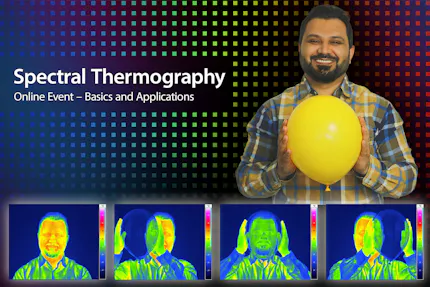

![Spectral Thermography – Basics and Application Spectral Thermography – Basics and Application]() 2024-09-10Online Event: “Spectral Thermography – Basics and Applications”Precision measurement using spectral IR thermographyRead onDownload ZIP-File (10174 kB)

2024-09-10Online Event: “Spectral Thermography – Basics and Applications”Precision measurement using spectral IR thermographyRead onDownload ZIP-File (10174 kB)Infrared thermography offers precise temperature measurement in various wavelength ranges such as short wave infrared (SWIR), mid wave infrared (MWIR) and long wave infrared (LWIR) of a wide range of materials.

![TarisIR® mini – When Size Matters TarisIR® mini – When Size Matters]() 2024-09-10TarisIR® mini – When Size Matters!The latest model in InfraTec's compact camera series impresses with excellentimage quality and smallest dimensions.Read onDownload ZIP-File (10756 kB)

2024-09-10TarisIR® mini – When Size Matters!The latest model in InfraTec's compact camera series impresses with excellentimage quality and smallest dimensions.Read onDownload ZIP-File (10756 kB)The TarisIR® mini is the latest radiometrically calibrated infrared camera in InfraTec's portfolio. It is designed for universal use and – with the associated IRBIS® software – enables entry-level access into stationary thermography at an excellent price-performance ratio.

![]() 2024-08-01Integrated Software Development Kit for Zoom CameraThe ImageIR® 6300 Z zoom infrared camera is now even more flexible than before.Read onDownload ZIP-File (10220 kB)

2024-08-01Integrated Software Development Kit for Zoom CameraThe ImageIR® 6300 Z zoom infrared camera is now even more flexible than before.Read onDownload ZIP-File (10220 kB)The ImageIR® 6300 Z zoom infrared camera is smaller, lighter, does not require any time-consuming lens changes – and now also boasts an integrated Software Development Kit (SDK). With technical features such as the 7.5x zoom lens with motor focus (built in as standard) and its compact size, the radiometrically calibrated zoom camera was already a force to be reckoned with.

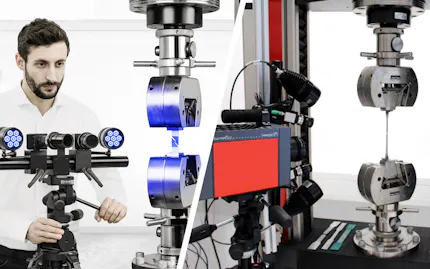

![Online Event - Thermography and Digital Image Correlation Online Event - Thermography and Digital Image Correlation]() 2024-07-12Online Event: Thermography and Digital Image CorrelationA winning team in the materials and components testing fieldRead onDownload ZIP-File (2013 kB)

2024-07-12Online Event: Thermography and Digital Image CorrelationA winning team in the materials and components testing fieldRead onDownload ZIP-File (2013 kB)In the field of materials testing, numerous methods have been established including infrared thermography. Often, it is the combination of different methods that enables the desired results for component characterisation. For example, you can analyse displacements and mechanical deformations of material samples and components parallel with its thermal reaction.

![Thermography Compact online event Thermography Compact online event]() 2024-07-09Thermography Compact – Enter the World of Infrared Technology (August 2024)Experience thermography – technical lectures and demonstrations plus professional exchanges.Read onDownload ZIP-File (2164 kB)

2024-07-09Thermography Compact – Enter the World of Infrared Technology (August 2024)Experience thermography – technical lectures and demonstrations plus professional exchanges.Read onDownload ZIP-File (2164 kB)On 28 August 2024, interested parties and thermographers from science and industry will have the opportunity to learn more about the possibilities of thermography in the demanding field of research and development.