![Sales Manager East Justin Jensen Sales Manager East Justin Jensen]() 2020-02-25More Service for Customers in North AmericaInfraTec sales team strengthened by infrared technology expertRead onDownload ZIP-File (6801 kB)

2020-02-25More Service for Customers in North AmericaInfraTec sales team strengthened by infrared technology expertRead onDownload ZIP-File (6801 kB)Given the widespread success of its pyroelectric detectors in the USA, Canada and Mexico, InfraTec is expanding its local presence. Justin Jensen will be joining the team as new Sales Manager East.

![InfraTec thermography pr hdr InfraTec thermography pr hdr, picture credit: © iStock.com / vershinin-M]() 2020-02-13Simultaneous Mapping of Wide Temperature RangesThe HDR function of the high-end camera series ImageIR® facilitates the analysis of objects with extreme temperature gradientsRead onDownload ZIP-File (11518 kB)

2020-02-13Simultaneous Mapping of Wide Temperature RangesThe HDR function of the high-end camera series ImageIR® facilitates the analysis of objects with extreme temperature gradientsRead onDownload ZIP-File (11518 kB)If you want to measure temperatures in a very wide range with an infrared camera, you normally do this in stages. The neutral density filters are changed gradually from time to time. Adjusted to a specific temperature range, they prevent high-intensity infrared radiation from striking the camera detector and falsifying the measurement result by depolarising the detector pixels.

![Infrared camera series ImageIR® 9400 from InfraTec Infrared camera series ImageIR® 9400 from InfraTec]() 2020-01-27Versatile and Extremely PowerfulFull of Technical Innovations: ImageIR® 9400 from InfraTec - the All-round Talent among High-end Thermography SystemsRead onDownload ZIP-File (2015 kB)

2020-01-27Versatile and Extremely PowerfulFull of Technical Innovations: ImageIR® 9400 from InfraTec - the All-round Talent among High-end Thermography SystemsRead onDownload ZIP-File (2015 kB)Measurement and testing tasks that use infrared cameras often differ enormously. So what could be better than being able to use a camera that is exactly tailored to the specific application? Quite clearly, a camera that can solve very different tasks at the highest possible level.

![InfraTec Uni Bayreuth - Analysis of the Thermal Conductivity InfraTec Uni Bayreuth - Analysis of the Thermal Conductivity]() 2020-01-23Case Study: Analysis of the Thermal Conductivity in Nano- and Mesostructured Polymer SystemsLock-in Thermography with Infrared Camera VarioCAM® HD research 800Read onDownload PDF-File (943 kB)

2020-01-23Case Study: Analysis of the Thermal Conductivity in Nano- and Mesostructured Polymer SystemsLock-in Thermography with Infrared Camera VarioCAM® HD research 800Read onDownload PDF-File (943 kB)New materials with precisely controlled optical and thermal transport characteristics can make a large contribution to resource-saving thermal management. Scientists of the University of Bayreuth are pursuing this vision.

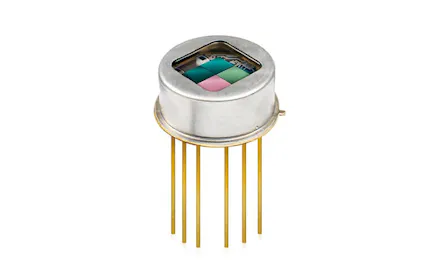

![PYROMID® multi channel detector LRM-274 from InfraTec PYROMID® multi channel detector LRM-274 from InfraTec]() 2020-01-20More Performance, Less PowerThe LRM-274 from InfraTec is ideal for integration into flame sensor measurement instrumentsRead onDownload ZIP-File (4876 kB)

2020-01-20More Performance, Less PowerThe LRM-274 from InfraTec is ideal for integration into flame sensor measurement instrumentsRead onDownload ZIP-File (4876 kB)When organic substances such as wood, natural gas, petrol and various plastics are catching fire, spectral radiation of typical wavelengths is emitted. As a specialist in flame detection technology, InfraTec is expanding its range of specialized detectors that detect radiation in precisely this area. The new miniaturized multi channel detector LRM-274 is characterized by the fact that as a low-power detector it requires only one unipolar supply voltage.