IRBIS® 3 active

Active Thermography Software

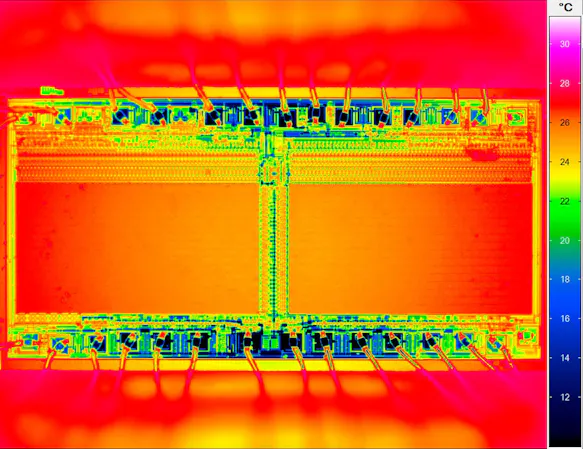

The active thermography software IRBIS® 3 by InfraTec is a modern and universally usable tool for thermographic material testing. Active thermography allows for a non-destructive detection of material defects, such as joint flaws, blowholes, cracks or delamination, by inserting a thermal pulse into the test object.

Thermography sequences, which are synchronised with the excitation unit, are edited and displayed as a false colour result image by means of a specially developed analysis procedure. Thus, even small defects can be recognised repeatedly and reliably. The selection of the implemented evaluation algorithm largely depends on the material and geometry of the test object as well as on the type of defect to be detected.

Besides InfraTec's high-end camera series ImageIR®, the utilisation of powerful microbolometer cameras for active thermography is another completely unproblematic solution nowadays. The excellent geometrical and thermal resolution of the camera series VarioCAM® High Definition as well as their fast image refresh rate and trigger ability are a perfect basis for the solution of a variety of problems.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Features of IRBIS® 3 active

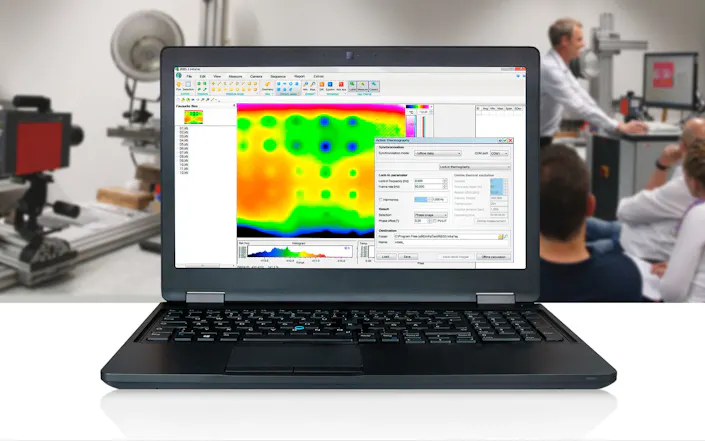

Comfortable data evaluation possibilities of image sequences

Storage of input parameter

Calculation of phase and amplitude images

Analysis with different active thermography methods: Quotient Method, Pulse Phase Thermography, Lock-In-Thermography

Algorithms independent of emissivity

Storage of input parameters for different test objects

Analysis Methods of IRBIS® 3 active

Quotient method

The heat flow of the test object will be analysed by means of incline or decline of the surface temperature.

Pulse Phase Thermography (PPT)

The temperature curve will be analysed depending on different frequencies (n = 1, 2, 3 ...). One amplitude image and one phase image will be established for each frequency.

Lock-in Thermography (LIT)

The sequences of periodical excitation of the test object will be analysed.

Automated Lock-In measurement with E-LIT from InfraTec

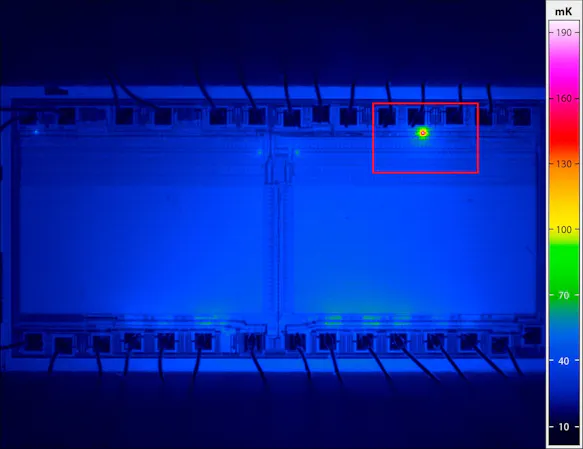

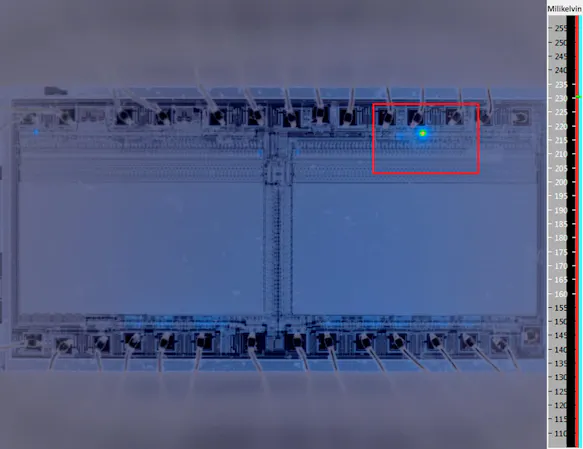

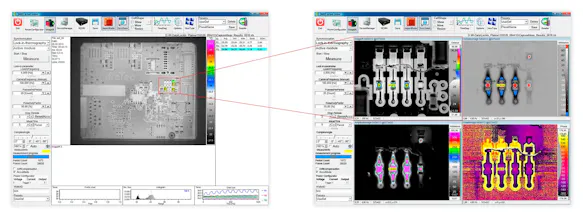

Lock-in Thermography in Electronics and Electrical Engineering

By means of lock-in analysis procedure of InfraTec's IRBIS® 3 active, errors that only cause mK or μK deviations can be reliably detected and assigned to their location: