro | close As a key parameter, the specific detectivity D* characterizes the signal-to-noise ratio of infrared detectors. Specific Detectivity* | |

|---|---|---|---|---|---|---|---|---|---|---|

New | PyrIQ - Digital Detectors | 4 | TO8 | 8.5 x 8.5 | Current Mode | PyrIQ | 2.4 *** | |||

New | PyrIQ - Digital Detectors | 2 | TO39 | ø 6.0 | Current Mode | PyrIQ | 1.5 *** | |||

| Single Channel Detectors | 1 | TO18 / TO46 | ø 2.3 | Current Mode | JFET | 0.55 | ||||

| Single Channel Detectors | 1 | TO18 / TO46 | ø 2.3 | Voltage Mode | JFET | 4.0 | ||||

| Single Channel Detectors | 1 | TO18 / TO46 | ø 2.3 | Voltage Mode | JFET | 3.0 | ||||

| Single Channel Detectors | 1 | TO39 | 5.0 x 5.0 | Voltage Mode | JFET | 4.0 | ||||

| Single Channel Detectors | 1 | TO39 | 5.0 x 5.0 | Voltage Mode | JFET | 6.0 | ||||

| Single Channel Detectors | 1 | TO39 | 5.0 x 5.0 | Voltage Mode | JFET | 4.0 | ||||

| Single Channel Detectors | 1 | TO39 | 5.0 x 5.0 | Current Mode | OpAmp | 6.0 | ||||

LME-336 close Single supply operation | Single Channel Detectors | 1 | TO39 | 5.0 x 5.0 | Current Mode | OpAmp | 4.0 | |||

| Single Channel Detectors | 1 | TO39 | 5.0 x 5.0 | Current Mode | OpAmp | 1.8 | ||||

LME-352 close Single supply operation | Single Channel Detectors | 1 | TO39 | 5.0 x 5.0 | Current Mode | OpAmp | 1.5 | |||

| Single Channel Detectors | 1 | TO39 | 5.0 x 5.0 | Current Mode | none | - | ||||

| Single Channel Detectors | 1 | TO39 | 5.0 x 5.0 | Current Mode | OpAmp | 2.5 | ||||

LRM-274 close Single supply operation | PYROMID® Multi Channel Detectors | 4 | TO8 | 8.5 × 8.5 | Current Mode | OpAmp | 4.0 | |||

New LRM-278 close single supply operation | PYROMID® Multi Channel Detectors | 8 | TO8 | 8.5 x 8.5 | Current Mode | OpAmp | 4.5 | |||

LIM-032 close Integrated Beam Splitter | PYROMID® Multi Channel Detectors | 2 | TO39 | 2.8 x 2.8 | Voltage Mode | JFET | 2.9 | |||

LIM-011 close Integrated Beam Splitter | PYROMID® Multi Channel Detectors | 4 | TO8 | 2.8 x 2.8 | Voltage Mode | JFET | 0.8 | |||

LIM-054 close Integrated Beam Splitter | PYROMID® Multi Channel Detectors | 4 | TO8 | 2.8 x 2.8 | Current Mode | OpAmp | 0.42 | |||

New LIM-082 close Integrated Beam Splitter | PYROMID® Multi Channel Detectors | 2 | TO39 | 2.8 x 2.8 | Current Mode | OpAmp | 1.9 | |||

| PYROMID® Multi Channel Detectors | 2 | TO18 / TO46 | 3.0 x 2.0 | Voltage Mode | JFET | 4.0 | ||||

| PYROMID® Multi Channel Detectors | 2 | TO18 / TO46 | 3.0 x 2.0 | Voltage Mode | JFET | 2.0 | ||||

| PYROMID® Multi Channel Detectors | 4 | TO39 | 5.0 x 5.0 | Voltage Mode | JFET | 4.7 | ||||

LRM-284 close Single supply operation | PYROMID® Multi Channel Detectors | 4 | TO39 | 5.0 x 5.0 | Current Mode | OpAmp | 4.5 | |||

LRM-244 close single supply operation | PYROMID® Multi Channel Detectors | 4 | TO8 | 8.5 x 8.5 | Current Mode | OpAmp | 6.0 | |||

New | PYROMID® Multi Channel Detectors | 2 | TO18 / TO46 | 3.0 x 2.0 | Current Mode | OpAmp | 3.0 | |||

| Planar Multi Channel Detectors | 2 | TO39 | ø 6.0 | Voltage Mode | JFET | 4.5 | ||||

| Planar Multi Channel Detectors | 2 | TO39 | ø 6.0 | Current Mode | OpAmp | 4.5 | ||||

LIM-272 close Single supply operation | Planar Multi Channel Detectors | 2 | TO39 | ø 6.0 | Current Mode | OpAmp | 3.0 | |||

| Planar Multi Channel Detectors | 4 | TO8 | ø 9.5 | Current Mode | OpAmp | 5.0 | ||||

LMM-274 close Single supply operation | Planar Multi Channel Detectors | 4 | TO8 | ø 9.5 | Current Mode | OpAmp | 5.0 | |||

New LSV-9313 close single channel; TO39 housing; medium chip size; JFET; voltage mode; short time constant, metal black coating | PYRONEER - High-Performance Detectors | 1 | TO39 | ø 5,5 | Voltage Mode | JFET | 1.3 ** | |||

New DSV-7311 close single channel; TO39 housing; small chip size; JFET; voltage mode; DLaTGS - Deuterated L-Alanine doped TriGlycine Sulphate; short thermal time constant, metal black coating | PYRONEER - High-Performance Detectors | 1 | TO39 | ø 5,5 | Voltage Mode | JFET | 3.3 **** | |||

LIE-312 close 1Hz ... 4kHz, metal black coating | PYRONEER - High-Performance Detectors | 1 | TO39 | ø 5.0 | Voltage Mode | JFET | 1.6 ** | |||

LIE-312f close 10Hz ... 4kHz, metal black coating | PYRONEER - High-Performance Detectors | 1 | TO39 | ø 5.0 | Voltage Mode | JFET | 1.3 ** | |||

LIE-332f close 10Hz ... 4kHz, metal black coating | PYRONEER - High-Performance Detectors | 1 | TO39 | ø 5.0 | Voltage Mode | JFET | 1.3 ** |

* in 10

** in 10

*** bei R

**** in 10

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our experienced engineers, receive further technical information or learn more about our additional services.