From Engineering Consultancy to Global Organization

Over the past 35 years, InfraTec has established itself as one of the leading providers of commercial thermal imaging technology with its infrared measurement technology division. The portfolio includes high-quality thermographic cameras for research and development, cameras for thermography-based OEM applications, and turnkey, automated system solutions for industrial thermographic temperature measurement.

From Vision to Market Leader

In 1990, Dr. Matthias Heinze and Dr. Matthias Krauß, the two Managing Directors of InfraTec, founded an engineering consultancy that has since evolved into the company we know today. The official anniversary of InfraTec GmbH Infrarotsensorik und Messtechnik is 24 June 1991, the date the company was entered in the Dresden Commercial Register.

The young company quickly made its mark in the market by producing and selling compact multicolor gas detectors, as well as offering pyrometric and thermographic temperature measurement technology. Today, InfraTec employs over 240 people worldwide across two business divisions.

While the Sensor Technology division develops, manufactures, and worldwide sells custom infrared detectors, the Infrared Measurement Technology division has established the company as one of the leading suppliers of commercial thermal imaging technology. The portfolio includes high-quality thermographic cameras for research and development, cameras for thermography-based OEM applications, and turnkey, automated system solutions for industrial thermographic temperature measurement.

Early Innovations That Set New Standards

As early as 1996, InfraTec installed its first automated thermographic early fire detection system in the storage bunkers of waste incineration plants (FIRE-SCAN). Today, this type of solution is also used, for example, to monitor the production and storage of lithium-ion batteries. The current project business also encompasses a range of solutions for process and quality control within the industrial automation sector. In addition, solutions are available for non-destructive thermographic testing in quality assurance and development, as well as for efficient monitoring of inaccessible or expansive sites.

InfraTec has been offering a powerful thermography software family under the brand IRBIS® since 1998, with the benefit of universal use and ongoing in-house development. Whether for 24/7 process monitoring or complex tasks such as lock-in thermography tests, IRBIS® software manages the acquisition of temperature data and reliably analyzes the information. All processes are tailored to each customer’s specific requirements.

Research and Development at the Core

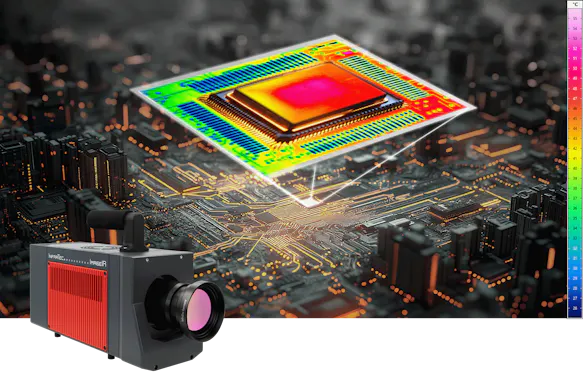

From the outset, InfraTec has continuously invested in research and development at its Dresden site. As early as 2012, the company was able to offer thermographic cameras with cooled detectors in megapixel format. In 2014, the portfolio was expanded to include the first infrared cameras featuring a super-zoom lens and HD resolution. In 2016, InfraTec introduced the ImageIR® 10300, a radiometrically calibrated thermal imaging camera featuring the largest geometric resolution available on the market (1,920 × 1,536 IR pixels), enabling full HD recording for the first time. Now, the former frontrunner has been replaced by the 5.2 megapixel ImageIR® 12300 camera with (2,560 × 2,048) IR pixels.

The introduction of uncooled radiometric zoom cameras in 2018 significantly broadened the application range of InfraTec’s thermographic systems. In 2019, the cameras were upgraded with new features, including high-speed recording with frame rates of up to 105 kHz (subwindowing) and a fourfold increase in resolution (MicroScan). In 2020 and 2023, cooled cameras with innovative new detector technologies were introduced to enhance performance and improve long-term operational reliability. Since 2024, InfraTec thermographic cameras have been equipped with high-performance electronics featuring a large processing bandwidth and an integrated operating system, ensuring autonomous operation even for complex and time-critical measurement tasks.

From Standard Applications to High-End Solutions

While InfraTec’s Infrared Measurement Technology initially focused on standard applications such as building thermography and preventive maintenance with simple mobile devices, the company now specializes in high-quality stationary thermography cameras for complex and demanding applications. The high-end cameras of the ImageIR® series are developed and manufactured at InfraTec's headquarters in Dresden. During assembly, our employees configure the modular devices to meet customer requirements and the applicable measurement or testing conditions. After assembly with the precision infrared lenses manufactured specifically for InfraTec and other accessories, the devices undergo commissioning and endurance testing using a stress test. The subsequent precise adjustment of the thermographic cameras on automated calibration stands ensures high measurement accuracy and traceability to recognized temperature measurement standards, as documented by the corresponding calibration certificates. Finally, the systems undergo a comprehensive initial test before being delivered to customers worldwide.

A Portfolio Designed for Maximum Flexibility

With the ImageIR® series and the TarisIR® and VarioCAM® product families, InfraTec provides state-of-the-art, high-performance solutions for all areas of infrared thermography. Whether for research and development, industrial process and quality control, or reliable object monitoring, more than 30 models with numerous equipment variants ensure customers enjoy maximum flexibility.